Dealer Service 27

MAN0670 (11/16/2007)

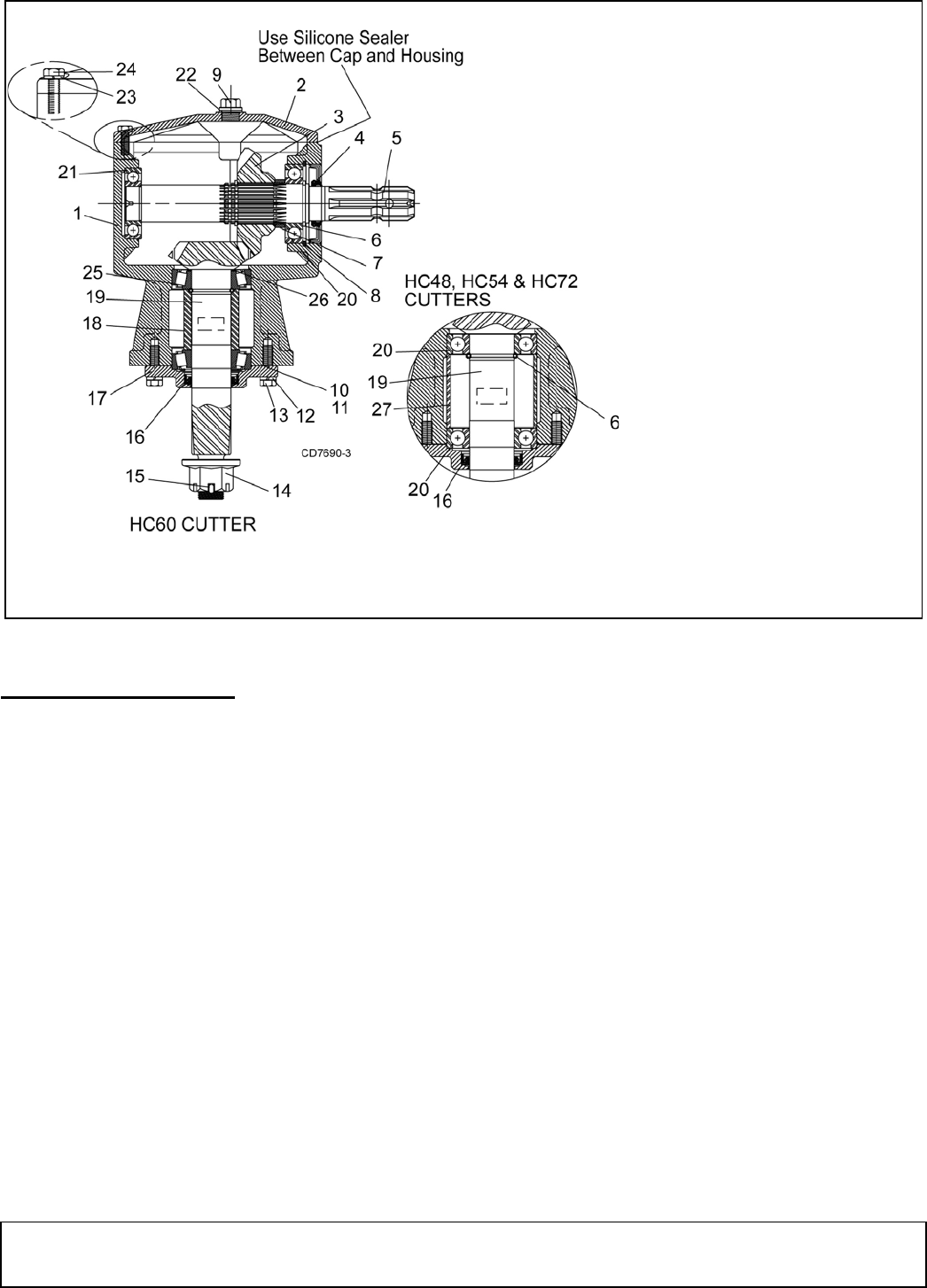

Figure 18. Gearbox Assembly (Cast/Crown Top Gearbox)

CROSSBAR REMOVAL

1. It is necessary to gain access to bottom side of

cutter for crossbar removal. See Blocking

Method, page 18.

NOTE: You will need to use either the puller screw

(Item 6, ) or a small hydraulic jack to remove the

crossbar.

2. To make crossbar removal easier, remove blades.

See Blade Removal, page 19.

3. Remove cotter pin, castle nut, and washer from

bottom of crossbar.

4. Attach a clevis (1) to each end of crossbar, using

blade pins, spacers, keyhole plates, and blade pin

clips. See Figure 19.

5. Position tube assembly (5) with threaded nut

toward crossbar for puller screw removal or down

for hydraulic jack removal.

6. For removal with puller screw, attach tube (5) to

each clevis with bolts (2) and nuts (3). Place pad

(4) in nut and thread puller screw (6) into nut from

bottom. Tighten until pad is solid against gearbox

shaft. For best results, strike head of puller screw

with a hammer while tightening with a wrench.

7. For removal with a jack, attach tube to each clevis

with puller links (7), bolts (2), and nuts (3). Place

jack on tube with end of jack pressing against

gearbox shaft. Slowly apply force with jack.

NOTE: Hydraulic jack will not operate if tipped

more than 90-degrees. Use care to prevent bend-

ing crossbar during removal.

1. Housing

2. Inspection cover

3. 22 Tooth gear

4. Input seal

5. Input shaft

6. Retaining ring

7. Gear spacer

8. Retaining ring

9. M18 x 1.5 Vent plug

10. Output gasket (0.30)

11. Output gasket (0.13)

12. Lock washer

13. M10 x 1.5 x 25 Cap screw

14. 1" - 14 Slotted flange nut

15. Cotter pin

16. Output seal

17. Output cap

18. Output bearing spacer

19. 15 Tooth output shaft & pinion

20. Ball bearing 208

21. Ball bearing 207

22. Sealing washer

23. Lock washer M8

24. M8 x 1.5 x 25 Cap screw

(Rev. 8/29/2011)