46 Assembly

MAN0764 (11/5/2008)

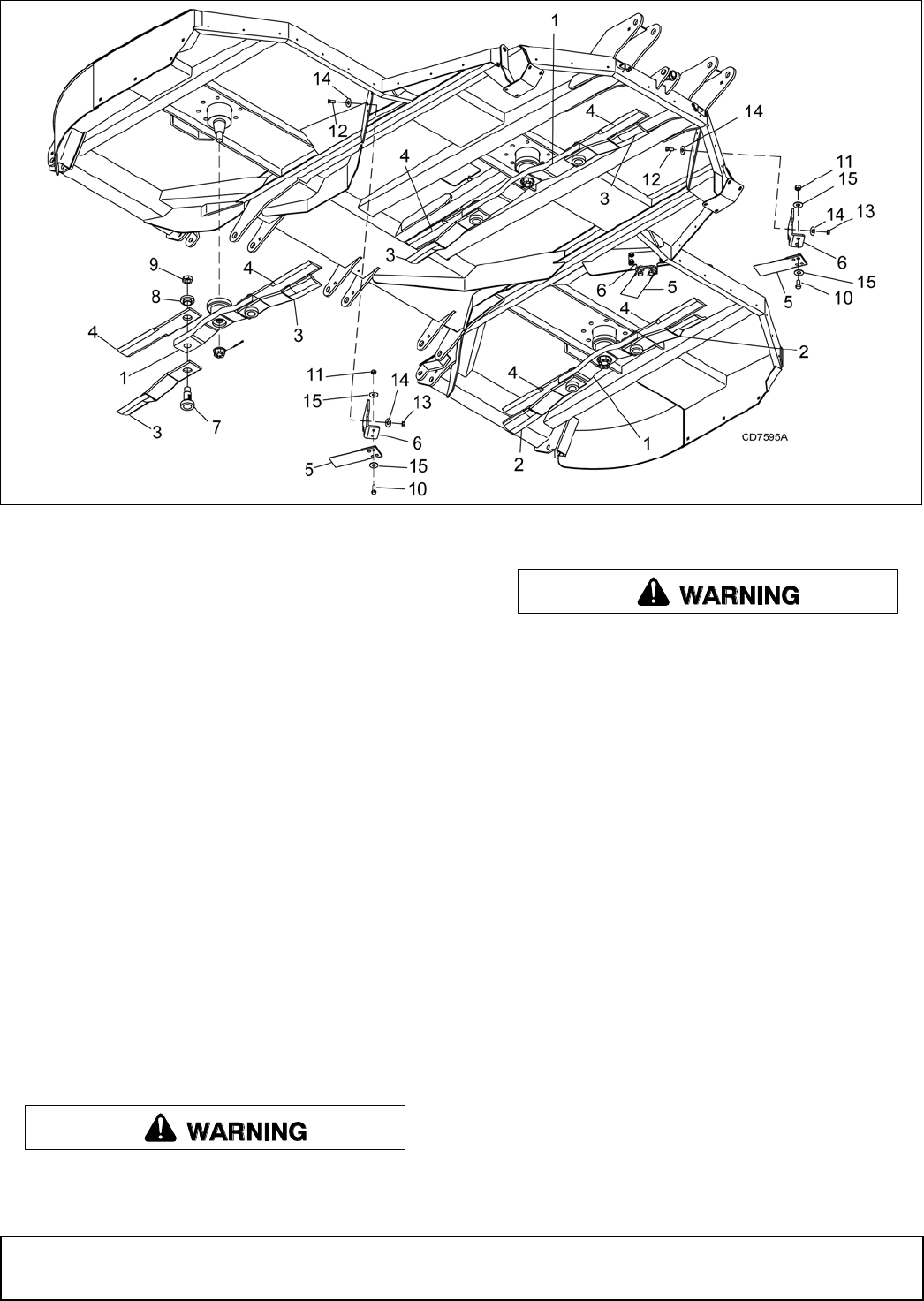

Figure 44. Shredder Kit Installation

1. Attach mounting bracket (6) to the front side of the

front baffle and secure with cap screws (12),

hardened flat washers (14) and lock nuts (13). Do

not tighten hardware.

2. Attach stationary blade (5) to mounting bracket (6)

using two cap screws (10), four hardened flat

washers 915) and lock nuts (11). Blade should be

angled by using the first hole on the left side and

the second hole on the right side. Refer to Figure

43.

3. Rotate crossbar and blades so stationary blade fits

between the two crossbar blades. Adjust mounting

bracket (6) so the stationary blade (5) is 1" below

flat blade (4), Tighten all hardware. See Figure 43.

NOTE: Stationary blade should be parallel to the

rotating blades, point toward the center of the gear-

box and rear of cutter, and overlap rotating blades

approximately 4 inches.

4. Repeat steps to install stationary mounting bracket

(6) and blade (5) to the opposite wing.

BW1620X Counterweight Installation

(Figure 45)

The offset model is unstable without adequate

counterweight. Use counterweight box loaded with

1300 lbs (591 kg) of steel.

■ Use a suitable lifting device of sufficient capac-

ity. Use adequate personnel to handle heavy com-

ponenets.

This unit may be operated with only one wing - either

right or left. With only one wing, the unit is unshielded

and unstable. When electing to operate with one wing,

you must install a counterweight box, available from

your dealer. This box has a dual purpose: it substitutes

for the shielding and for the weight of the removed

wing.

The counterweight must be installed in the following

sequence and will require at least two people. A floor

jack or a suitable lifting device will be helpful to align

the hinges when installing the hinge pin.

1. Remove hinge pin (2) from center section.

2. Align skid shoe (3) with holes on bottom and inside

of weight box (6). Secure bottom with the hardware

provided with skid shoe.

3. Place weight box assembly adjacent to the center

section and align hinge sections.

4. Insert hinge pin through the hinge sections. Secure

hinge pin with two washers (10) and two spring

pins (9).

(Rev. 2/6/2009)