42 Reel Mowers

Toro University Technical Training

Reel Grinding

Grind parallel to the Reel Shaft

Do Not

grind by equaling the spark pattern on each end

A

B

A = B

Whichever grinder you use, be sure to compensate

for a cone or barrel shaped condition.

Grind parallel to the Reel Shaft. Do Not

setup the

grinder by simply equaling the spark pattern on

each end. This will not remove the slight cone

shape of the worn reel.

Reels naturally wear more on one end then the

other.

Verify the reel centerline, which is the reel shaft, is

parallel to the grinder stone travel.

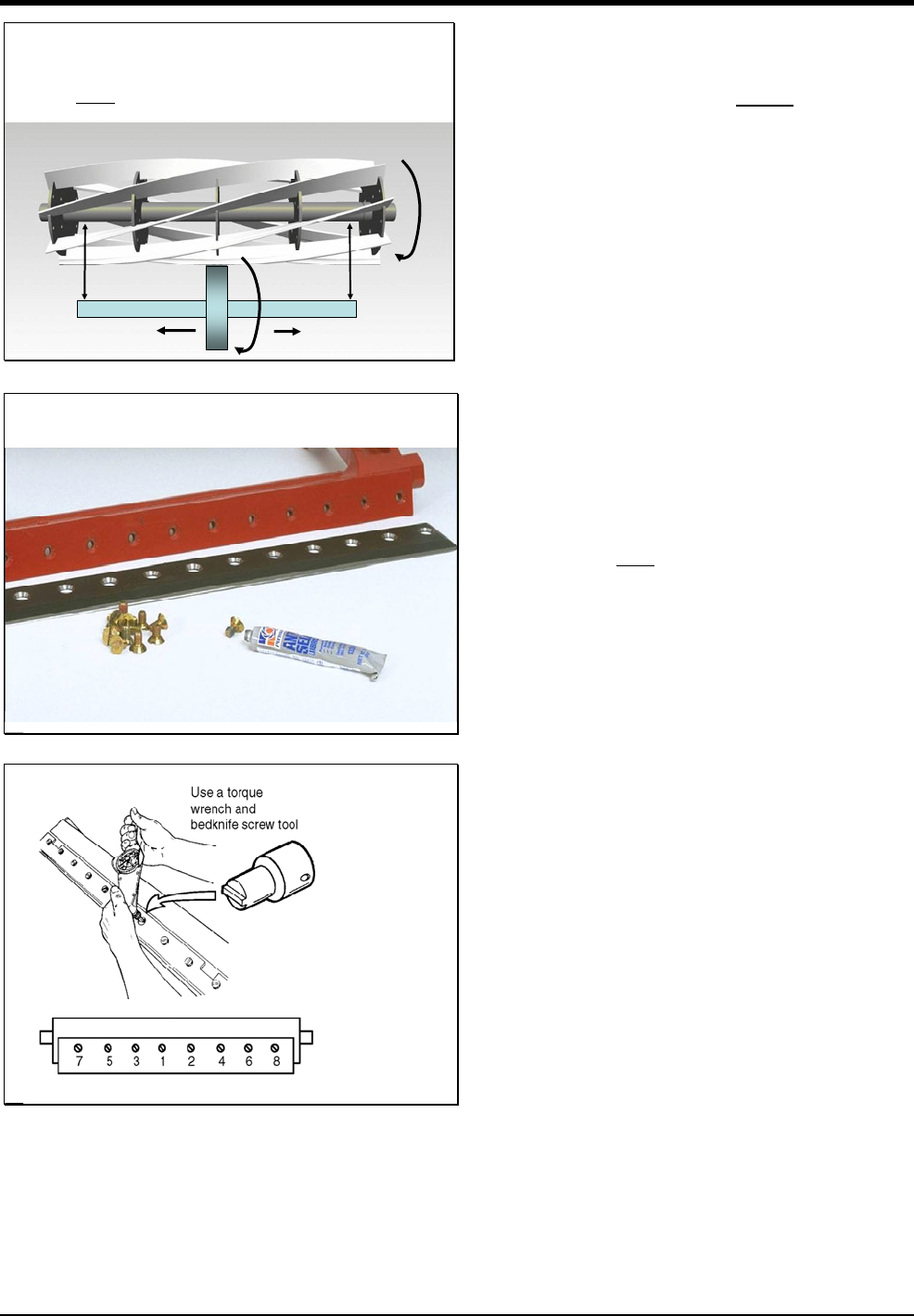

Bedknife Installation

If replacing the bedknife it is important to use the

following procedures:

• Remove all rust, scale and corrosion from

the bedbar surface before installing new

bedknife.

• Make sure the bedbar threads are clean.

• Use new Toro

screws. Apply anti–seize

lubricant to the screw threads before

installing.

Fairway and Utility Mowers:

250 – 300 in-lb. (288 - 345 KgCm)

Greens Mowers:

200 – 250 in-lb. (230 - 288 KgCm)

Tighten the screws working from the center toward

each end of the bedbar. Do not use an impact

wrench.

Fairway/utility mowers:

250 – 300 in-lb. (288 – 345 KgCm)

Greens mowers:

200 - 250 in-lb. (230 - 288 KgCm)

Since there can be variations in the mounting

surface of the bedbar, a new bedknife may not be

perfectly flat after it is installed. Because of this, it is

necessary to backlap or grind a new bedknife after

installing it to the bedbar. Follow the existing angle

that was ground into the bedknife and grind only

enough to make sure the top surface is true.