17 22

WARNING

To prevent serious injury or death:

Si no lee ingles, pida ayuda a alguien que si lo lea para

que le traduzca las medidas de seguridad.

• Read and understand Operator’s Manual before using.

Review annually.

• Do not permit riders on the tractor or mower. Never

carry children on tractor seat.

• Do not allow children to operate mower.

• Operate only with guards installed and in good condition.

• Keep away from moving parts.

• Operate only with tractor equipped with ROPS and

seatbelts.

• Before mowing, clear debris from mowing area.

• Do not operate in the raised position.

• Stop engine, set brake and wait for all moving parts to

stop before dismounting.

• Support mower securely before working beneath unit.

• Transport with clean reflectors, SMV and working lights

as required by federal, state, and local laws.

M100

ITEM 9 – Part No. 101157

SAFETY SIGNS (continued)

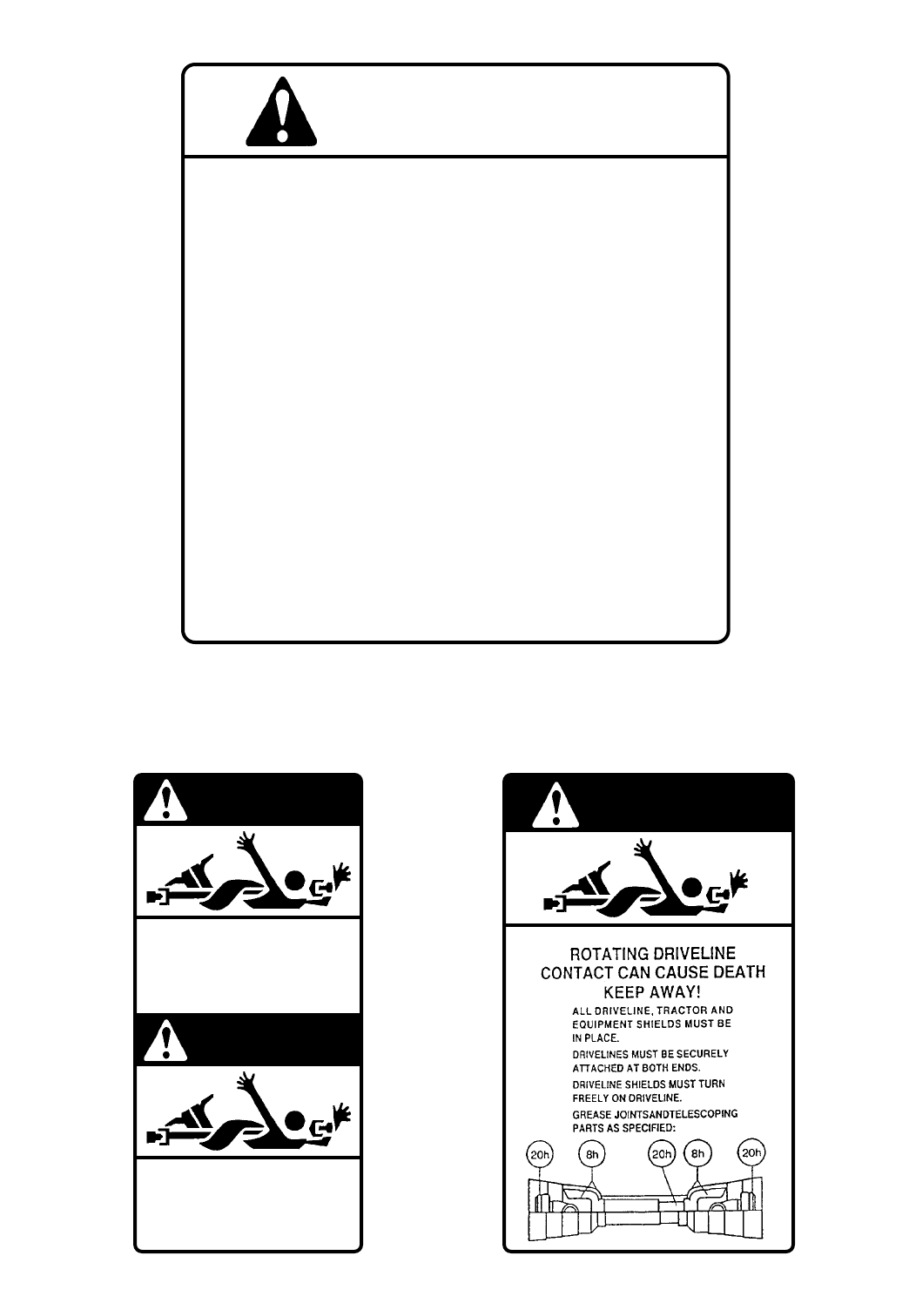

DRIVELINE SAFETY SIGNS

DANGER

SHIELD MISSING

DO NOT OPERATE

DANGER

SHIELD MISSING

DO NOT OPERATE

DANGER

WARNING!

A loose shaft could slip off and result in personal

injury or damage to the mower. When attaching the

driveline yoke to the tractor PTO shaft, it is important

that the spring activated twist collar turns freely and

that the locking pin is seated on the PTO shaft groove.

WARNING!

Before operating the mower check to make sure the

driveline will not bottom out or become disengaged.

See figure 6.

Figure 5

Front Gauge Wheel Clearance

Figure A Figure B

Figure C Figure D

Figure 6

Driveline in maximum compressed position

ADJUSTING DRIVELINE LENGTH

1. Slide the driveline together until it “bottoms out.”

2. Apply colored tape to the inner plastic shield tube

1

/

8

”

from the end of the outer shield tube.

3. Reconnect the driveline to the tractor PTO shaft.

4. Raise the mower to full transport position or until the

driveline just hits the deck at front.

5. If the distance between colored tape and outer shield

tube is 1

9

/

16

” or less, the metal drive tubes

should be shortened per figure A.

6. Shorten the male and female plastic shield tubes

equally. See figure B.

7. The metal drive tubes also have to be shortened in

the same length as the plastic shield tubes. See

figure C.

8. Round off all sharp edges and remove burrs. See

figure D.

9. Apply grease to the metal drive tubes.

10. There should always be a minimum of 1

9

/

16

” clearance

between the male and female drive and shield tubes

when the driveline is operated in its shortest working

position.

11. Lower the mower to the lowest position possible and

check the distance of the colored tape to the end of

the outer shield tube.

12. Driveline tube engagement or overlapping must

always exceed 12”.

13. If tubes do not overlap by 12” or more, consult with

your dealer to obtain a longer driveline.

FRONT GAUGE WHEEL

INTERFERENCE CHECK

Do not operate the mower until this interference check

has been performed. If you use the mower with a differ-

ent tractor, you must perform the check for that particular

mounting again.

1. Raise the mower with the tractor hydraulic system to

the maximum height of lift.

2. Pivot both of the mower front gauge wheels forward

and check that there is clearance between the gauge

wheels and the tractor’s rear tires.

3. If there is interference, lower the mower to the ground

and move hitch to the extended position (see assem-

bly chapter).

4. Move the tractor tires inward to obtain clearance or

lower the mower until clearance exists.

5. Set the 3-point quadrant stop so the mower cannot be

raised beyond the set point. See figure 5.

DRIVELINE LENGTH CHECK

PROCEDURE

OPERATION INSTRUCTIONS (continued)