22

Clutch Bail all the way up to the bottom of

the upper handlebars, you will need to

loosen the belt tension.

Also check the belt for cracks, cuts or

frayed edges and replace it as soon as

possible.

• Check belt tension after the first two

hours of initial operation (new belt).

• Check belt tension after every 10

operating hours.

To Check Forward Belt Tension:

1. Be sure that the engine is stopped and

the spark plug wire is disconnected and

moved away from the spark plug.

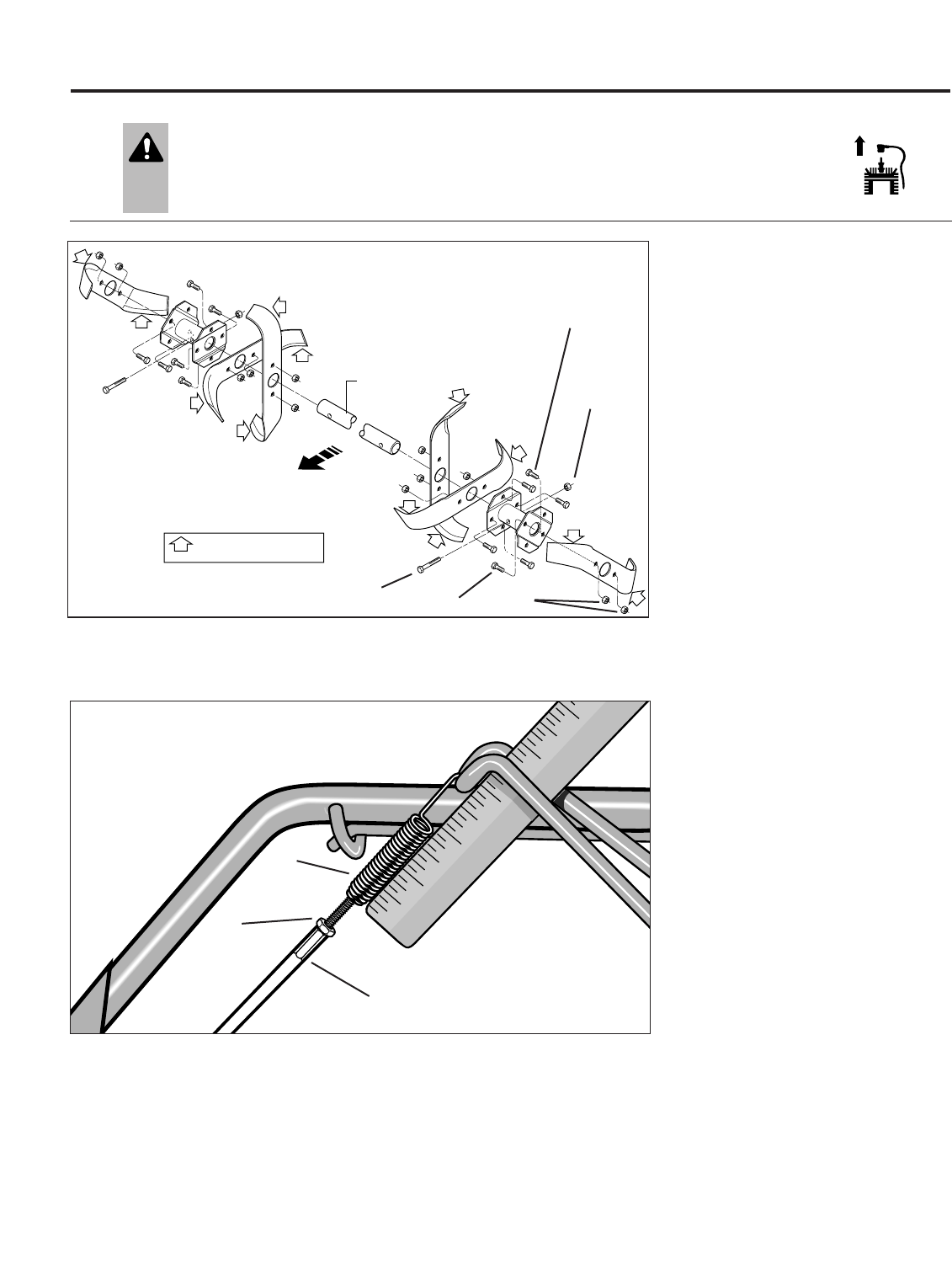

2. Loosen nut “C” (Figure 5-4) several

turns so it is about halfway up the

threaded adjustment screw.

3. Lift the Forward Clutch Bail up and

hold it to the bottom of the handlebars.

Measure the length of the clutch bail

spring (A, Figure 5-4) with a ruler. If the

belt tension is correct, the length of the

coiled portion of the spring should be

approximately 1-7/8". Nut “C” should

then be snugged down against the top of

the adjuster (B).

4. If the spring is too short, the belt

tension will be too loose. If the spring is

too long, the belt tension will be too tight.

5. To adjust the length of the spring,

release the Forward Clutch Bail. Thread

the hex nut (C, Fig. 5-4) halfway up the

adjustment screw. Turn the screw inside

the spring (A, Figure 5-4) counterclock-

wise (as viewed from the operator’s

position) while holding the adjuster (B)

steady to increase the length of the

spring, or turn clockwise (as viewed from

the operator’s position) to decrease the

length of the spring.

NOTE: If you have difficulty holding the

adjuster steady by hand, use a pliers or

wrench on the adjuster. While you turn

the screw, keep the Forward Clutch Cable

Figure 5-3: Tines, tine holders and installation hardware.

Section 5: Maintenance

WARNING Before inspecting, cleaning or servicing the unit, shut off engine, wait for all

parts to come to a complete stop, disconnect spark plug wire and move wire away from spark

plug. Failure to follow these instructions can result in serious personal injury or

property damage.

ENGINE

TINE

SHAFT

DENOTES CUTTING EDGE

OF TINE

A

D

C

C

Figure 5-4: Lift bail and check length of Clutch Bail Spring to check for correct belt tension

(1-7/8").

1

2

3

4

5

A

C

B

B

OPERATOR

POSITION

CHECKING AND ADJUSTING

FORWARD DRIVE BELT TENSION

Maintaining correct tension on the

forward drive belt is important to good

tilling performance and long belt life. A

loose belt will slip on the engine and

transmission pulleys and cause the tines

and wheels to slow down – or stop com-

pletely – even though the engine is

running at full speed. A loose belt can

also result in premature belt wear.

If you find you can not bring the Forward