18

Section 4 - ADJUSTMENTS & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance,

service or repairs with the engine running. STOP

engine. STOP blades. Engage parking brake. Remove

key. Remove spark plug wire from spark plug and

secure away from plug. Engine and components are

hot. Avoid serious burns by allowing all parts to cool

before working on machine.

4.3 MOWER BLADE DRIVE BELTS – ADJUSTMENT /

REPLACEMENT (continued from previous page)

2. Remove cover to gain access to the belt, idler and

control cable area. The cover is retained to the seat

pedestal with four screws. See Figure 3.4.

3. Visually inspect condition of belt. If worn or

damaged, replace. Refer to Section “ENGINE TO

DECK BELT REPLACEMENT” for instructions.

4. With engine stopped, move blade control lever to

the ON position. The control cable spring should

extend between 3/8” & 1/2”. See Figure 3.5. If spring

extension is less than 1/4”, adjustment is required.

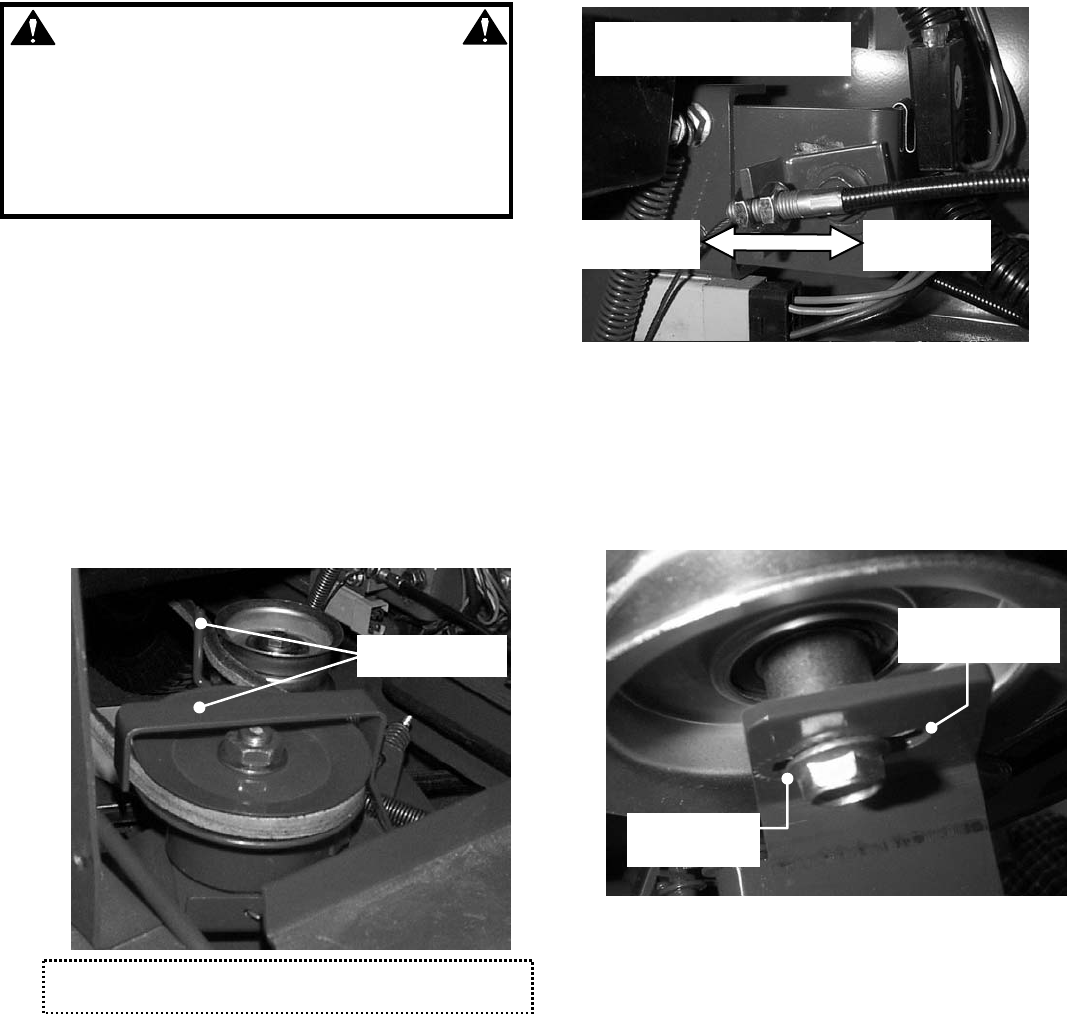

FIGURE 4.3

5. The threaded fitting on the end of the control cable

provides fine tension adjustments. See Figure 4.4.

Loosen jam nuts and turn nuts until spring extension

falls in the range of 3/8" to 1/2". Tighten nuts securely.

Move blade control lever to the OFF position. Install

cover (refer to note below) and tighten screws

securely.

NOTE: If the threaded fitting adjustment did not

produce proper spring extension, leave cover off and

proceed to next step.

FIGURE 4.4

6. If step 5 did not produce the correct spring

extension, the idler pulley will require repositioning.

The idler arm has a series of 4 holes. See Figure 4.5.

The #1 position produces the highest belt tension, #4

the lowest. Remove the idler pulley – noting the

mounting hole location prior to removing bolt.

FIGURE 4.5

7. Reposition the idler pulley one hole at a time in the

desired direction (higher tension or lower tension).

Install bolt and nut. Tighten securely.

IMPORTANT: DO NOT over tension belt. Excessive

tension will adversely affect belt drive function and

can cause damage.

8. Check belt tension. Repeat step 4. Use threaded

fitting on cable for fine adjustment (refer to step 5).

DO NOT exceed 1/2” spring extension.

NOTE: The rear deck brackets are slotted where they

attach to the deck. This provides adjustment to

accommodate variations in belt length. Loosen nuts

(4) and slide deck forward to increase engine to deck

belt tension.

#4 - LOWEST

TENSION

#1 - HIGHEST

BELT TENSION

CONTROL CABLE TENSION

ADJUSTMENT. MOVE NUTS.

INCREASE

TENSION

DECREASE

TENSION

NOTE: POSITION BELT GUIDES 1/8” FROM BELT WITH

BLADE CONTROL ON (ENGINE OFF).

CONTROL CABLE SPRING EXTENSION RANGE 3/8” &

1/2”

BELT GUIDES