7 - 25

Lubricate the new seal prior to installation with a

petroleum jelly.

Wrap the shaft spline with a thin plastic or cellophane

tape to prevent damage to the new seal lip during

installation.

Slide the seal over the shaft and press it into the

housing bore. Be careful not damage the seal. The

seal should seat against the retaining ring.

The displacement control shaft seal and bypass

actuator shaft seal may be replaced following similar

procedures.

Internal Repair

1. Drain the oil by removing the breather assembly

and positioning the IHT so that the breather port is

down to allow the oil to drain thoroughly.

2. Position and secure the IHT with the upper housing

down to allow access to the ten housing assembly

cap screws.

3. Remove the eight rear housing assembly cap

screws.

4. Remove the ten bottom cover assembly screws.

5. Remove the torques head cap screw holding the

brake arm to the transaxle case.

6. Remove the bottom and rear covers from the

transaxle.

NOTE:

The sealant will make the covers difficult to

remove.

7. All components should remain in the upper

housing (positioned down).

8. Remove the brake gear from the brake shaft.

9. Remove the oil seals from the brakes shaft. Push

out the brake shaft to remove the support bearing.

NOTE:

Prior to reassembly the lower and rear covers

must be thoroughly cleaned and old sealant must be

removed.

NOTE:

The lip seals must not be re-used during reas-

sembly.

10.Inspect the final drive gear teeth for excessive

wear or damage.

11.Inspect the brake gear internal splines for

excessive wear or damage. See Figure 24.

12.Inspect the brake cam for excessive wear and

damage.

Replace brake gear and cam as a complete kit if

excessive wear or damage is found, and inspect all

other mating parts.

13.Using a 9/16" socket (or box end) wrench, remove

the three assembly bolts retaining the center

section in the upper housing.

14.Remove the center section assembly from the

housing. The pump block assembly should remain

in the upper housing on the input shaft, but may

stick to the center section. Check the check valve

plate bolt torque, but do not remove. Two styles of

check plates have been used, one has three bolts

while the other has four.The one with four bolts

should be torqued from 170 to 240 in-lbs.

(19.2-27.1 Nm) while the one with three bolts

should be torqued from 135 to 185 in-lbs

(15.2-20.9 Nm)

15.Remove the motor block assembly from the motor

shaft and inspect for unusual wear or damage. The

pistons should fit with very little side clearance in

the block bores, but must side freely.

NOTE:

The correct bore diameter for the block is

0.6776 to 0.6784 and the pistons should be 0.6767 to

0.6770.

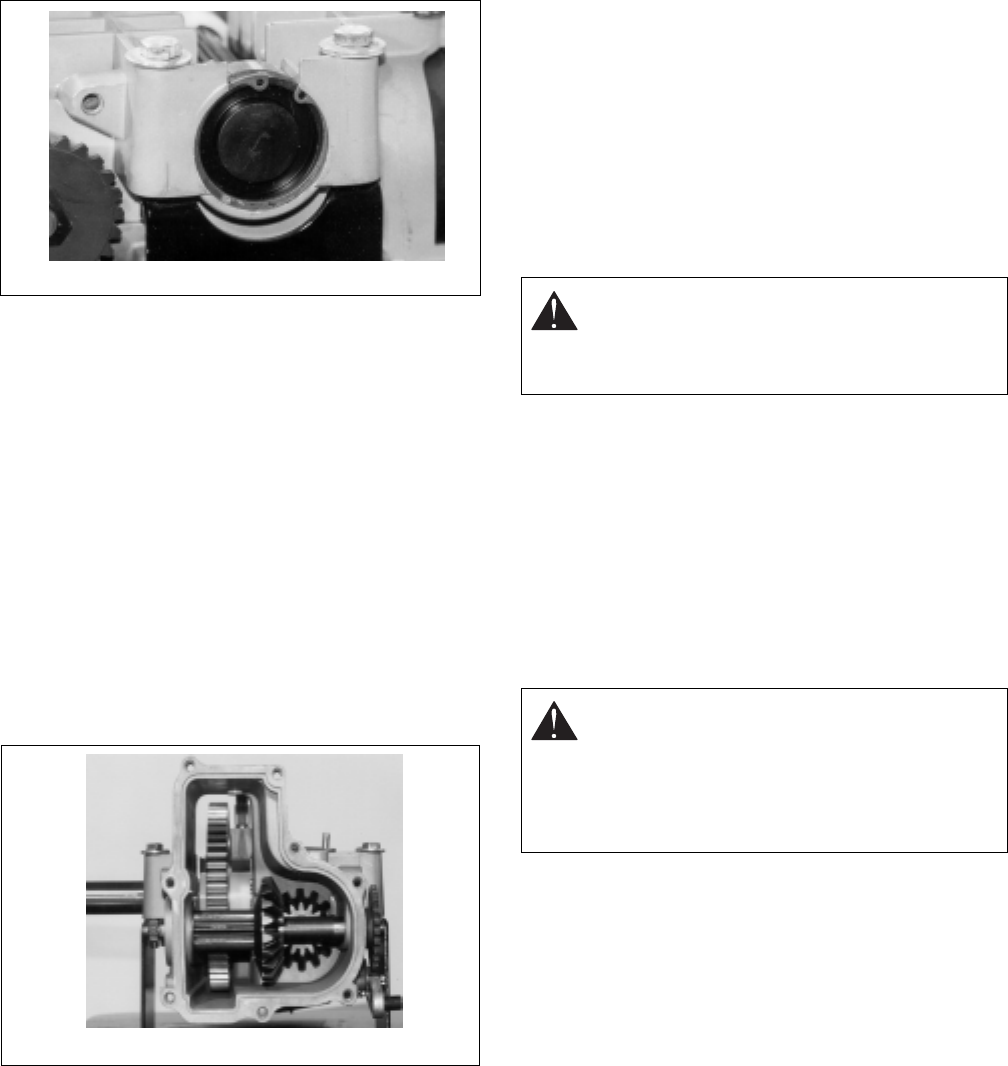

Figure 23

Figure 24

CAUTION:

The pump and motor piston

springs may push the center section

assembly out of position while you remove

these bolts.

CAUTION:

The aligning pins, motor shaft,

bypass plate, pump block and motor block

assemblies are NOT retained to the center

section or the upper housing and may

become separated from the assembly during

removal.