7

8. If the wheels can still be turned when you engage

the drive control, loosen the jam nut on the drive

cable and thread the cable in one turn. Recheck the

adjustment and repeat if needed.

9. Tighten the jam nut to secure the cable when

correct adjustment is reached.

NOTE: For further details, refer to the Adjustment

section on page 17.

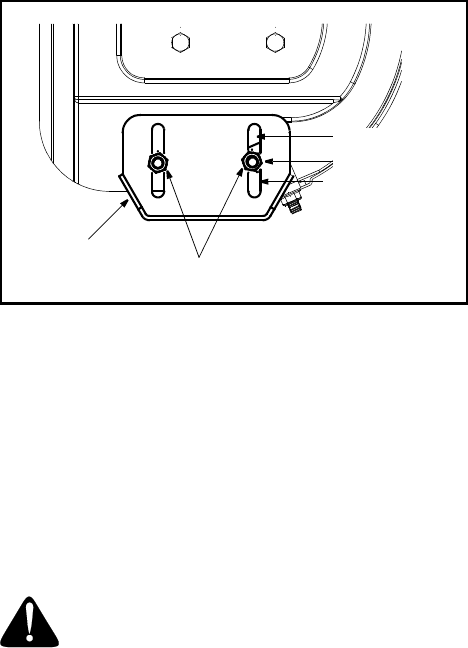

Skid Shoe

Locate the shave plate and the skid shoes in Figure 7

on page 8. The space between this shave plate and

the ground can be adjusted. For close snow removal,

place skid shoes in the low position. Use middle or

high position when area to be cleared is uneven.

IMPORTANT:

It is not recommended that you operate

this snow thrower on gravel as loose gravel can be

easily picked up and thrown by the auger causing

personal injury or damage to the snow thrower.

If for some reason, you have to operate the snow

thrower on gravel, keep the skid shoe in the highest

position for maximum clearance between the ground

and the shave plate.

1. Adjust skid shoes by loosening the four lock nuts

and carriage bolts and moving skid shoes to

desired position. See Figure 6.

2. Make certain the entire bottom surface of skid

shoes are against the ground to avoid uneven wear

on the skid shoes.

3. Tighten nuts and bolts securely.

Figure 6

Tire Pressure (Pneumatic Tires)

The tires are over-inflated for shipping purposes.

Check the tire pressure before operating the snow

thrower. Refer to the tire side wall for tire

manufacturer’s recommended psi and deflate (or

inflate) the tires as necessary.

NOTE: If the tire pressure is not equal in both tires, the

unit may pull to one side or the other and the shave

plate will not sit level on the ground.

WARNING: Under any circumstance do not

exceed manufacturer’s recommended psi.

Equal tire pressure should be maintained at all

times. Excessive pressure when seating

beads may cause tire/rim assembly to burst

with force sufficient to cause serious injury.

Refer to sidewall of tire for recommended

pressure.

Four-Way Chute Control™

The chute control lever may need to be lubricated to

reduce its break-in period. Vegetable oil, petroleum jelly

or motor oil can be used as lubricant.

IMPORTANT:

This unit is shipped with engine oil in the

engine, but without gasoline. After assembly, see

OPERATION section of this manual for fuel selection

and fill-up.

High Position

Low Position

Middle Position

Lock Nut

Skid Shoe