13

SECTION 6: MAKING ADJUSTMENTS

WARNING: NEVER attempt to clean

chute or make any adjustments while

engine is running.

Chute assembly adjustment

The distance snow is thrown can be controlled by

adjusting the angle of the top section of the chute

assembly.

Skid shoe adjustment

The space between the shave plate and the ground

can be adjusted. Refer to the Final Assembly and

Adjustments section.

Traction control clutch adjustment

Refer to the Final Assembly and Adjustments section

to adjust the traction control clutch. If you are

uncertain that you have reached the correct

adjustment, the adjustment can be physically checked

as follows.

• With the snow thrower tipped forward (be certain to

drain the oil and gasoline or drain the oil and place

plastic film under the gas cap if the snow thrower

has already been operated), remove the frame

cover underneath the snow thrower by removing six

self-tapping screws.

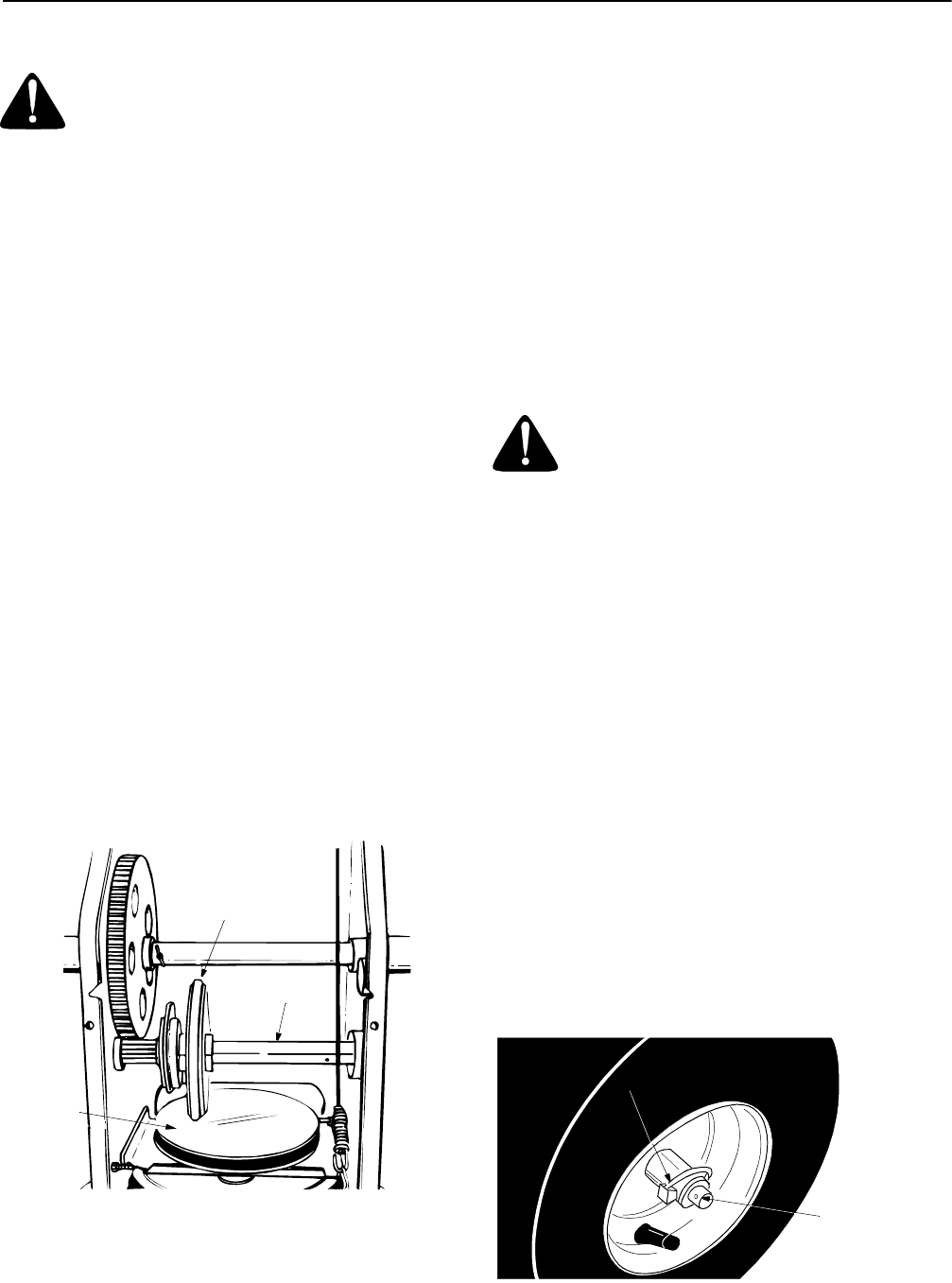

• With the traction control clutch released, there must

be clearance between the friction wheel and the

drive plate in all positions of the shift lever. With the

traction control clutched engaged, the friction wheel

must contact the drive plate. See Figure 17.

Figure 17

• If adjustment is necessary, loosen the lock nut on

the traction control cable and thread the cable in or

out as necessary. Tighten the lock nut to secure the

cable when correct adjustment is reached.

Reassemble the frame cover.

NOTE:

If you placed plastic under the gas cap, be

certain to remove it.

Auger clutch adjustment

To adjust the auger clutch, refer to Final Assembly and

Adjustments section.

Carburetor adjustment

WARNING: If any adjustments are made

to the engine while the engine is running

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude and load.

Refer to the separate engine manual packed with your

unit for carburetor adjustment information.

Drive wheels

The wheels may be adjusted for two different methods

of operation. The adjustment is made by placing the

klick pins in one of two different holes on the right side

of the unit. See Figure 18.

• One Wheel Driving—On the right side of the unit,

place klick pin in the outside axle hole only. Do not

place pin through wheel hub. This position gives

power drive to the left wheel only, making the unit

easier to maneuver.

• Both Wheels Driving—Rotate wheel assembly to

align hole in hub with inner hole on axle shaft. Insert

klick pin in hole. Outer axle shaft hole should be

visible. See Figure 18.

Figure 18

Friction

Wheel

Gear Shaft

Drive

Plate

Outside

Hole in Axle

Klick Pin in Hub

and

Inner

Axle

Hole

Hole