-- 5 --

S

To reduce the risk of hearing loss

associated with sound level(s), hearing

protection is required.

S

To reduce the r isk of injury associated with

contacting rotating parts, s top the engine be-

fore installing or r e m o v in g attac h ments. D o

not oper ate without guard( s) in place.

S

Operate power equi pmentonly atreasonable

hours--not earlyin the morning orlate at night

whenpeople m ightbe di sturbed.Complywith

times listedin localordinances. Usualrecom-

mendations are 9:00 a .m. to 5:00 p.m.,

Monday though Saturday.

S

To reduce noise levels, limit the number of

pieces of equipment used at any one time.

S

To reduce noise levels, operate power

blowers at the lowest possible throttle

speed to do the job.

S

Use r akes andbrooms to loosen debris be-

fore blowing.

S

In dusty conditions, slightly dampen sur-

faces or use amister attachment when wa-

ter is available.

S

Conserve water by using power blow er s

instead of hoses for many lawn and garden

applications, including areas such asgutters,

screens, patios, grills, por ches, and gardens.

S

Watchout f orchildren, pets, openwindows,

or freshly washed cars. Blow debris away

safely.

S

Use the full blower nozzle extension so the

air stream can work close to the ground.

S

After using blowers and other equipment,

CLEAN UP! Dispose of debris in trash re-

ceptacles.

FUELING

WARNING:

Remove fuel cap slowly

when refueling.

This engine is certified to operate on

unleaded gasoline. Gasoline must be mixed

with agood quality 2--cycle air--cooled engine

oil designed to be mixed at a ratio of 40:1.

Poulan/Weed Eater brand oil is

recommended. (A 40:1 ratio is obtained by

mixing 3.2 ounces of oil with 1 gallon of

unleaded gasoline). When mixing fuel follow

the instructions printed on the container.

Always read andfollow thesafety rules under

HANDLE FUEL WITH CAUTION.

IMPORTANT

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or

methanol) canattract moisture which leads to

separation and formation of acids during

storage. Acidic gas can damage the fuel

systemofanengine while instorage. Toavoid

engine problems, empty the fuel system

before storage for30days orlonger. Drainthe

gastank, start theengine andlet itrununtil the

fuel lines andcarburetor are empty. Usefresh

fuel next season. Nev er use engine or

carburetor cleaner products in the fuel tank or

permanent damage may occur .

STARTING

TO STOP THE ENGINE

D

To stop the engine, move the throttle lever

to the STOP position.

BEFORE STARTING THE ENGINE

D

Fuel engine. Move at least 10 feet (3 me-

ters) away from the fueling site.

D

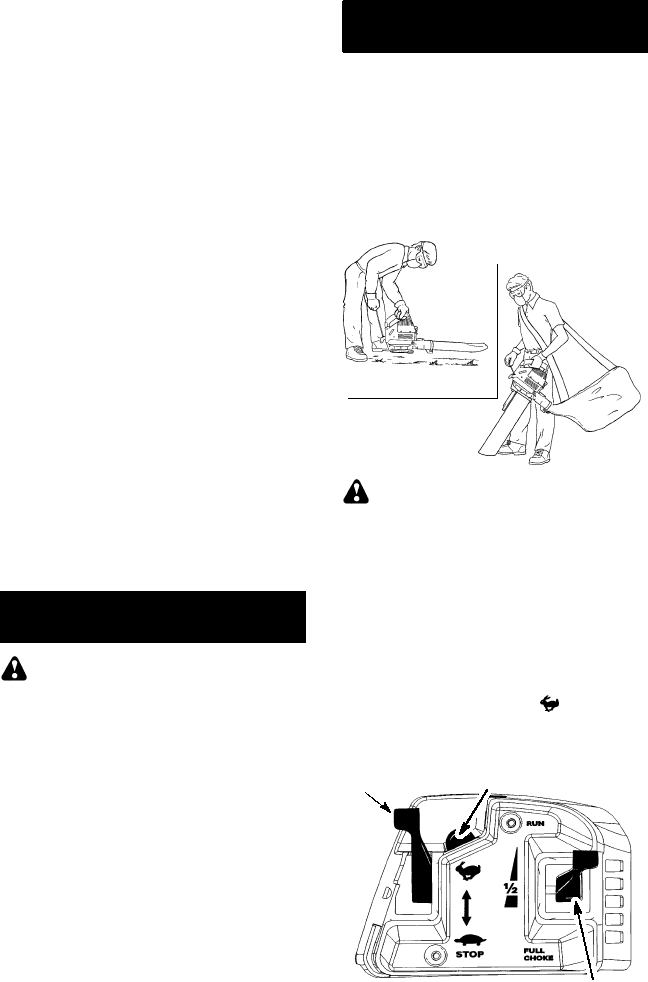

Hold the unit in the starting position as

shown. Make sure the blower end is di-

rected away from people, animals, glass,

and solid objects.

Blower

Vacuum

STARTING POSITION

WARNING:

When starting engi ne,

holdtheunit asillustra te d.Don otsetunitonany

surfaceexcept a clean, hardarea w henstarting

engine or while engine is running. Debris such

as gr avel, s and, dust, gr ass, etc. coul d be

picked up by the air intake and thrown out

through the discharge opening, damaging the

unit or property, or causing ser ious injury to by-

standers or the operator.

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

S

Move throttle lever to the

position.

S

Move choke lever to the FULL CHOKE

position.

S

Slowly press the primer button 8 times.

Throttle Lever

Choke Lever

Primer Button

S

Pull starter rope sharply until engine at-

tempts to run, but no more than 5 pulls (be-

low 30

_

F, 8 pulls).

NOTE:

If engine attempts to start before the

5

th

pull, go to next step immediately.

S

Move the choke lever to the HALF CHOKE

position.