Maintenance Instructions CLEANING

52

4. Use a bright light inside the element to inspect

for damage. Check the element very carefully

for pin holes or other damage that will allow

dirt to leak through the paper media. Replace

element if necessary.

5. Check the condition and resilience of the radial

sealing surface (inside of the open end) of the

filter. Replace the filter if any cracks, tears, or

other damage to the sealing surface are noted.

6. Use a clean, damp cloth and wipe the interior of

the air cleaner canister clean. Use special care

to clean both the inside and outside surfaces

of the outlet tube.

IMPORTANT: Any dust left on the inside of the

outlet tube will go into the engine and cause

wear.

7. Check the outside surface of the outlet tube for

smoothness and cleanness (this is the sealing

surface).

8. Insert and seat the filter element carefully into

the canister, applying pressure at the outer rim

of the filter; not at the flexible center. Make sure

the filter element is completely in place before

installing the cover.

IMPORTANT: DO NOT use the cover latches

to force the filter into the canister -- the cover

should fit on with no extra force.

NOTE: DO NOT use petroleum based lubri-

cants on the sealing surfaces of the filter; use tal-

cum powder or dry silicone lubricants if required

for filter installation.

Air Filter Element Replacement

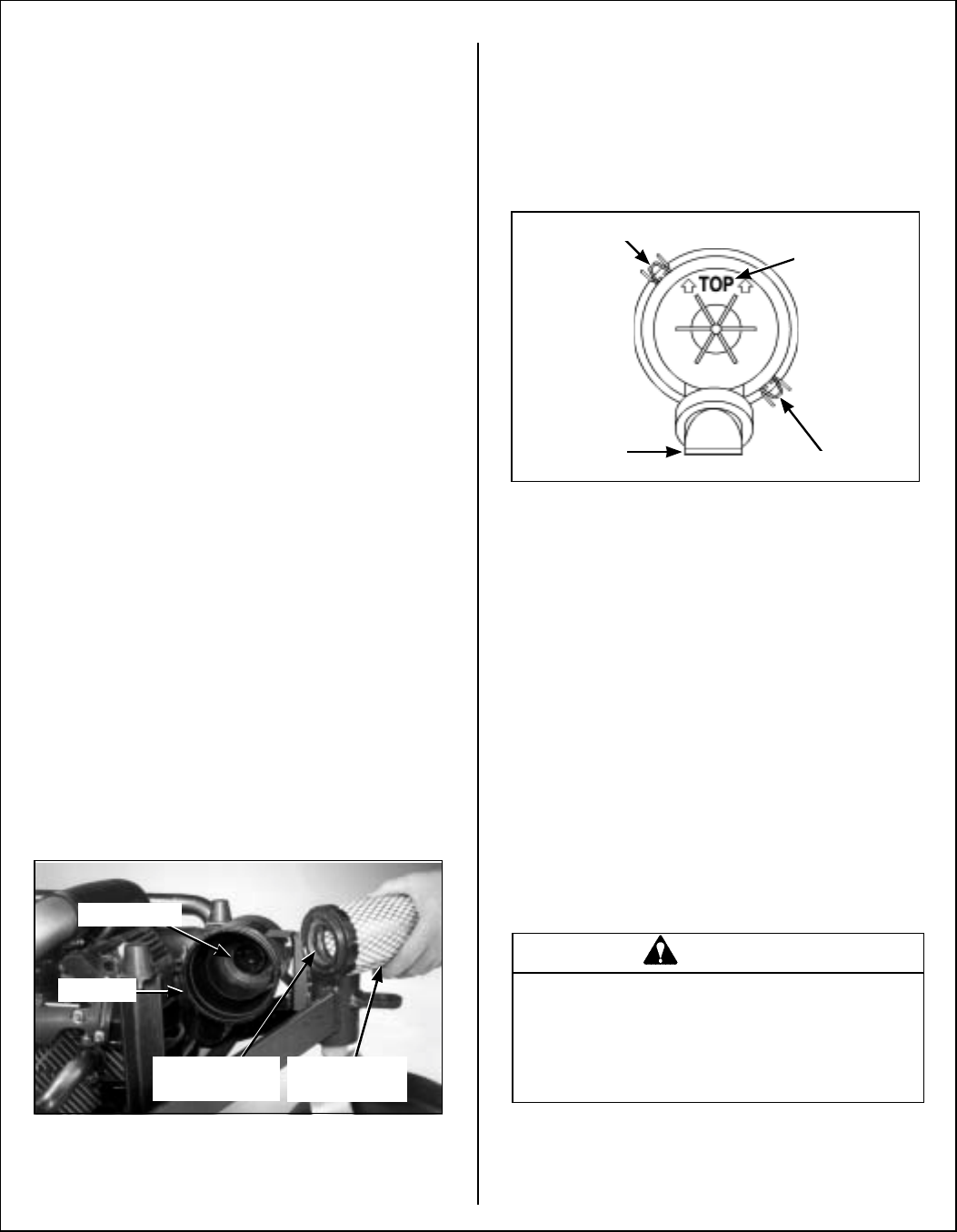

9. Install the cover with the word “TOP” properly

oriented to the top of the canister. Give the cov-

er a slight twist as it reaches the canister to

make sure the tab inside the cover goes into a

slot, otherwise the cover will not fit properly.

Make sure both the top and bottom cover latch-

es are securing the cover in place.

Proper Orientation of Air Cleaner Cover

10. Check the air intake hose for cuts, nicks, etc.,

and the hose clamps for tightness.

11. Reset the air restriction indicator (press button

on bottom).

Engine Cooling System

Air Intake System

To prevent engine overheating and possible engine

damage, clean grass clippings, chaff, and dirt from

the rotating engine air intake screen after every 8

hours of operation. In certain mowing conditions

(dry grass, leaves, tree “cotton”, etc.), it may be nec-

essary to check and clean the screen several times

each day to prevent engine overheating.

Radial Sealing

Surface

Radialseal™

Filter Element

Outlet Tube

Canister

CAUTION

Operating the engine with a blocked air

intake screen, dirty or plugged cooling

fins, and/or cooling shrouds removed will

cause engine damage from overheating.

Cover Latch

Vacuator™

Valve

Cover Latch

Orient to Top

of Canister