Maintenance (continued)

23

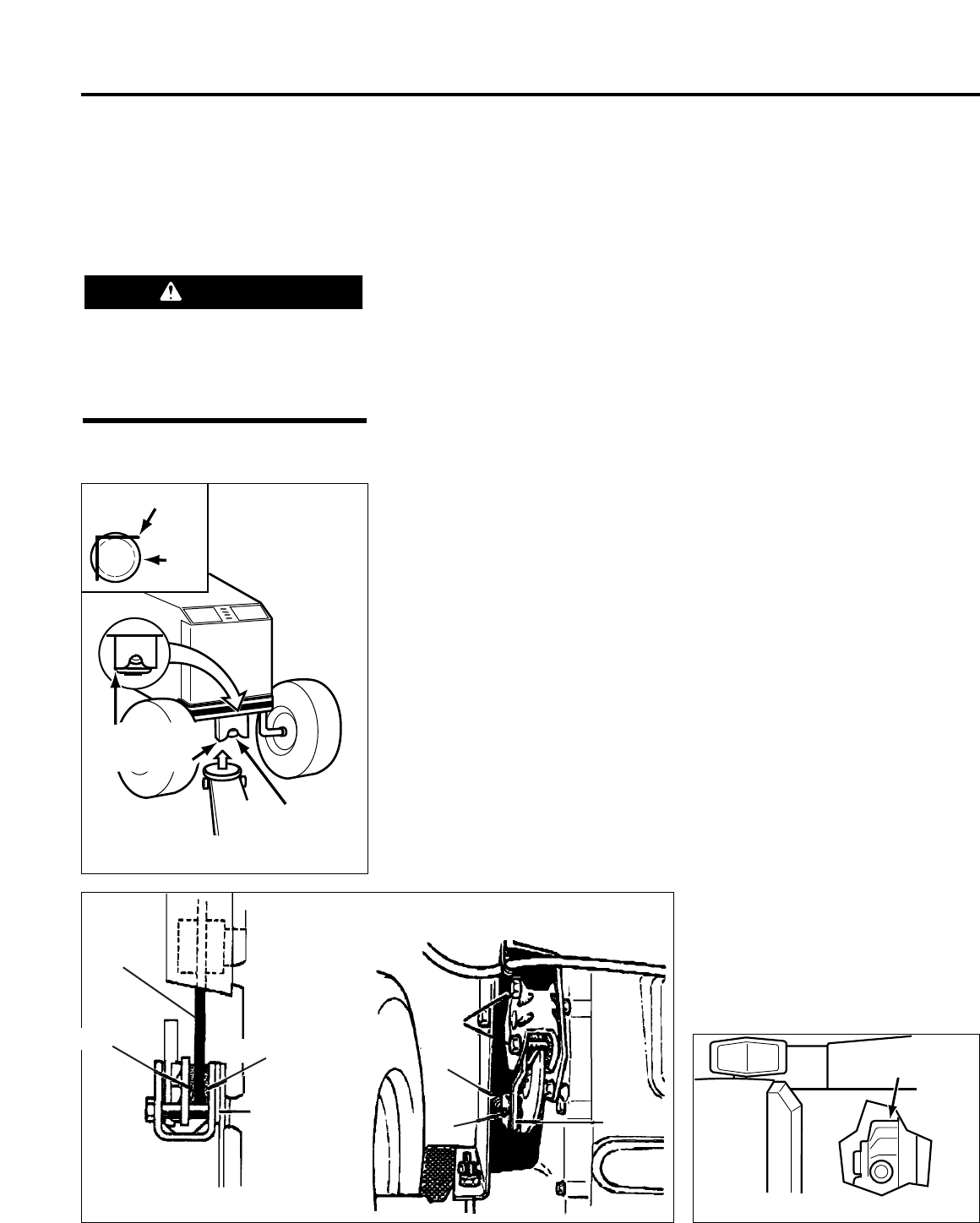

Proper Jack Placement

A floor jack (not a bottle jack) or an

overhead hoist may be used to lift the

front of the tractor. Do not attempt to use

any other device to lift the tractor.

USE EXTREME CARE WHEN JACKING OR

HOISTING TRACTOR. BLOCK WHEELS

AND USE JACKSTANDS TO SECURELY

HOLD UNIT IN PLACE.

WARNING

Fig. 7-7

Do not rest jack

on PTO sheave.

Rest jack on PTO

guard corners.

PTO Guard

Jack

Fig. 7-6

Securely block rear wheels. Rest jack on

attachment/PTO drive guard corners (See

Fig. 7-6). Do not rest jack on PTO sheave.

Interlock Switches

This unit is equipped with interlock safety

switches to help ensure safe start-up and

operation. To test interlock, see page 17.

Attachment/PTO drive switch: Interlocks

are incorporated into the attachment/PTO

drive switch. This switch must be off to

start the engine. Also, if the travel pedal is

pressed into the reverse travel position

while this switch is in the “ON” position,

the PTO will automatically shut off.

Seat: An interlock is positioned behind

the seat. If the operator leaves the seat

without locking brake/neutral pedal and

turning off the attachment/PTO switch, the

engine will stop.

Brake/Neutral linkage (ignition):

Brake/neutral pedal must be pressed to

start the engine.

Brake/Neutral linkage (cruise control):

When the brake/neutral pedal is pressed,

the circuit for the cruise control switch is

open. All power to the cruise control is

shut off.

Brake Adjustment

During normal operation of this machine,

the brakes are subject to wear and will

J

Fig. 7-8

require periodic examination and

adjustment.

To adjust:

1. Turn off engine. Make sure unit is on

a flat surface and block the wheels of

the tractor to prevent it from rolling.

2. Move brake pedal to the disengaged

(released) position.

3. To adjust yoke assembly (V, Fig. 7-7),

remove clevis pin (W). Turn yoke

assembly clockwise.

4. Press and release brake several

times. Re-check and re-adjust as

necessary.

Hydrostatic Maintenance and

Lubrication

Perform the following procedure every 25

hours of operation.

1. Remove all dirt from around

transmission filler area. Clean

transmission cooling fins (J, Fig. 7-8).

If tractor is operated in a dusty

environment, check and clean cooling

fins more frequently.

2. When transmission is cold, check

transmission fluid level. Check level

indicated on dipstick (beneath seat).

Transmission Oil: Change transmission

oil after first five hours and every 100

hours thereafter. Plug is located on front

side of transmission.

2-Speed Models: Fill with part number

737-0333. Alternate fluids: Mobil 423,

Amoco 1000 or Texaco TDH.

1-Speed Models: Fill with part number

737-0335 or a SAE 20 weight motor oil.

Brake Pad

Brake Pad

T

S

V

U

C

W