ASSEMBLY

TW120 01/11 Assembly Section 3-6

© 2011 Alamo Group Inc.

ASSEMBLY

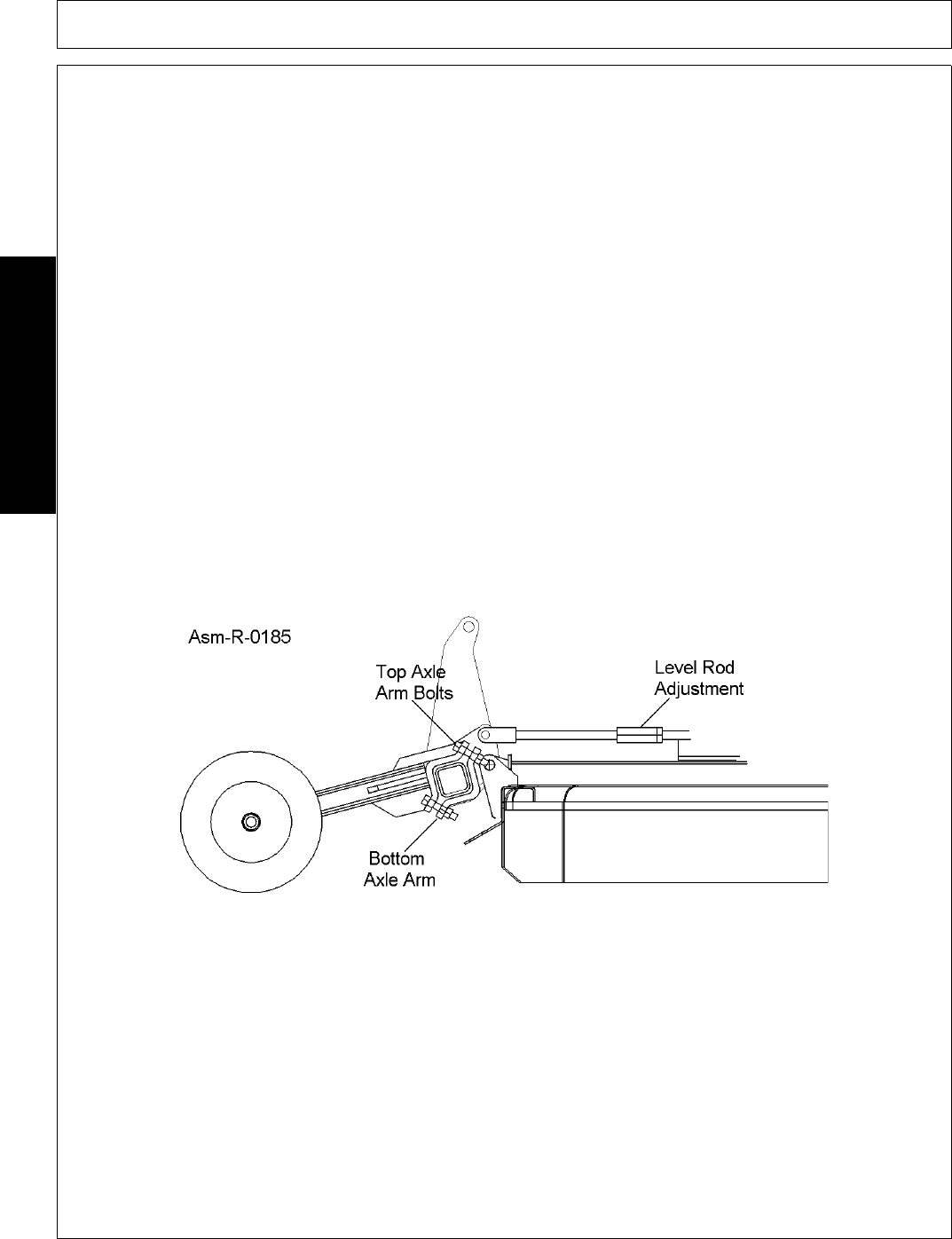

CUTTER LEVELING

Often when the unit is first assembled and placed on a horizontal surface, the cutter is not level front to rear or

side to side. Proper leveling must be obtained in order to prevent skid shoes from plowing in the dirt and to

obtain a clean, level cutting performance.

Leveling must first be conducted left to right with measurements being taken at the front corner of the mower

deck from the ground to the bottom of the skid shoe. If the two dimensions measured are not equal, the cutter

must be leveled left to right. This may be done by the following procedure:

Using the axle arm assembly on the high side of the cutter deck, loosen the bottom two clamp bolts one or two

turns and tighten the top two clamp bolts. This should be done in an alternating sequence, measuring the

height of the skid shoes after each adjustment. Continue with this process until no additional leveling from side

to side can be obtained. If the unit is still not level, work must then be done on the axle arm assembly which is

on the low side of the cutter.

This cannot be done until the weight of the cutter is removed from the axle arm by placing a jackstand

underneath the cutter and putting the hydraulic valve in the float position (or loosening the ratchet hack if the

hydraulic cylinder is not used), which will then release pressure on the cylinder and the load on the axle arm.

Once this has been done, the axle arm may be adjusted by first loosening the top two bolts one or two turns

and then tightening the bottom two bolts. After each adjustment, the cutter should be lifted off of the jackstand

using the hydraulic cylinder or ratchet jack and then placed back on the jackstand if further adjustment is

needed. This process should be continued until the cutter becomes level left to right.

Once leveling from side to side has been completed, leveling from front to rear should be done. To level the

cutter from front to rear, the leveling rod which links the tongue and the rear axle must be adjusted. To lower

the front, lengthen the level rods and to raise the front, shorten the level rods. IMPORTANT: Adjust level rods

the same length to maintain equal tension in rods. Improper adjustment may cause rods to snap or bend.

Once machine has been leveled according to directions, the cutting height can be set.