29

Section 5 - ADJUSTMENTS & REPAIR

5.9 HYDRAULIC SYSTEM, PURGING

After replacing or repairing hydraulic system

components, one or both of the wheel drives may

not pull properly. This is likely to be caused by air

entrapped in the system. If you experience a

pulling issue after completing repairs, perform the

following procedure to purge the air from one or

both of the hydraulic drive systems.

IMPORTANT: WHEN REPLACING THE HYDRAULIC

FLUID FILTERS, PRE-FILL BOTH WITH OIL

(SAE 20W50 API SL) BEFORE INSTALLING.

PRE-FILLING THE FILTERS WITH OIL WILL

REDUCE OR POSSIBLY ELIMINATE THE NEED

TO PURGE THE SYSTEM OF ENTRAPPED AIR

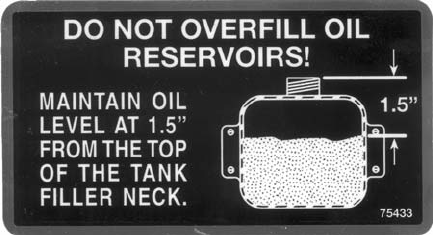

1. Locate hydraulic reservoir underneath

operator’s seat. After thoroughly cleaning the area

around the top of the reservoir, remove filler cap.

Bring fluid to proper level (1 ½” below the top of

the filler neck). With engine off, add SAE 20W50

automotive oil. See Figure 4.6.

2. Open pressure relief valve on hydraulic pump,

turning counter clockwise 2 full turns. See Figure

3.3.

3. Carefully raise the rear of the machine so the

wheels are off of the ground. Securely block the

machine to prevent it from falling.

4. While seated in the operator’s position, start the

engine. Place engine speed control in FAST

position.

5. Release parking brake and move motion

control levers out of the neutral lock position.

6. Slowly move motion control levers to the full

forward and then to the full reward positions.

Repeat this process 6 times.

7. Stop engine and wait for all rotation to stop

before leaving the operator’s position.

8. Close pressure relief valve on hydraulic pump,

turning clockwise. Tighten snuggly.

9. With pressure relief valve closed, repeat Steps

4 thru 7.

10. Remove blocks and lower rear of machine.

11. Check fluid level in reservoir. Add SAE 20W50

automotive oil as required to bring fluid level to 1

½” from top of filler neck. Do Not over fill.

12. Install and tighten filler cap.