Operation (continued)

17

Interlock System

Leaving the seat while the attachment/PTO

drive switch (X, Fig. 6-1) is on or while the

brake is off will stop the engine.

DO NOT OPERATE THE UNIT IF THE

INTERLOCK SYSTEM DOES NOT

FUNCTION PROPERLY.

Interlock System Test Procedure: With

the engine running, stop tractor on a level

surface (do NOT engage brake) and raise

yourself off the seat. Engine should stop.

Engage brake and press the

attachment/PTO drive switch (X, Fig. 6-1)

to “ON”. Raise yourself off the seat.

Engine should stop. If the engine does

not stop in both instances, do not operate

the unit. Have the interlock repaired. With

engine running and PTO drive switch (X,

Fig. 6-1) in the “ON” position, move the

travel pedal (M, Fig. 6-1) into the reverse

travel position. The PTO should

automatically shut off. If it doesn’t, do not

operate the unit and have the interlock

repaired.

Perform Electric Clutch Break-in

Procedure

Start the engine as instructed on page 16.

With the engine running at full (fast)

speed, engage and disengage

attachment/PTO drive switch (X, Fig. 6-1)

10 to 15 times. Perform this step before

initial use and after extended storage.

Attachment/PTO Drive

To engage the attachment/PTO drive,

press attachment/PTO drive switch

(X, Fig. 6-1) to “ON”.

Hydraulic Attachment Lift

Pull attachment lift lever (K, Fig. 6-1) back

to lift attachment. Push lever forward to

lower attachment. When lever is released,

it will return to neutral, except when

WARNING

connections to prevent debris from

entering the hydraulic system.

KEEP HYDRAULIC CONNECTIONS CLEAN.

Dirty hydraulic connections can

contaminate the hydraulic fluid and

damage hydraulic components.

DIRTY HYDRAULIC CONNECTIONS CAN

CONTAMINATE THE HYDRAULIC FLUID

AND DAMAGE HYDRAULIC

COMPONENTS. KEEP RUBBER PLUGS IN

PLACE. NEVER USE HANDS TO FEEL

FOR HYDRAULIC LEAKS. HOT

HYDRAULIC FLUID LEAKING AT HIGH

PRESSURE COULD PENETRATE SKIN.

USE ONLY TROY-BILT

®

APPROVED

ATTACHMENTS. Other attachments could

damage the hydraulic system and void the

warranty.

INSPECT ALL HYDRAULIC COMPONENTS

FOR HIGH PRESSURE LEAKS BEFORE

TESTING OR REPAIRING. Never “feel” for

leaks. Oil leaking at high pressure could

penetrate skin. Operating temperatures of

hydraulic fluids are extremely high.

WARNING

pushed fully forward to “FLOAT” position.

Use the “FLOAT” position to allow the

attachment to follow ground contours.

Auxiliary Hydraulic Lever (20 HP Units):

Pull auxiliary hydraulic lever (L) back to

activate auxiliary hydraulic attachment.

Push lever forward to reverse direction.

BEFORE USING HYDRAULIC LEVERS,

MAKE SURE THE ATTACHMENT IS

COMPLETELY HOOKED UP. MOVE

ATTACHMENT THROUGH THE COMPLETE

LIFT RANGE SLOWLY TO MAKE SURE

THERE IS NO INTERFERENCE. MAKE

ADJUSTMENTS IF NECESSARY.

