21

18

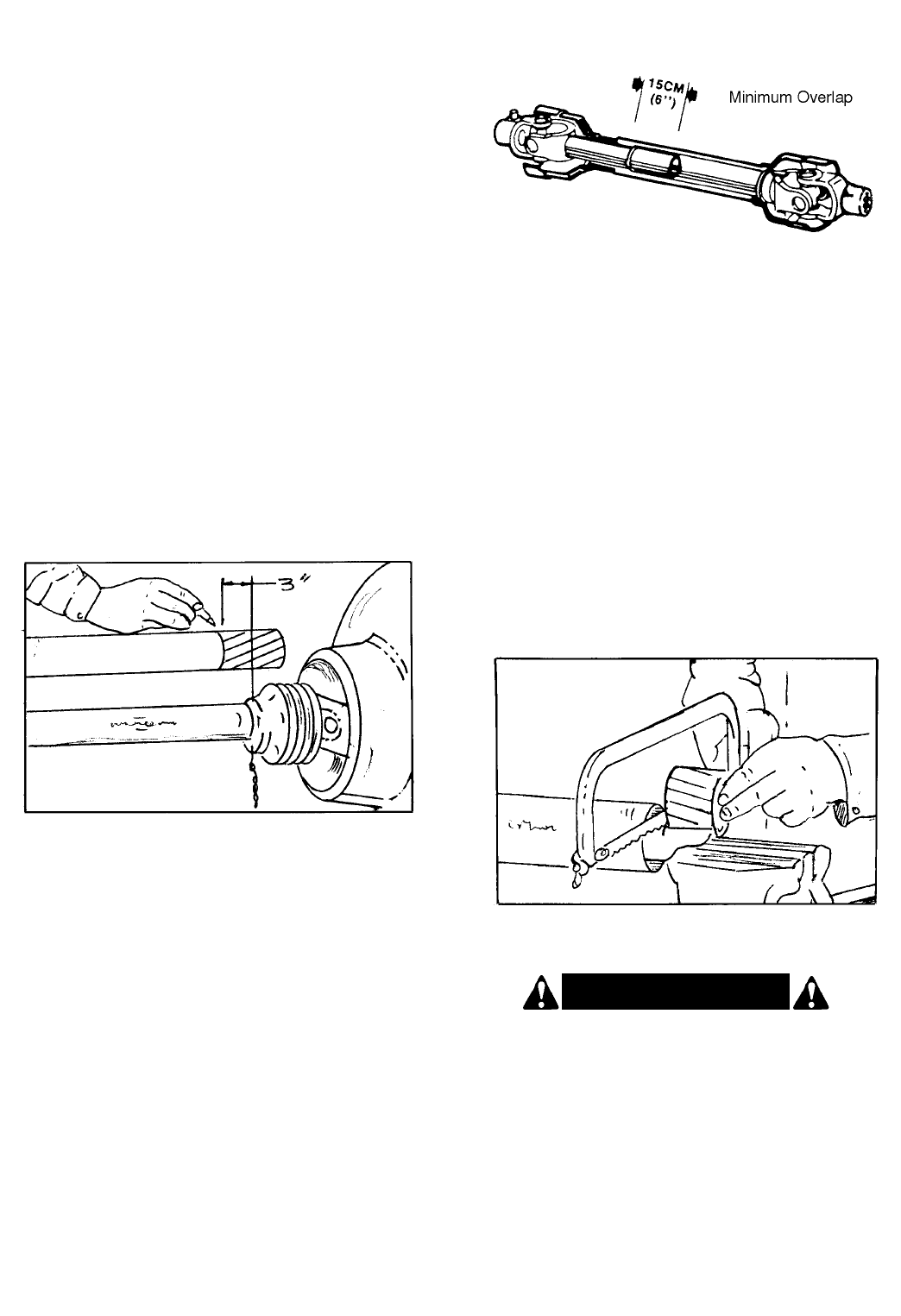

Figure 2.

Figure 3.

NOTE: The use of a PTO over-running clutch or exten-

sion could require that the PTO driveline be shortened a

considerable amount. If this is done, the driveline halves

may separate when the cutter is lowered to the ground or

when operated on rough ground.

An optional special driveline that is equipped with an over-

running clutch is recommended (see optional equipment).

1. Raise and lower the cutter to determine position with

greatest distance between the PTO shaft and gearbox

input shaft. Shut tractor off, leaving cutter in position

of greatest distance between shafts. SECURELY

BLOCK CUTTER IN POSITION.

2. Hold driveline sections parallel to each other and

check for minimum 6” (15cm) overlap. If driveline

has been marked for cutting, overlap will be the

distance between the two marks. If driveline has less

than minimum overlap, do not use. Contact

authorized dealer.

3. If driveline must be cut to a shorter length, clamp

driveline in a well padded vise to prevent damage to

the shield. Cut off shield where marked. Using cut-off

section of shield as a guide, cut shaft the same

amount. (Figure 4.)

4. Repeat the procedure to the other driveline half.

Remove all burrs and cuttings.

5. Apply multi-purpose grease to inside of outer (female)

driveline section. Assemble driveline and install on

tractor and cutter. Pull on each driveline section to be

sure yokes lock into place. Make certain driveline

shielding is in place and in good condition.

