38

8. Maintenance

English

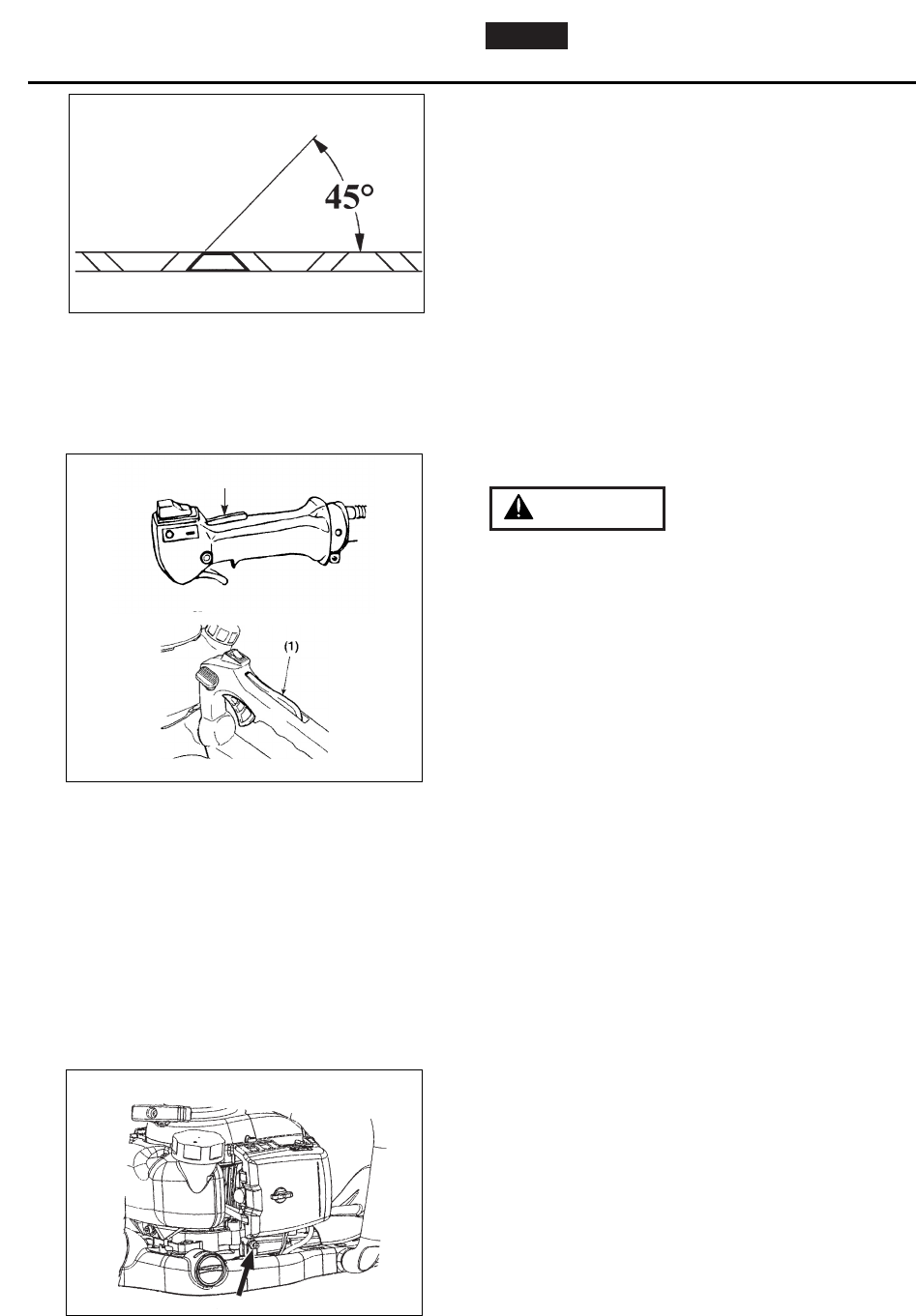

■ SHARPENING (MA8)

Always keep the file or sharpener at an angle of 45° to

the blade, and:

• Always grind in the direction of the cutting edge;

• Note: files cut only in one direction; lift the file from

the blade when returning to start a new pass;

• Remove all burr from the edge of the blade with a

slip stone;

• Remove as little material as possible;

• Before refitting the sharpened blades, remove filings

and then apply grease.

Do not try to sharpen a damaged blade: change it or

take it to a Service dealer.

■ SAFETY LOCK (MA7)

•Stop operation when the safety lock is defective.

• Safety lock is the device not to accelerate the throttle

lever without intention. While pushing the safety

lock, you can accelerate the throttle lever.

1. Check if the throttle lever does not move when you

do not push the safety lock.

2. Check if the throttle lever moves when you grasp or

release it while pushing the safety lock.

3. Check if the safety lock returns to its original position

when you release your hand from safety lock.

• If you find any defects at the checks above, contact

your nearest servicing dealer for repair.

(1) Safety lock

■ REDUCTION GEARBOX

Refill gear housing every 50 working hours (MA9).

Use greese pump. Feed greese until it comes out of

the base of blades.

Grease nipple: A type

WARNING

MA9

MA8

(1)

MA7