9

FERTILIZER

Powder 3-5 3'-4'

Granular 3-5 8'-10'

Pelleted 3-5 10'-12'

Organic 6-8 6'-8'

GRASS SEED

Fine 3-4 6'-7'

Coarse 4-5 8'-9'

ICEMELTER 6-8 10'-12'

TYPE SPREAD

MATERIAL FLOW SETTING WIDTH

APPLICATION CHART

OPERATING SPEED -3MPH.(100ft.in23seconds)

IMPORTANT: Application rates shown in the chart are

affected by humidity and by the moisture content of

the material (granular and pellet). Some minor setting

adjustments may be necessary to compensate for this

condition.

CHECK FOR LOOSE FASTENERS

1. Beforeeachusemakeathoroughvisualcheckofthe

spreaderforanyboltsandnutswhichmayhaveloosened.

Retightenanylooseboltsandnuts.

CHECK FOR WORN OR DAMAGED PARTS

2. Checkforwornordamagedparts before eachuse.

Repair or replace parts if necessary.

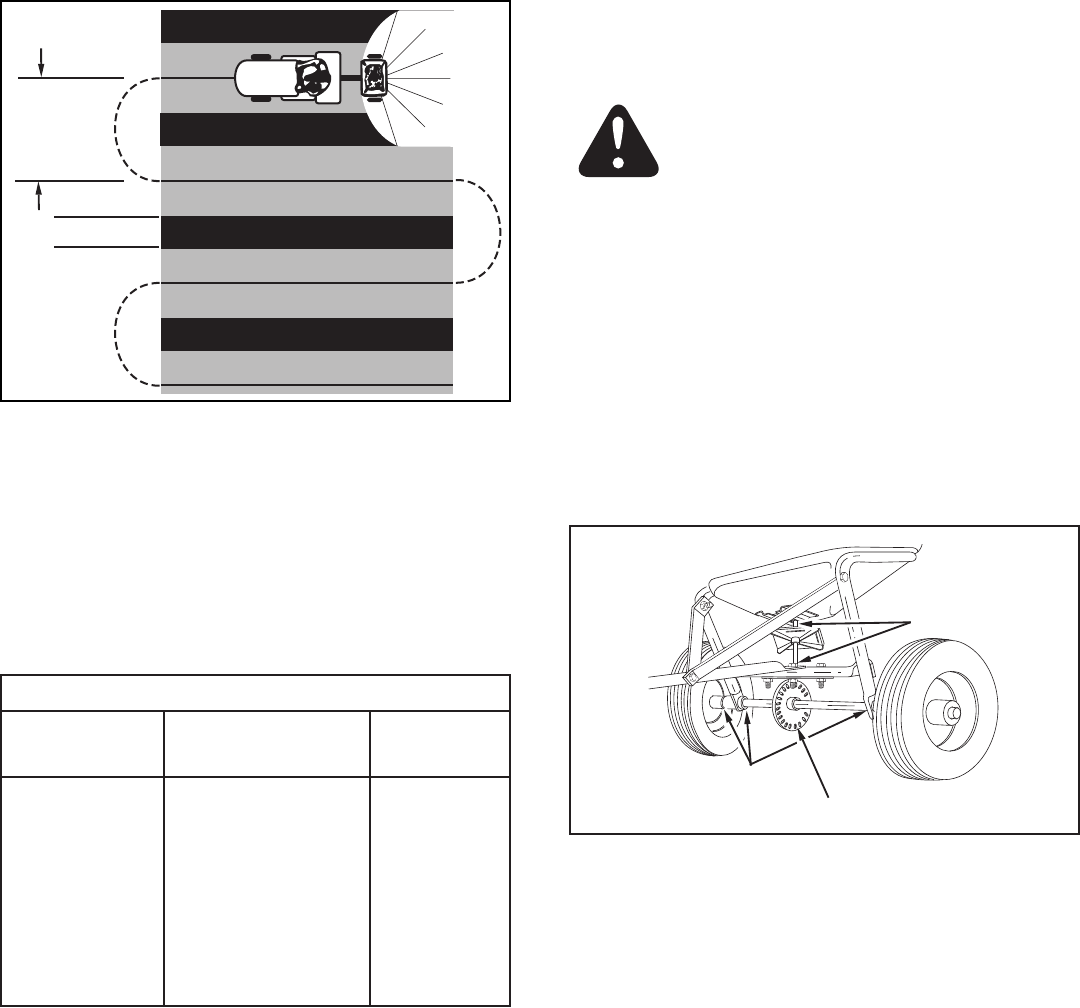

FIGURE 19

1. Rinse inside of hopper and exterior of spreader and dry

offbeforestoring.

2. Storeinaclean,dryarea.

CAUTION: DO NOT inatetiresbeyondthe

maximumrecommendedpressureprintedon

side of tire.

CLEANING

4. Rinse inside of hopper and exterior of spreader and dry

offbeforestoring.

LUBRICATE (Seegure19)

5. Lightly apply automotive grease as needed to the

sprocket and gear.

6. Oilthenylonbushingsontheverticalsprocketshaft

andontheaxleatleastonceayear,ormoreoftenas

needed.

7. Oilrighthand(idler)wheelbearingatleastonceayear

ormoreoftenasneeded.

MAINTENANCE

GREASE

OIL

OIL

STORAGE

1. If the axle, slotted gear and sprocket assembly is

disassembled,markdownthepositionsofthepartsas

theyareremoved.Thedrivewheelandsprocketpositions

inrelationtotheslottedgeardeterminewhichdirection

thespreaderplatewillspin.Besuretoreassemblethem

intheiroriginalpositions.(Refertogure4onpage5.)

Useshimwashers(Ref.no.21onpages10and11)

asneededforminimumbacklash.Addgreasetogear

and sprocket.

SERVICE AND ADJUSTMENTS

FIGURE 18

OVERLAP

REFER

TO

CHARTS

CHECK TIRE INFLATION

3. Checkiftiresareadequatelyinatedbeforeeachuse.Do

notinatebeyondmaximumrecommendedpressure.