IMPORTANT: If the handlebar height is

changed, the hole position of the Forward

Clutch rod must be changed accordingly.

Changing the handlebar height changes

the tension on the Forward Clutch rod –

this tension must be adjusted by relocat-

ing the rod in the appropriate hole in the

clutch swivel plate.

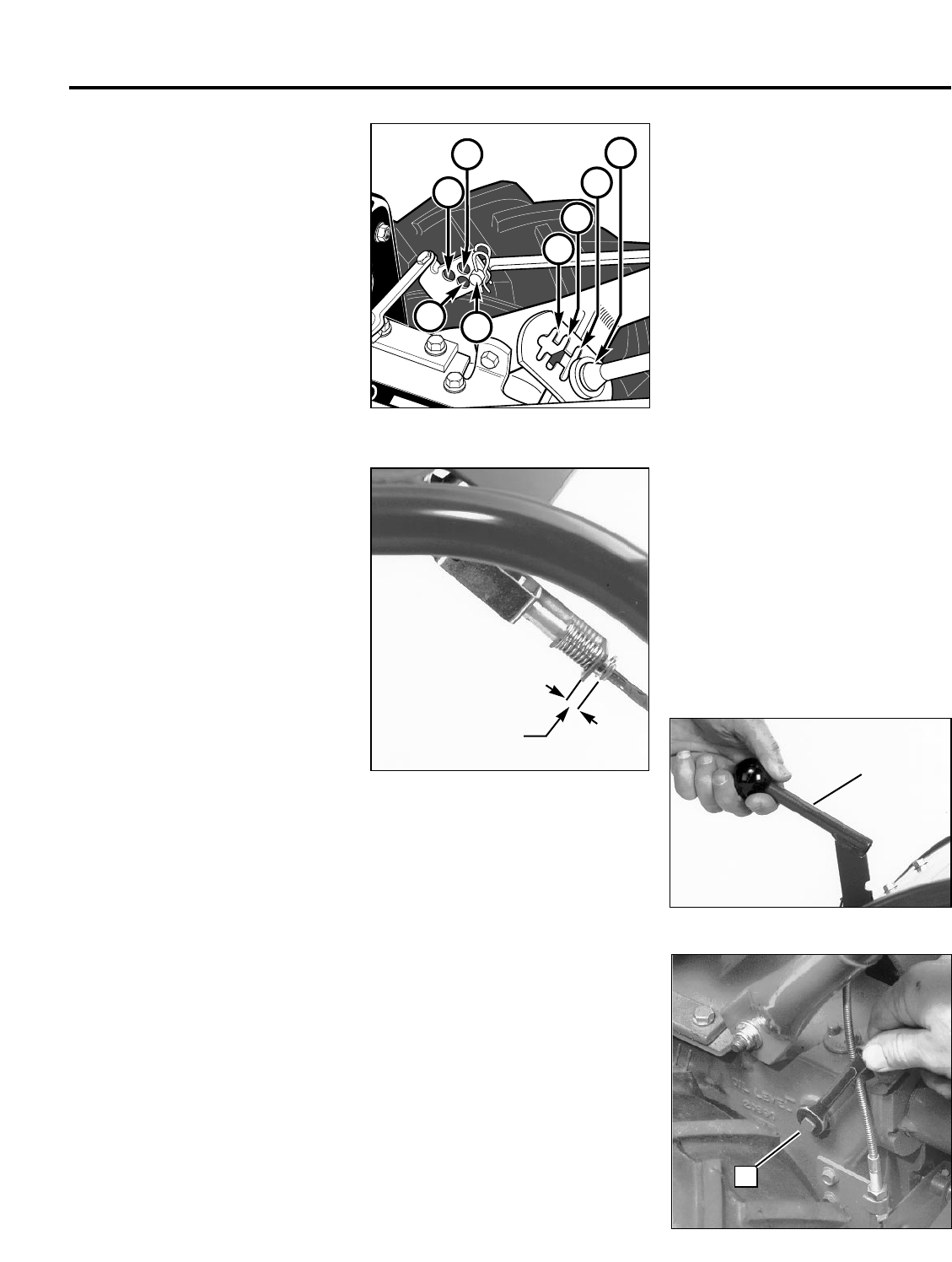

4. Select the proper hole in the clutch

swivel plate and insert the Forward Clutch

rod with the tip facing inward (see Figure

2-8). Secure the rod by inserting a

second hairpin cotter through the hole

near the tip of the rod.

