8

Model 345

1. Attach spark plug wire to spark plug. Make

certain the metal loop on the end of the spark

plug wire (inside the boot) is fastened securely

over the metal tip on the spark plug.

2. Make certain all controls are in the neutral

position (released). (See Figure 8).

3. Place the engine speed control in the START

position.

4. Push primer two (2) or three (3) times (see

Figure 9). Wait about two (2) seconds between

each push.

NOTE:

Primer may be needed to restart a warm

engine after a short shutdown.

5. Stand at side of tiller. Grasp the starter handle

and pull out slowly, until it pulls slightly harder.

Let rope rewind slowly.

6. Pull rope with a rapid full arm stroke. Do not

allow handle to snap back. Allow it to rewind

slowly while keeping a firm hold on the starter

handle.

NOTE:

If engine fails to start after three (3) pulls,

push primer two (2) times and pull starter rope again.

7. Repeat steps 4 and 5 until engine starts. Refer

to engine manual for additional engine

information.

NOTE:

After starting engine and prior to using the

tiller, be certain to check the clutch adjustment as

described in “Checking the Clutch Adjustment”

section of the Assembly Instructions.

TO STOP ENGINE

1. Move throttle control lever to STOP or OFF

position.

2. Disconnect spark plug wire from spark plug and

ground against the engine to prevent accidental

starting while equipment is unattended.

HOW TO USE YOUR TILLER

Your tiller is a precision built machine designed for

seed bed preparation, cultivating, furrowing and

mulching. It is engineered to minimize the hardest

work in the vegetable or flower garden, to till the soil

for planting and cultivating, and to perform many

other useful labor saving tasks in the garden. With

the proper amount of care and maintenance, this

machine will provide the owner with many years of

service.

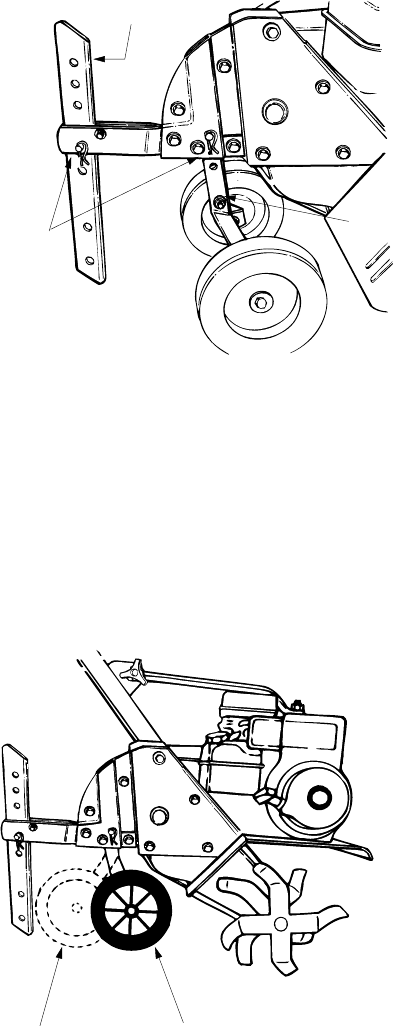

WHEEL POSITION

The tiller is shipped with the wheels adjusted such

that the unit sits level. While tilling, as the tines

enter the ground and the front of the tiller lowers,

the wheels must be raised to level the unit, which is

essential for proper engine operation. This

adjustment is made by removing the clevis pin and

hairpin clip from wheel yoke, raising the wheels to

the desired height, and replacing the clevis pin and

hairpin clip. (See Figure 10.)

Figure 10

CONTROLLING SPEED AND TILLING

DEPTH

1.

Wheel Yoke Adjustment:

Place wheel yoke so

that the wheels are forward (nearest point

between wheels and tines) for shallow tilling,

cultivating and transport. The forward speed will

increase. Turn yoke around (farthest point

between wheels and tines) for deep tilling.

Forward speed will decrease. (See Figure 11.)

Figure 11

Wheel

Yoke

Depth Stake

Hairpin

Clip and

Clevis Pin

Wheel Yoke in this

position for

deep tilling.

Wheel Yoke in this

position for shallow tilling,

cultivating, and transport.