23

Section 5: Maintenance

WARNING Before inspecting, cleaning or servicing the unit, shut off engine, wait for all parts to come to a

complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key on elec-

tric start models. Failure to follow these instructions can result in serious personal injury or

property damage.

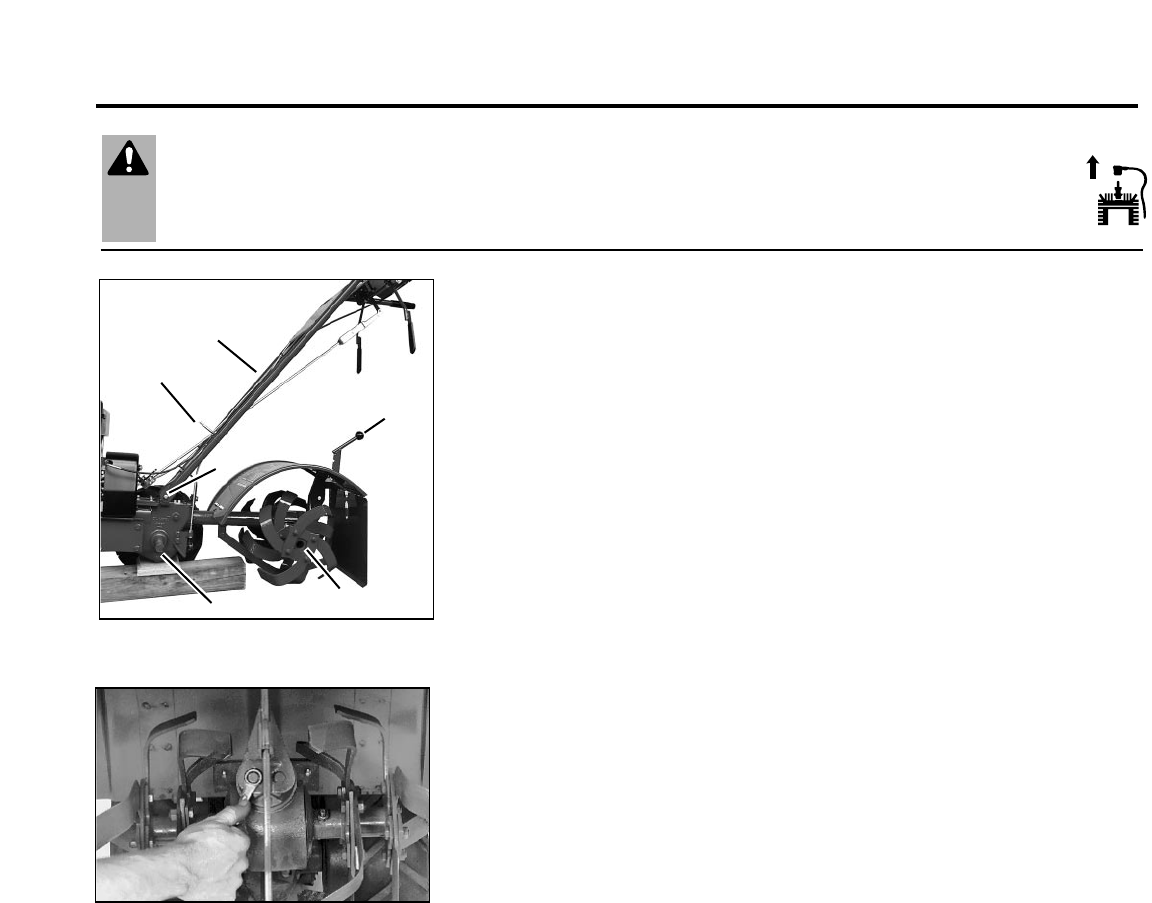

CHECK HARDWARE

At least every 10 operating hours, check

the unit for loose or missing hardware

(screws, bolts, nuts, hairpin cotters, etc.).

Loose or missing hardware can lead to

equipment failure, poor performance or

oil leaks.

Be sure to check the three end cap

mounting screws located at the rear of the

transmission (Figure 5-2). Lift the tine

flap to service those screws.

CHECK TIRE PRESSURE

Check the air pressure in both tires.

Deflate or inflate both tires evenly to 15-

to-20 PSI (pounds per square inch). Be

sure that both tires have the same air

pressure or the unit will tend to pull to

one side.

Figure 5-1

Figure 5-2

A

B

C

F

D

E

F

CHECK FOR OIL LEAKS

Before each use, check your tiller for

signs of an oil leak – usually a dirty, oily

accumulation either on the unit or on the

floor where it has been parked.

A little seepage around a cover or oil seal

is usually not a cause for alarm. However,

if the oil drips overnight then immediate

attention is needed as ignoring a leak can

result in severe transmission damage.

If a cover is leaking, try tightening any

loose screws or bolts. If the fasteners are

tight, a new gasket or oil seal may be

required. If the leak is from around a

shaft and oil seal, the oil seal probably

needs to be replaced. See your autho-

rized dealer or contact the factory for

service or advice.

IMPORTANT: Never operate the tiller if

the transmission is low on oil. Check the

oil level after every 30 hours of operation

and whenever there is any oil leakage.

TRANSMISSION GEAR OIL SERVICE

Check the transmission gear oil level after

every 30 hours of operation or whenever

you notice any oil leak. Operating the

tiller when the transmission is low on oil

can result in severe damage.

A. To Check Transmission Gear Oil

Level:

1. Check the gear oil level when the trans-

mission is cool. Gear oil will expand in

warm operating temperatures and this

expansion will provide an incorrect oil

level reading.

2. To check the gear oil level (and to add

oil, if necessary), refer to “STEP 5: Check

Gear Oil Level in Transmission” in Section

2 of this manual.

B. To Drain and Refill the Transmission:

The transmission gear oil does not need

to be changed unless it has been contami-

nated with dirt, sand or metal particles.

1. Prop up the left side of the unit so that

it will be securely supported when the left

side wheel is removed. Remove the left

side wheel by removing the wheel mount-

ing hardware.

2. Unscrew the plastic gear oil fill plug

from the top of the transmission.

3. Place a clean pan below the transmis-

sion drain plug (see Figure 5-3) and

remove the drain plug. The oil will start

flowing out of the drain hole (it may flow

slowly, especially in cold temperatures).

4. Remove the transmission gear oil level

check plug that is located a few inches

above the left side wheel shaft.

5. When the oil stops flowing, tilt the

transmission forward to drain oil from the

rear of the transmission.

6. After draining the oil, clean the threads

of the drain plug, apply a non-hardening

removable gasket sealant to the threads,

and securely reinstall the drain plug.

7. Using a clean funnel, slowly add SAE

140 or SAE 85W-140 weight gear oil

(with an API rating of GL-4 only) to the

transmission. The transmission holds

approximately 3-1/4 pints (52-54

ounces). Tilt the tiller slightly backwards

to make sure the gear oil reaches the rear

(tine) end of the transmission. Stop

adding

gear oil when it begins to flow from the

oil level check hole on the side of the

transmission.

8. Securely reinstall the oil level check

plug.

9. Securely reinstall the gear oil fill plug

on top of the transmission.

10. Reinstall the wheel and remove the

prop.