Figure 4.

W ARNING!

When attaching PTO yoke to tractor PTO shaft, it is

important that spring-activated locking pin or balls

operate freely and are seated in groove on PTO shaft.

A loose shaft could slip off and result in personal

injury or damage to equipment.

6. Carefully raise and lower the cutter and check to be

sure the PTO assembly does not jam. If it does, cut

equal amounts from each half of the PTO assembly.

INSTRUCTIONS (continued)

In some cases it will be necessary to shorten the PTO

assembly to match your particular tractor. The following

procedure should be used:

1. Raise the tractor 3-pt. hitch so the input shaft of the

cutter gearbox is in line with the PTO shaft on the trac-

tor. Shut down tractor, leaving cutter in position of

shortest distance between shafts. SECURELY

BLOCK CUTTER IN POSITION.

2. Pull driveline apart. Attach outer (female) section to

tractor PTO shaft. Pull on driveline section to be sure

that yoke locks into place.

3. Hold driveline sections parallel to each other to

determine if too long. Each section should end

approximately 3” (76mm) short of reaching universal

joint shield on opposite section. If too long, measure

3” (76mm) back from universal joint shield and mark

on opposite section (Figure 3). Do this for both sec-

tions. DO NOT CUT UNTIL STEPS 4 AND 5 ARE

CHECKED.

OPERATING TECHNIQUE

Power for operating cutter is supplied by tractor PTO.

Operate PTO only at 540 rpm gear range. Know how to

stop tractor and cutter quickly in case of an emergency.

Engage PTO at a low engine rpm to minimize stress on

the drive system and gearbox. Place tractor in gear and

proceed forward. Advance tractor throttle to 540 PTO

RPM. Tractor forward speed should be controlled by

gear selection, not engine speed. For maximum cutting

efficiency, forward speed should allow cutter to maintain

a constant, maximum blade speed. If cutter stalls or

tractor engine bogs, disengage PTO. Before re-engag-

ing PTO, position cutter in a cut area and reduce tractor

throttle to idle. If cutter continuously stalls, select lower

tractor gear and/or increase cutting height.

Blade rotation is counterclockwise causing cut material

to discharge to the left side of cutter forming a windrow.

To shred and dissipate this windrow, tractor should be

driven in a counterclockwise direction throwing material

to the uncut area. The windrowed material will be recut

on each new pass. Tractor tire tracks are cut more effi-

ciently when tractor is traveling in a clockwise direction

especially when cutting height is high. Larger brush

should be cut in the center of cutter. Always cut up and

down the face of slopes, never across.

Gearbox protection is provided by a shearbolt. The

shearbolt will shear when excessive torsional loads are

encountered.

Proper ground speed will depend upon the terrain, the

height, type and density of material to be cut.

Normally, ground speed will range from two to five mph.

Tall dense material should be cut at a low speed; thin

medium-height material can be cut at a faster ground

speed.

When engaging the PTO, the engine speed should

always be low. Once the PTO is engaged and ready to

start cutting, raise the PTO speed to 540 RPM and main-

tain throughout mowing operation. ALWAYS operate the

PTO at 540 RPM. This is necessary to maintain proper

blade speed to obtain a clean cut.

Under certain conditions, tractor tires may roll some

grass down and prevent it from being cut at the same

height as the surrounding area. When this occurs,

reduce your ground speed, but maintain PTO at 540

rpm. The lower ground speed will permit grass to at least

partially rebound.

Pass diagonally through sharp dips and avoid sharp

drops to prevent “hanging up” tractor and cutter.

Practice will improve your skills in maneuvering rough

terrain.

O P E R ATING TIPS

SHREDDING

For shredding, it is better to set the cutter lower at the

rear. How much lower depend on the material to be

shredded. Determine the best setting for your situation

by experimenting.

Extremely tall material should be cut twice. Set cutter at

a higher cutting height for the first pass. Then cut at

desired height at 90˚ to the first pass.

Remember, sharp blades produce cleaner cuts and

require less power.

Analyze area to be cut to determine the best procedure.

Consider height and type of grass and terrain type; hilly,

level or rough.

Plan your mowing pattern to travel straight forward

whenever possible. Mow clockwise around fields when

necessary to minimize streaking on corners.

UNEVEN TERRAIN

Under some conditions, grass will not rebound enough

to be cut evenly. In general, lower cutting heights give a

more even cut with less tendency to leave tire tracks.

However, it is better to cut grass frequently rather that

too short. Short grass deteriorates rapidly in hot weather

and invites weed growth during growing seasons. Follow

local recommendations for the suitable cutting height in

your area.

IMPORTANT

Vibration tends to loosen bolts during operation. All

hardware should be checked regularly to maintain

proper torque. It is a good practice to check cutter

before each operation to ensure all hardware is

secure.

OPERATION INSTRUCTIONS (continued)

W ARNING!

Do not operate on steep slopes.

Do not stop, start or change directions suddenly on

slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Watch or hidden hazards on the terrain during

operation.

W ARNING!

Inspect area to be cut and remove stones,

branches, or other hard objects that might be

thrown, causing injury or damage.