13

5

WARNING

IMPORTANT

Never hit the engine

shaft in any manner,

as a blow will cause

permanent damage to

the engine.

Maintaining

Your Log

Splitter

Hydraulic Fluid and Inlet Filter

• Check the hydraulic fluid level in the log splitter

reservoir tank before each use. Maintain fluid level

within the range specified on the dipstick at all times.

• Change the hydraulic fluid in the reservoir every 100

hours of operation. Follow the steps below:

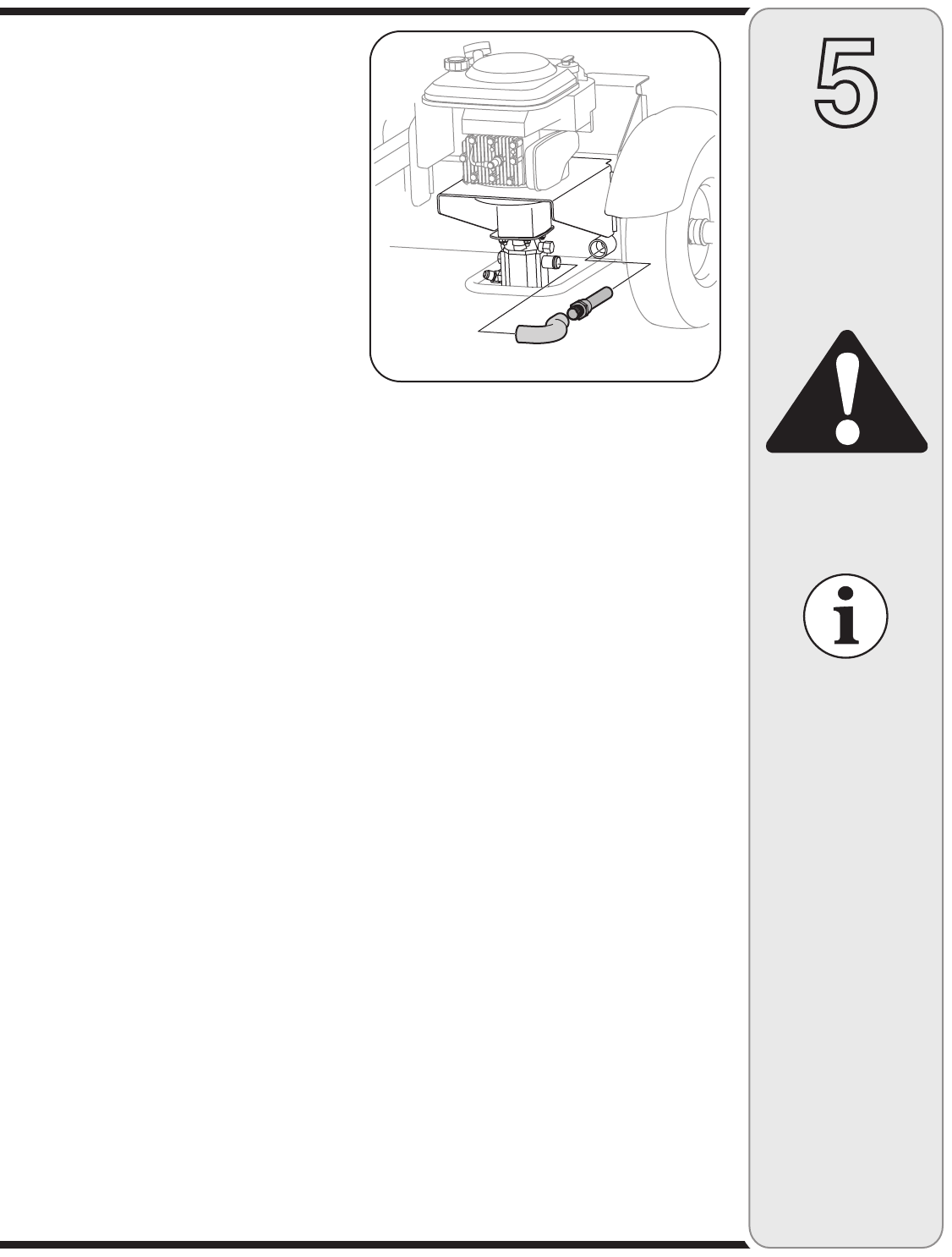

1. Disconnect the suction hose from the bottom of the

reservoir tank.

2. Carefully unthread the inlet filter and clean it with

penetrating oil. See Figure 5-2.

3. Allow the fluid to drain into a suitable container.

4. Reinsert the filter and refill the reservoir with three (3)

gallons of oil. Approved fluids include Dexron® III /

Mercon® III automatic transmission fluid, a 10 Weight

AW hydraulic oil or Pro-Mix™ AW-32 Hydraulic Oil.

• Maintain fluid level within the range specified on the

dipstick at all times. When checking the fluid, always

make sure to tighten the dipstick until the top of the

threads are flush with the top of the pipe.

NOTE: Always dispose of used hydraulic fluid and engine

oil at approved recycling centers only.

• Contaminants in fluid may damage the hydraulic

components. Flushing the reservoir tank and hoses

with kerosene whenever service is performed on

the tank, hydraulic pump or valve is recommended.

Contact an authorized service dealer.

Hydraulic Filter

• Change the hydraulic filter every 50 hours of opera-

tion. Use only a 10 micron hydraulic filter. Order part

number 723-0405.

Beam and Splitting Wedge

• Lubricate both sides of the beam (where it comes into

contact with the splitting wedge), before each use,

with engine oil. The wedge plate on the log splitter is

designed so the gibs on the side of the wedge plate

can be removed and rotated and/or turned over for

even wear.

• Make certain to readjust the adjustment bolts so

wedge moves freely, but no excess space exists

between the wedge plate and the beam.

Hose Clamps

• Check, before each use, if hose clamps on the

suction hose (attached to the side of the pump) are

tight. Check the hose clamps on the return hose at

least once a season.

Engine

Refer to the separate engine manual for all maintenance

instructions.

Flexible Pump Coupler

The flexible pump coupler is a nylon “spider” insert,

located between the pump and the engine shaft. Over

time, the coupler will harden and deteriorate.

Replace the coupler if you detect vibration or noise

coming from the area between the engine and the

pump. If the coupler fails completely, you will experience

a loss of power.

Figure 5-2

NOTE: Always dispose

of used hydraulic

fluid and engine oil at

approved recycling

centers only.