7

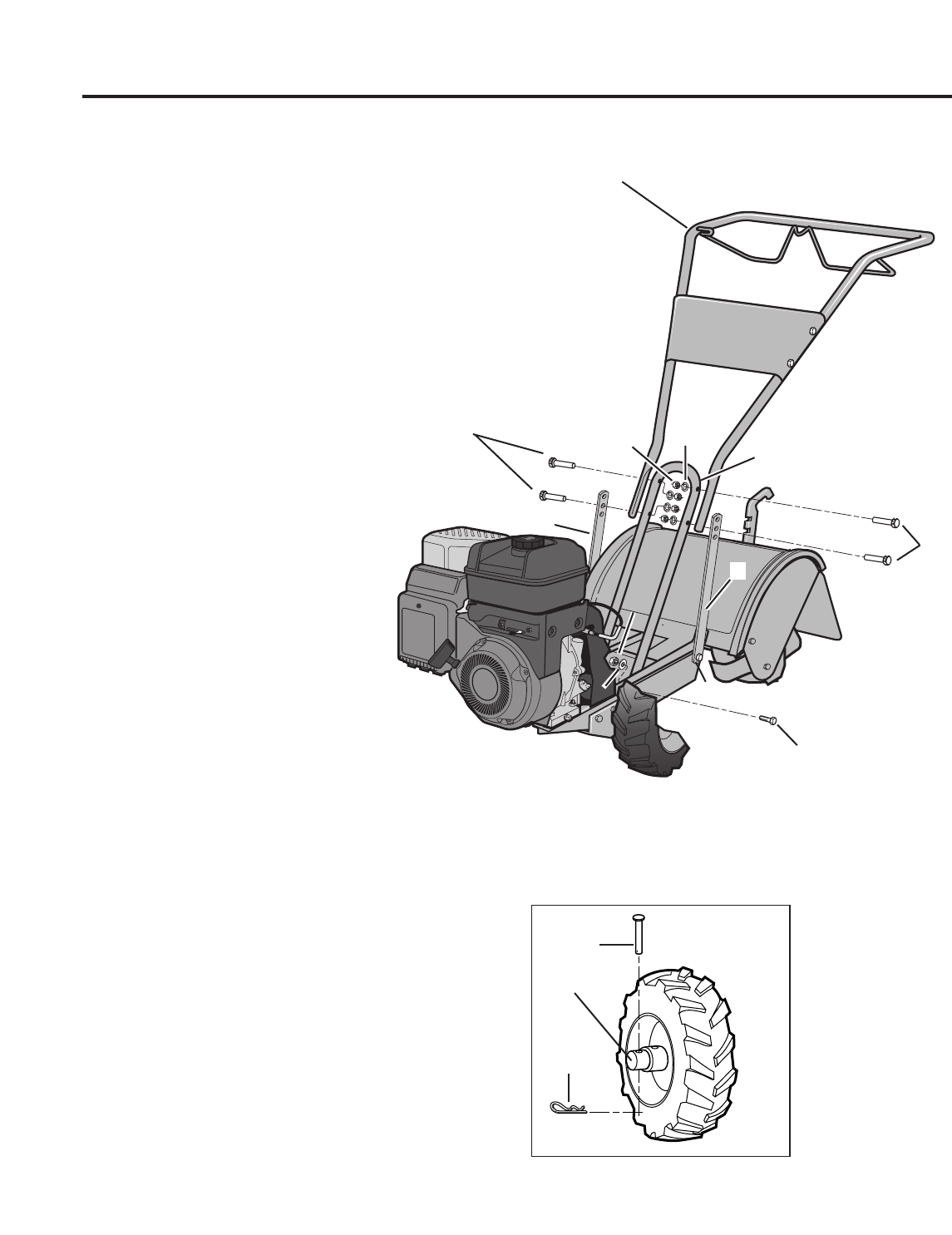

Section 2: Assembly

STEP 2: Attach Handlebar

1. Attach the two legs of the handlebar

support (A, Fig. 2-2) loosely to the inner

sides of the tiller frame using two 3/8"-16

x 3/4" hex hd. screws (B), two 3/8” flat

washers (C) and 3/8"-16 hex locknuts (D).

2. Using using two 5/16"-18 x 1-1/2" hex

hd. screws (G), 5/16" split lockwashers

(H) and 5/16"-18 hex nuts (I), loosely

attach the the handlebar support (A) using

the upper holes.

3. There are three height adjustment holes

in the two handlebar support brackets. E

& F, Fig. 2-2). Use a setting that will

position the handlebars at approximately

waist level when the tines are 3”-4” into

the soil. Loosely attach the handlebar

support brackets

to the outside of the

handlebar assembly (K) using two 5/16"-

18 x 1-1/2" screws (G), 5/16" split lock-

washers (H) and 5/16"-18 hex nuts (I).

NOTE: If a support bracket will not move,

loosen attaching screw (J) and nut.

IMPORTANT: The support brackets must

be assembled

to the outside of the

handlebar assembly.

4. Tighten all handlebar mounting

hardware securely.

STEP 3: Move Tiller Off Shipping

Platform

To move the tiller without the engine

running, put the wheels in their

FREEWHEEL position, as described below.

1. Use a sturdy block to raise one wheel

off the ground.

2. Remove the hairpin cotter (L, Fig. 2-3)

and wheel drive pin (M). Slide the wheel

inward on the wheel shaft (N). Reinstall

the wheel drive pin and hairpin cotter

through the wheel shaft only (not through

the wheel hub). Repeat with the other

wheel.

3. Using the handlebar as a lever, roll the

tiller to a flat area.

IMPORTANT: Before starting the engine,

the wheels must be placed in their WHEEL

DRIVE position (pins through wheel hubs

and wheel shaft). This procedure is

described in “Wheel Drive Pins” in

Fig. 2-2: Attach handlebar.

G

H

A

F

E

I

B

C

G

K

J

D

Fig. 2-3: Wheel in FREEWHEELING

position (wheel drive pin through wheel

shaft only).

M

N

L