EXHAUST REQUIREMENTS

While it is important to supply the proper amount of clean air to the cylinder, it is equally important to

discharge the gases of combustion. If these gases remain in the cylinder, the next cycle cannot burn the

fuel completely. This condition results from excessive backpressure that is caused by any one or

combination of these conditions:

a. Exhaust pipe diameter too small.

b. Exhaust pipe too long.

c. Excessive number of sharp bends in exhaust system.

d. Inadequate muffler.

e. Incorrect construction of muffler resulting in high resistance.

f. Obstruction in exhaust system.

Backpressure must not exceed 20" (water column) on naturally aspirated engines or 27" (water column)

on turbo-charged models.

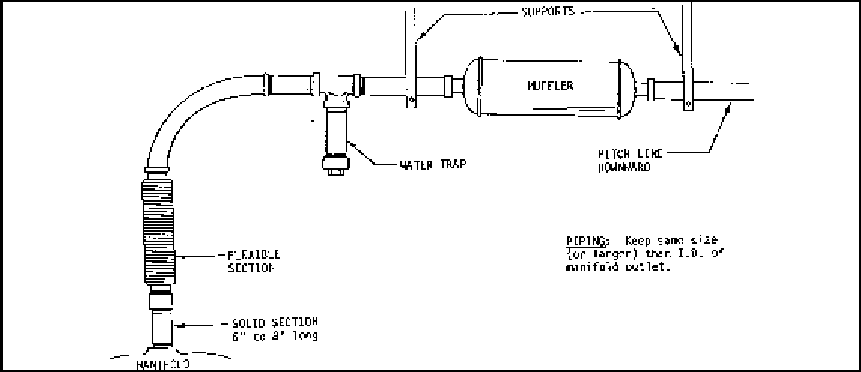

EXHAUST PIPING

Exhaust lines should be as short and straight as possible, since extended runs and elbows tend to clog

with carbon and resist the flow of gases. Each pipefitting and elbow will hinder the exhaust flow.

The muffler should be as close to the engine as possible, since it will clog up with carbon if operating

temperature is too low.

NOTE: Never mount the muffler on the manifold.

A flexible coupling must be provided between the exhaust line and the manifold. However, a short, solid

section of pipe between 6" or 8" long should be placed between the connection of the manifold and the

flexible coupling,.

Water, one of the by-products of combustion, will be present in the exhaust piping or muffler. This water

must be kept from draining back into the engine. This can be done by slanting the horizontal section of the

exhaust pipe downward slightly, away from the engine. A water trap consisting of a tee extension with a

drain cock should be provided.

FIGURE 6-1: SCHEMATIC OF EXHAUST SYSTEM