PRIMARY MAINTENANCE

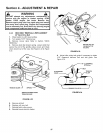

Generally, wash foam-type filters

In a dlshwashlng detergent and

water solution. Rinse and wring

dry, then saturate with oll and

squeeze out excess. Failure to

re-oil this type filter will ruin the

engine.

Clean paper elements by tapping

lightly. Blowing with air will

ruPture paper elements.

Use a flashlight to detect clogged

or torn paper elements - replace if

damaged in any way.

Air Is also needed to keep

your engine cool. Dirt, dust

& debris bund up to restrict

and clog cooling air intake

screens and fins. Clean

screens and fins at frequent

Intervals. The engine blower

housing and shrouds should

be removed at least once

each season or more often

under dry, dusty conditions

ifor a thorough cleaning of

fins.

Failure to keep external

surfaces clean not only

presents fire hazards, but

causes overheating and

resulting engine damages

such as:

1. distorted valve guides

2. sticking valves

). 3. scuffed

walls

} 4. oversl_dlng

5. loss of power

6. complete failure of

engine.

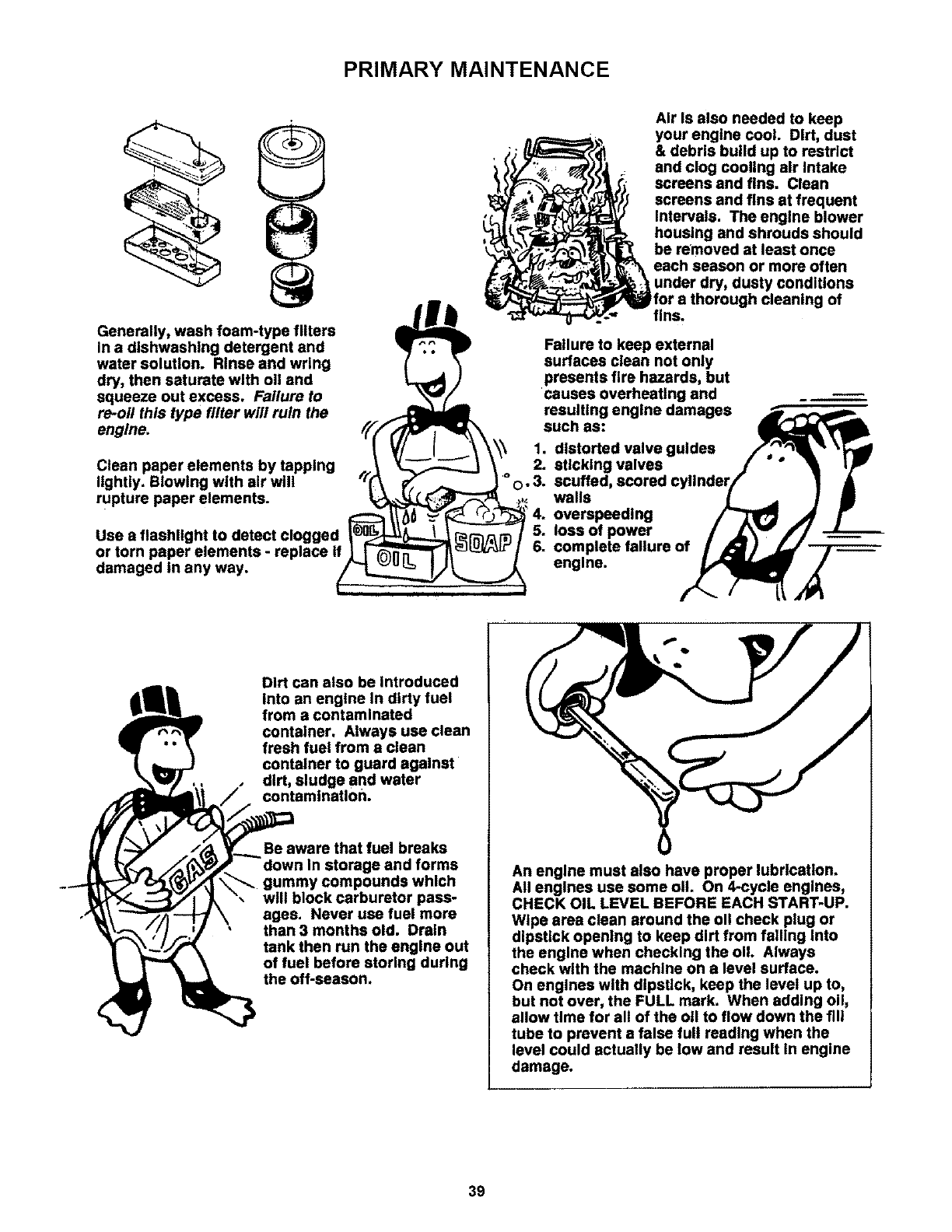

Dirt can also be Introduced

into an engine In dirty fuel

from a contaminated

container. Always use clean

fresh fuel from a clean

container to guard against

dirt, sludge and water

contamination.

Be aware that fuel breaks

down In storage and forms

lummy compounds which

will block carburetor pass-

ages. Never use fuel more

than 3 months old. Drain

tank then run the engine out

of fuel before storing during

the off-eeason.

An engine must also have proper lubrication.

All engines use some oil On 4-cycle engines,

CHECK OIL LEVEL BEFORE EACH START-UP.

Wipe area clean around the oll check plug or

dipstick opening to keep dirt from falling Into

the engine when checking the o11.Always

check with the machine on a level surface.

On engines with dipstick, keep the level up to,

but not over, the FULL mark. When adding o11,

allow time for all of the oil to flow down the fill

tube to prevent a false full reading when the

level could actually be low and result In engine

damage.

39