Maintenance & Adjustments

6

Maintenance Schedule

Before

Each use

Every

10 Hours

Every

25 Hours

Every

50 Hours

Every

100 Hours

Prior

to Storing

Check Engine Intake Screen/Cover

P

Clean Battery Terminals

P P

Lube Front Pivot Axle and Caster Axles

P P

Clean Engine Cooling Fins

P P

Lube Deck Wheels

P P

Maintenance

Before performing any maintenance or

levers fully outward in the neutral position, engage

the parking brake, stop the engine and remove the

key to prevent unintended starting.

Engine

intervals, procedures, specifications and instructions.

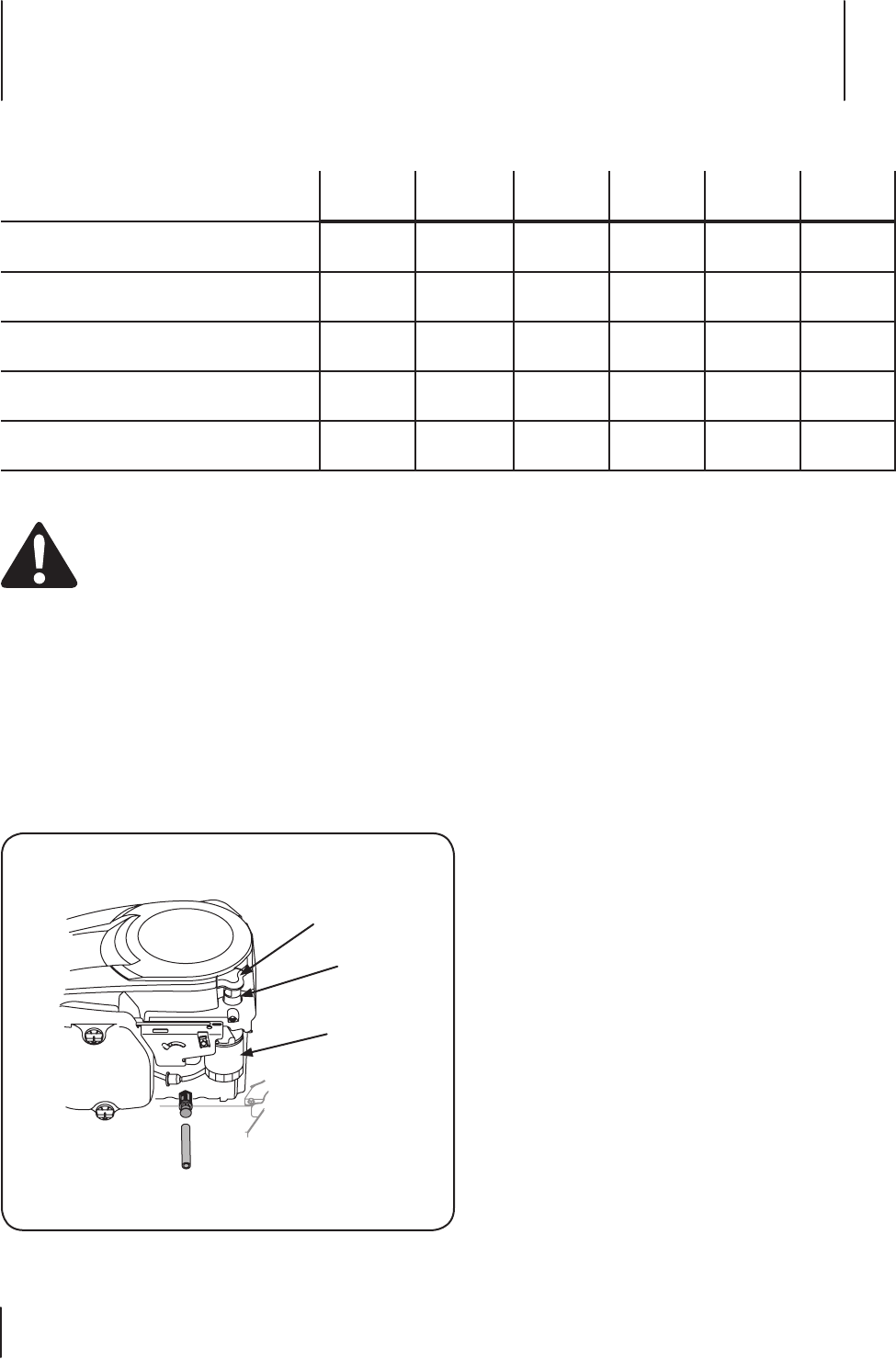

Draining the Engine Oil

Locate the oil drain port on the left side of the engine.

2.

the oil fill cap/dipstick from the oil fill tube.

3.

oil drain port. Route the opposite end of the hose into an

appropriate oil collection container with at least a 2.0 quart

capacity, to collect the used oil.

Turn the oil drain valve ⁄-turn, then pull outward to begin

draining oil. After the oil has finished draining, push the

end of the oil drain valve back in and turn ⁄turn to secure

it back in place Re-cap the end of the oil drain valve to

keep debris from entering the drain port.

After the oil has finished draining, push the end of the oil

drain valve back in, until the tabs click into place. Re-cap

the end of the oil drain valve to keep debris from entering

for refilling instructions, oil type and amount.

NOTE: Maintenance, repair, or replacement of the emission control

be performed by any engine repair establishment or individual.

Warranty repairs must be performed by a Troy-Bilt Dealer.

Hydrostatic Transmission

The zero turn tractor is equipped with dual integrated

hydrostatic pumps/transaxles that are sealed and are

maintenance-free. Fluid levels cannot be checked and fluid

cannot be added or changed.