Section 5: Maintenance 13

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to

a stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key on electric

start models.

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

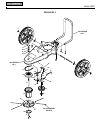

10. Reattach the idler arm spring (R,

Figure 5-6) in the hole in the idler arm (T).

11. A new belt may need to be adjusted

by following the “Adjusting Trimmer

Head Engagement” instructions in this

Section.

TRIMMER/MOWER CLEANING

AND DEBRIS REMOVAL

Thorough and regular cleaning of debris

from the engine and the machine is re-

quired for maximum efficiency and good

overall performance. Inspect and clean

the following areas regularly, making

sure the engine is stopped, and cool, be-

fore proceeding:

• Brush and wipe off all engine surfaces,

especially before checking oil or adding

fuel. Do not let debris, oil or grease ac-

cumulate. To access the front of the

engine, lift the debris shield up and tilt it

forward.

• Wipe the deck clean, particularly near

the engine muffler.

• Clean the underside of the deck.

• Keep safety and operating decals clean

and legible.

• Keep all operating control levers

debris-free so they work properly.

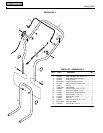

CLEANING THE ENGINE

Before each use of the machine and at

each refueling, clean grass, chaff or accu-

mulated debris from the finger guard area

on top of the engine (see Figure 5-7), and

from the linkage, springs and controls on

the engine. Keep the area around and be-

hind the muffler free of any combustible

debris. See “Cleaning Debris” in the

engine manual for complete cleaning in-

structions. Do not use water to clean

engine parts as water could contaminate

the fuel system. Use a brush or dry

cloth. Be sure engine is cool before

cleaning around muffler area.

NOTE: The separate engine air cleaner

must also be serviced according to the

instructions in the engine manual.

LUBRICATION

Applying light oil or a silicone-based lu-

bricant to your machine allows parts to

work more smoothly and protects them

from the elements. Use Silicone-base

Spray Lubricant (or light oil) to lubricate

the following parts:

• Throttle control cable

• Control bail cable

• Nuts, bolts and other hardware

NOTE: The spindle head is permanently

lubricated at the factory. There is no

need for additional lubrication.

COMPACT STORAGE

For compact storage of the unit, remove

the two screws and locknuts securing the

handlebar and carefully (to avoid kinking

the cables) rotate the handlebar so that

the upper portion rests on the engine and

the handlebar legs face to the rear of the

unit.

GENERAL ENGINE MAINTENANCE

Perform the following engine mainte-

nance for your engine according to the

engine maintenance schedule and in-

structions in the separate engine manual:

Engine Oil Service

Check the engine oil level before starting

the engine each day and check it after

each 5 hours of continuous operation.

Running the engine when it is low on oil

will quickly ruin the engine.

Change the oil after every 25 hours of op-

eration and even sooner when operating

in extremely dirty or dusty conditions.

Air Cleaner Service

Operating the engine with a dirty, clogged

air filter can cause poor performance and

damage to the engine. Inspect and ser-

vice the air cleaner after every 25 operat-

ing hours, more often if operating in very

dusty or dirty conditions. Never operate

the engine without the air cleaner

installed.

Figure 5-6A

Figure 5-7

Engine parts must be kept clean to re-

duce the risk of overheating and ignition

of accumulated debris. This is espe-

cially important if cutting tall grass.

Clean accumulated debris at each refu-

eling and before each use of machine.

Failure to comply can cause injury or

property damage.

WARNING

Finger Guard