Figure 6

1. Move the machine to a level surface.

2. Clean around the oil ll cap (Figure 11).

3. Unscrew the oil ll cap and remove it.

4. Slowly pour oil into the oil ll hole. Wait 3 minutes,

then check the oil level on the dipstick by wiping the

dipstick clean and then inserting, but not screwing

in, the oil ll cap into the hole.

Note: To determine the proper oil level on the

dipstick, refer to

Figure 7.

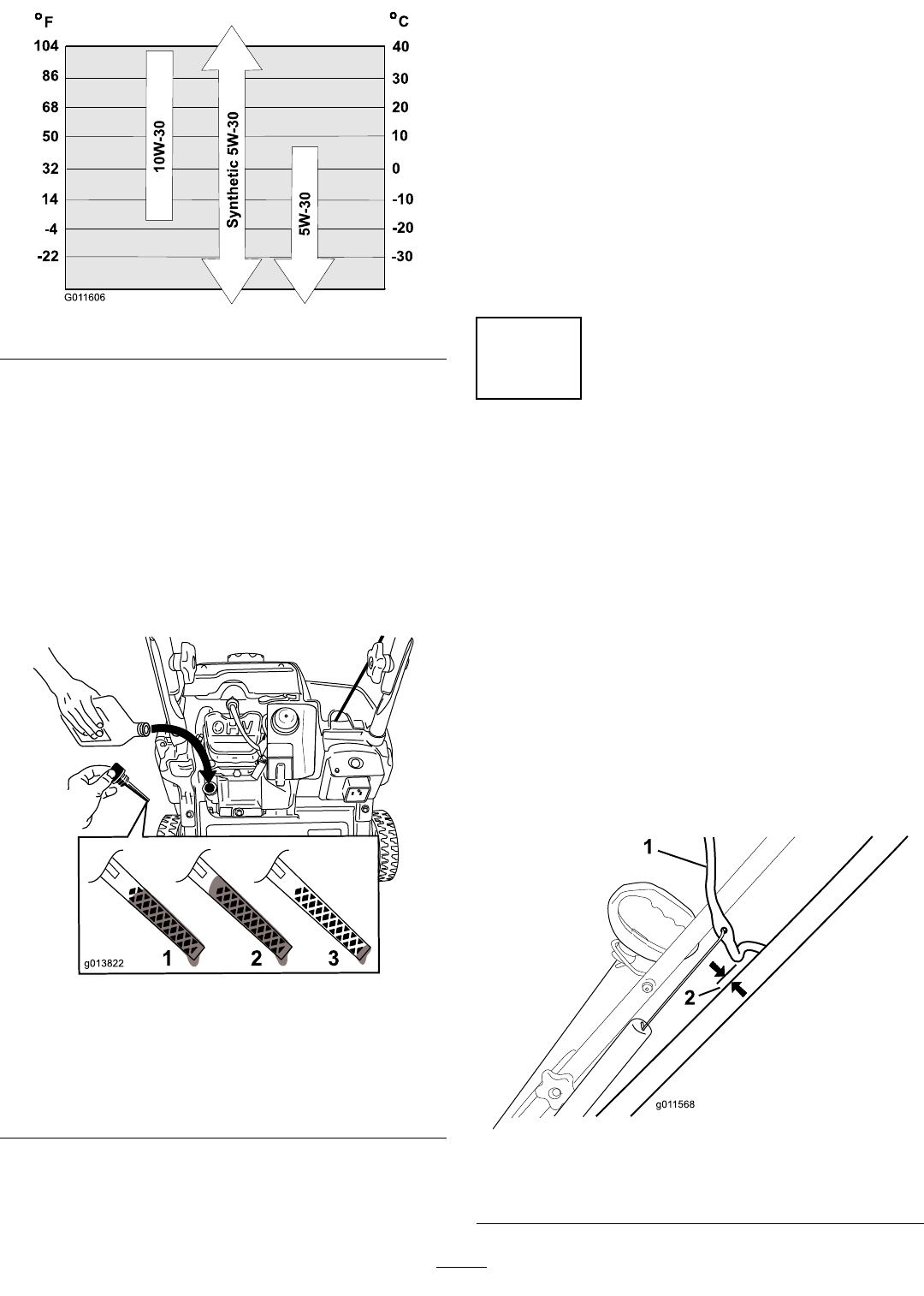

Figure 7

1. The oil level is at its

maximum.

3. The oil level is too

low—add oil to the

crankcase.

2. The oil level is too

high—remove oil from

the crankcase.

Note: Fill the engine crankcase with oil until the

dipstick indicates that the engine oil level is correct

as shown in Figure 7. If you overll the engine with

oil, remove the excess oil as directed in Changing

the Engine Oil.

Note: You may tip the machine forward (handle

up) a little to make adding oil easier. Remember to

return the machine to the operating position before

checking the oil level.

Important: Do not tip the machine all the way

forward onto its nose, or fuel may leak out of

the machine.

5. Screw the oil ll cap into the oil ll hole and hand

tighten it securely.

5

Adjusting the Control Cable

No Parts Required

Checking the Control Cable

Service Interval: After the rst hour—Check

the control cable and adjust it if

necessary.

Yearly—Check the control cable and

adjust it if necessary.

Important: You must check and may need to

adjust the control cable before you operate the

machine for the rst time.

Move the control bar back toward the handle to remove

the slack in the control cable (

Figure 8).

Figure 8

1. Control bar 2. 1/16 to 1/8 inch (2 to 3

mm)

7