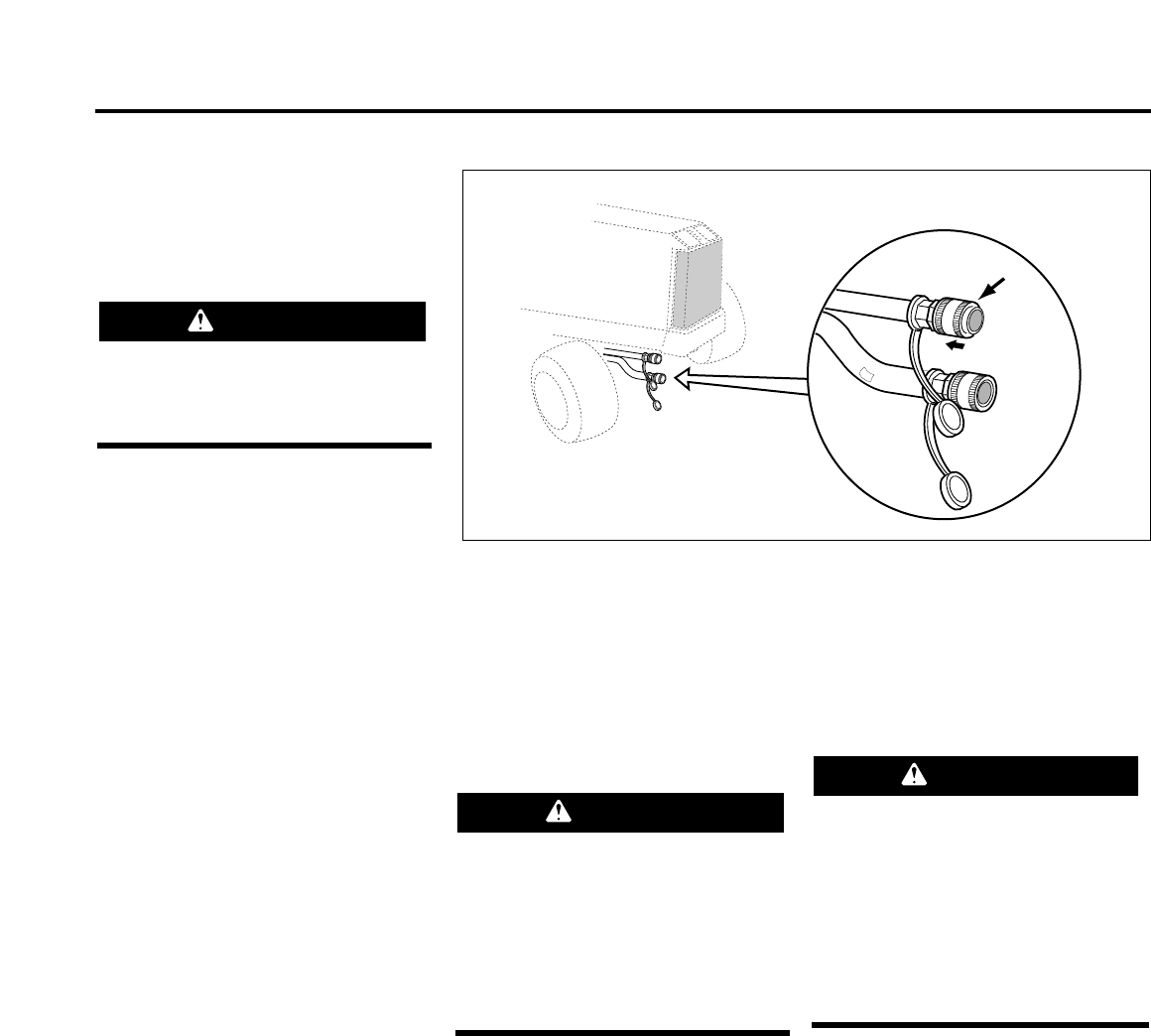

Auxiliary Hydraulic Connections

(Model 13076 Only)

Connections for auxiliary hydraulics (see

Fig. 6-2) are on the front, right-side of the

frame.

To use these connections, remove rubber

plugs. Clean all dirt and debris from

around connections. Push coupling (Q)

back. Insert hydraulic hose end.

When auxiliary connections are not in use,

secure the rubber plugs over the

WARNING

1. Push coupling (Q) back.

2. Install hydraulic hose end.

3. Release coupling.

Q

Fig. 6-2

AUXILIARY HYDRAULIC CONNECTIONS (MODEL 13076 ONLY)