Assembly 31

MAN0680 (11/30/2007)

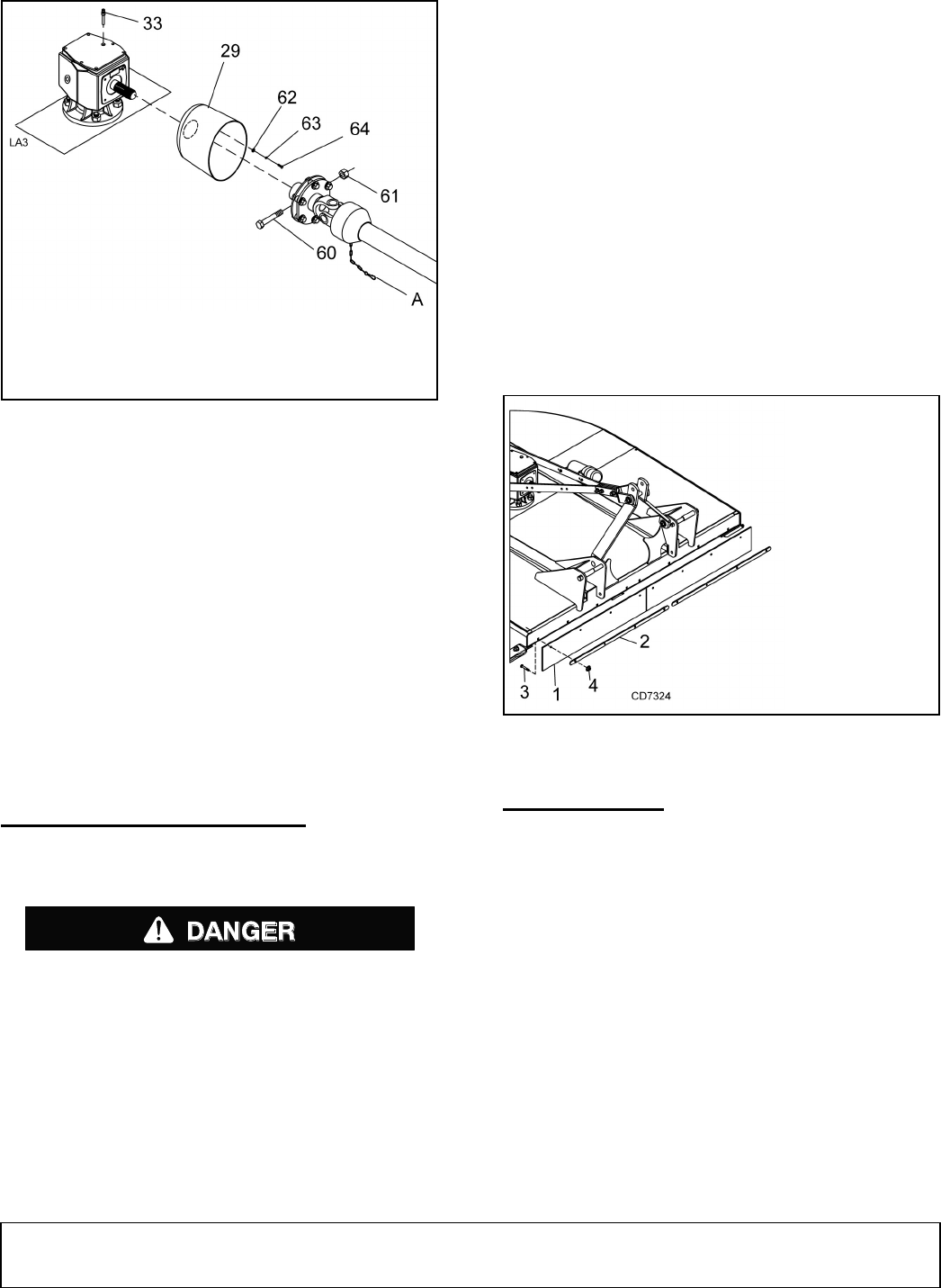

Install Slip Clutch Driveline

Figure 32. Slip Clutch Driveline Assembly

A new slip clutch, or one that has been in storage over

the winter, may seize.

NOTICE

■ A grade 8.8 metric bolt must be used to attach

clutch driveline to gearbox.

1. Before operating slip clutch, make sure it will slip.

Refer to SLIP CLUTCH ADJUSTMENT, page 18.

2. Place the shield (29) against gearbox and secure

using four cap screws (64), lock washers (63) and

flat washers (62). Torque bolts (64) to 12 lbs-ft.

3. Install driveline onto gearbox input shaft and

secure with bolts (1) and nuts (2).

INSTALL SAFETY SHIELDING

Install Optional Chain Shielding

Full chain, rubber, or steel band shielding must

be installed when operating in populated areas or

other areas where thrown objects could injure peo-

ple or damage property.

• If this machine is not equipped with full chain,

rubber, or steel band shielding, operation must

be stopped when anyone comes within 300 feet

(92 m).

• This shielding is designed to reduce the risk

of thrown objects. The mower deck and protec-

tive devices cannot prevent all objects from

escaping the blade enclosure in every mowing

condition.

It is possible for objects to ricochet

and escape, traveling as much as 300 feet (92 m).

The optional chain shielding assemblies are ready for

installation when you receive them.

1. Refer to Front & Rear Chain Shielding, page 42

and attach as shown by inserting the bolts from

inside the cutter frame out through the shielding.

2. Install hardware as shown in the parts drawing.

Install Rubber Deflector

1. Attach rubber deflector (1) and link (2) to front of

cutter using carriage bolts (3) and flange lock nuts

(4).

2. Insert bolts from inside the cutter frame out through

the shielding.

Figure 33. Rubber Deflector Installation

FILL GEARBOX

NOTICE

■ Gearbox is not filled at the factory. Prior to

delivery to customer, make sure gearbox is filled

only half-full with 80W or 90W API GL-4 or GL-5

gear lube. Use side hole to remove any excess oil.

1. Remove vent plug/dipperstick (9) on top of gearbox

and plug on side of gearbox. Use 5/16" allen

wrench to remove plug.

2. Make sure vent plug hole is clear.

3. Fill gearbox until oil runs out the side hole on

gearbox. Use a high quality gear oil with a viscosity

index of 80W or 90W and an API service rating of

GL-4 or GL-5.

4. Install side plug and vent plug.

A. Anti-rotation chain

29. Clutch shield

33. Vent plug/Dipperstick

60. 12 mm x 1.5P x 65 mm

Cap screw GR8.8

61. 12 mm x 1.5P Hex lock nut

62. 5/16 Flat washer

63. 5/16 Lock washer

64. M8 x 1.25P x 20 mm HHCS

1. Rubber deflector

2. Link

3. 3/8 NC 1 Carriage bolt

4. 3/8 NC Flange lock nut