10

4.6 PUMP

When using the pump scrupulously observe the instructions in the enclosed

handbook supplied by the manufacturer.

The pump can be identified by the ratings plate on the same; the main data on

the pressure and delivery are easy to find on this plate.

Normally the pumps mustn’t exceed 550 RPM; a higher speed won’t improve

performance but there is a risk of compromising the life and safety of the pump.

There is a safety valve on the pump, calibrated to prevent overpressure. Don’t

tamper with this valve for any reason and don’t block or obstruct the pipes

connected to it in any way.

4.7 SUCTION FILTER

The sprayer is fitted with a suction filter with filter cartridges that have roughly a

50-gauge mesh, which is equivalent to a hole of 0.4 at 0.35 mm.

An efficient filter lets the sprayer work properly.

You should periodically check that the filter cartridge is clean, this check should

be done more often if there are impurities in the liquid.

To inspect the filter cartridge wear rubber acid-proof gloves as the liquid in the

filter can come into contact with your hands when you open the filter.

Don’t perform this operation with the pump running as the depression produced

blocks the cover preventing the removal.

Before removing the cover of the filter, make sure that the same is isolated from

the tubing by unscrewing the relevant rear valve (FIG. N° 3).

After washing the cartridge, reassemble the cover making sure you connect the

same to the circuit again, using the valves described above in the opposite order.

WARNING!: Don’t disperse the washing residues in the environment!!

4.8 PRESSURE REGULATOR

To use the pressure regulator, follow the instructions in the enclosed handbook

scrupulously. The pressure regulator controls all of the most important spraying

functions, the thorough knowledge of its functions makes work easier and more

precise.

The working pressure and the maximum pressure of the sprayer are determined

by the pressure regulator which also protects the circuit from overpressure in any

work conditions. (In serious but very rare cases, if the connecting pipes get

blocked the pressure relief valve lets the pressure off)

In some setups there may be a pump that can reach a pressure of 50 bar

controlled by a regulator designed for 20 bar. In this case the maximum pressure

that can be reached is 20 bar.

The regulators can be manual, mounted on the sprayer or at a distance to make

the controls easier to use; or electrical with a control panel in the cabin.

There are also regulator versions with mechanical remote controls with a cable. If

the tractor has a waterproof cabin the use of electrical controls is obligatory.

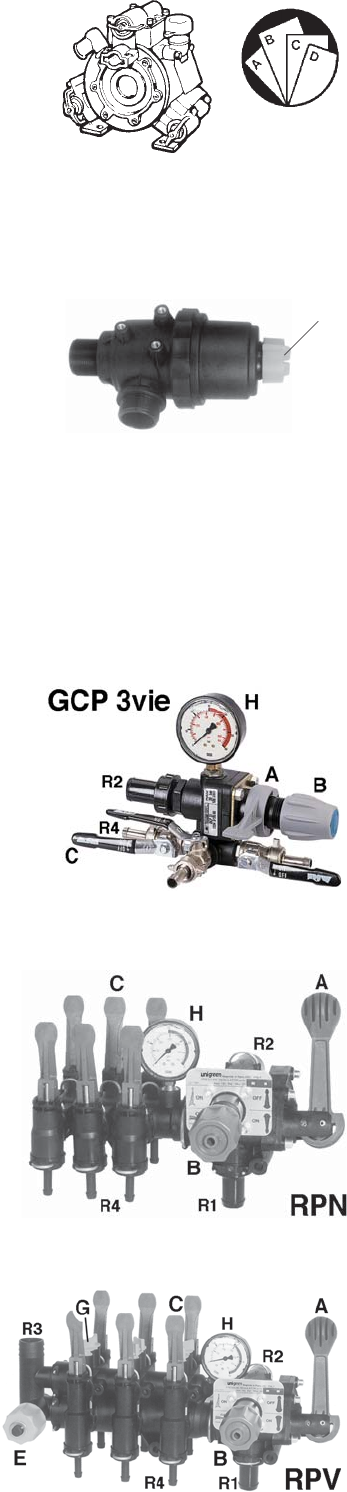

4.8.1 COMPONENTS OF THE PRESSURE REGULATOR

Below you will find the indications for the main models fitted on Unigreen

products.

A main ON-OFF command: “open” lets the fluid flow into the circuit in use;

“closed” empties the tank.

B maximum pressure valve: adjusted by hand with the relevant knob (drains the

excess liquid when the set pressure is reached).

C boom section tap: opens the corresponding boom or drains to the

compensation regulator (G).

D auxiliary tap: can be used for various accessories (it is always manual).

E volumetric pressure valve (proportional):

(when present) it regulates the spraying pressure. The valve automatically

compensates variations in speed (within the scope of the same gear ratio),

keeping the quantity of liquid supplied per surface unit (litres/hectare) unchanged.

F self-cleaning filter: filters the delivery liquid.

G compensation regulators: suitably regulated, these make it possible to keep

the pressure constant when one or more sections of jets is closed, they don’t

influence treatments with the boom fully open.

H manometer: indicates the working pressure.

Connections:

R1 supply union

R2 drain union

R3 volumetric drain union

R4 boom section delivery union

FIG. 3

Valve