5. Check for correct tension on the

Forward Clutch rod as follows:

(a) Two interconnected Forward Clutch

paddles hang beneath the handlebar

grips. Lift and hold the right-side

paddle against the handlebar grip.

(b) While squeezing the paddle, measure

the gap between the E-ring and the

lower end of the clutch rod bracket

(see Figure 2-9). The gap should be

3/16"-to-5/16". NOTE: A stack of five

pennies is approximately 5/16" thick.

(c) If the gap is incorrect:

(1) First check that the Forward Clutch

rod is in the correct hole in the

clutch swivel plate. If not, reposi-

tion the rod and repeat Step 5b.

(2) If the Forward Clutch rod is in the

correct hole and the gap is incor-

rect, you will need to adjust the

length of the Forward Clutch rod.

To do this, first release the

Forward Clutch paddle and then

disconnect the rod from the clutch

swivel plate.

If the gap is more than 5/16", rotate

the rod counterclockwise (as

viewed from the front of tiller) to

decrease the gap. Reinstall the rod

in the correct clutch swivel plate

hole, secure it with the hairpin

cotter, and repeat Steps 5a and 5b.

If the gap is less than 3/16", rotate

the rod clockwise (as viewed from

the front of tiller) to increase the

gap. Reinstall the rod in the correct

clutch swivel plate hole, secure it

with the hairpin cotter, and repeat

Steps 5a and 5b.

STEP 5: Check Gear Oil

Level in Transmission

The transmission was filled with gear oil

at the factory. However, be sure to check

the oil level at this time to make certain it

is correct.

IMPORTANT: Do not operate the tiller if

the gear oil level is low. Doing so will

result in severe damage to the transmis-

sion components.

1. With the tiller on level ground, pull the

Depth Regulator Lever (L, Figure 2-10)

back and then slide it to the second notch

from the top. NOTE: If the lever does not

move, lift the tine hood flap and look for a

plastic tie securing the lever in place. Cut

and remove the tie.

8

Section 2: Assembly

SERIAL NUMB

1

3

2

4

2

3

4

1

Figure 2-8: Numbered settings for handlebar

height slots and clutch swivel plate holes.

Figure 2-9: While squeezing Forward Clutch

paddle, measure gap between end of

bracket and E-ring.

Gap should be

3/16"-to-5/16"

2. Remove the oil level check plug (M,

Figure 2-11) on the left-side of the trans-

mission. (Due to dried paint on the plug

threads, it may require some force to

remove the plug the first time.) The gear

oil level is correct if oil starts to flow out

of the hole as the plug is removed. If so,

securely reinstall the plug.

3. If oil does not flow from the check

hole, add oil as follows:

NOTE: Do not use automatic transmission

fluid or motor oil in the transmission.

(a) Clean area around oil fill hole (N,

Figure 2-12) and unscrew oil fill plug.

(b) If adding only a few ounces of gear oil,

use API rated GL-4 or GL-5 gear oil

having a viscosity of SAE 140, SAE

85W-140 or SAE 80W-90. If refilling

an empty transmission, use only GL-4

gear oil having a viscosity of SAE

85W-140 or SAE 140.

(c) Using a clean funnel, slowly add gear

oil until it flows from the oil level check

hole (M, Figure 2-11). Securely rein-

stall the oil level check plug (M).

(d) Reinstall and hand-tighten the oil fill

plug (N).

Figure 2-10: Put lever in second notch.

Figure 2-11: Gear oil level check plug.

L

M