14

Section 3 – MAINTENANCE

FIGURE 3.6

WARNING

The following procedure requires the engine and

blades to be operated. Exercise extreme caution.

Clear area of loose parts & tools first. Only operate

blades when seated in the operator’s seat.

3.2.5. Blade Brake

1. Check blade brake for proper function. Blades

should stop rotating in 3 seconds or less after

moving the blade control lever back to the “OFF”

position.

WARNING

Blades must stop rotating in 3 seconds or less after

blades have been turned off. DO NOT operate

machine until blade brake has been adjusted and

functioning properly.

2. If blades continue to rotate longer than 3

seconds do not operate machine. Refer to Section

“BLADE BRAKE ADJUSTMENT” or contact your

SNAPPER dealer for assistance.

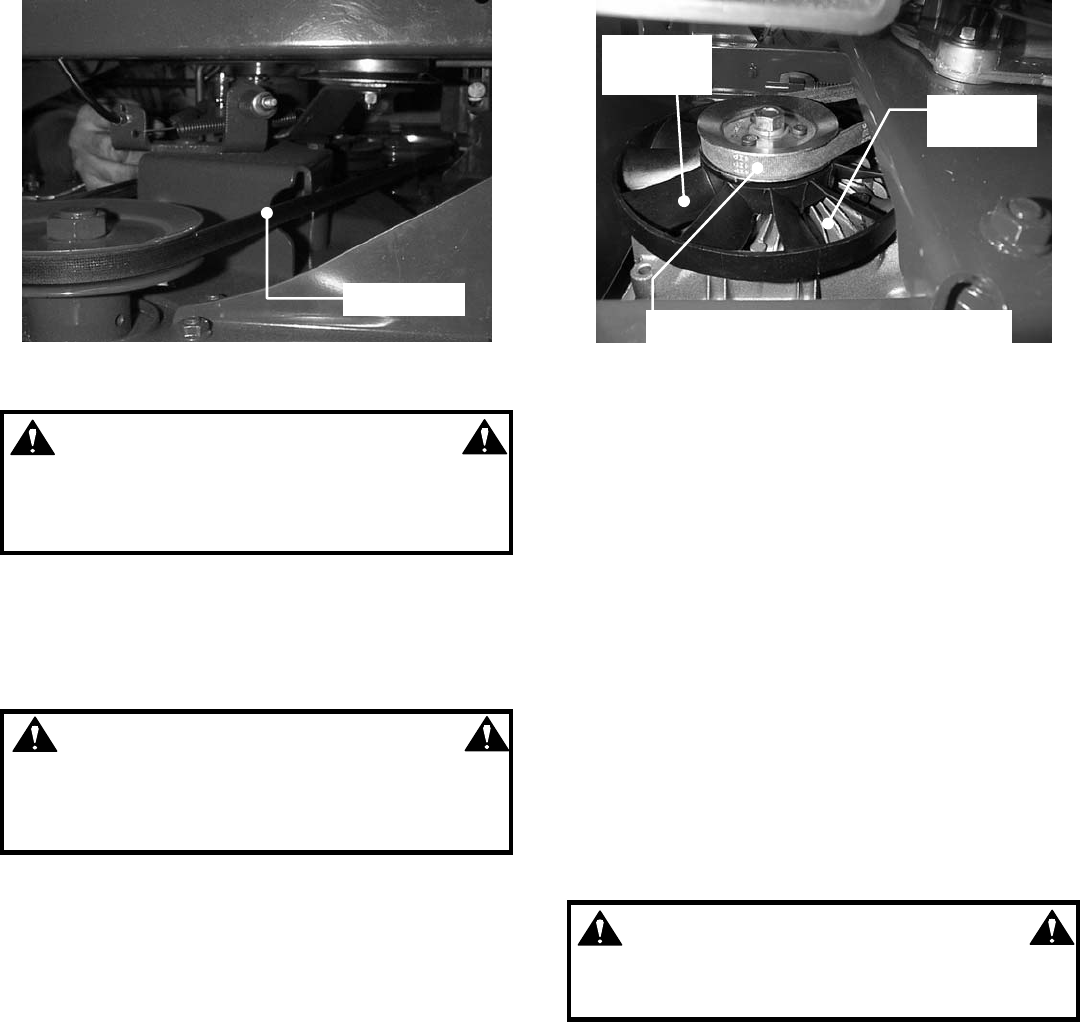

3.2.6. Transmission

1. Transmission belt does not require tension

adjustment. Visually check for signs of

deterioration. Replace if worn or damaged.

Refer to Section “TRANSMISSION BELT

REPLACEMENT”. See Figure 3.7.

2. Transmission belt idler pivot grease fitting

requires lube. Apply 1-3 shots of general purpose

grease from a grease gun. Refer to Section

“LUBRICATION – GREASE FITTINGS”.

3. Transmission requires no fluid level check or

fluid change. Check transmission cooling fan and

cooling fins. Keep these items clean and free of

debris build up. See Figure 3.7.

FIGURE 3.7

3.2.7. Service Brake / Park Brake

1. Check machine brake for proper function.

Engage park brake. Push machine. Rear tires

should skid. Drive machine forward and apply

brake. Machine should come to a complete stop in

less than 5 ft.

2. If brakes are not functioning properly brake

adjustment must be completed before operating

machine. Refer to Section “SERVICE BRAKE –

PARK BRAKE ADJUSTMENT”.

3.2.8. Interlock System

Check interlock controls for proper function:

The engine MUST NOT start if:

1. Blade Control is “ON” and/or clutch / brake

pedal is released.

The engine and blades MUST STOP if:

2. The operator leaves the operator position with

Blade Control “ON” and/or clutch / brake pedal is

released.

WARNING

DO NOT operate machine if interlock system is not

functioning properly. Contact your SNAPPER Dealer

immediately for assistance.

3.2.9. Lubrication - Grease Fittings

The following components on the Hydro Rider are

equipped with grease fittings and require periodic

lubrication. Apply General Purpose grease with a

grease gun. To locate fittings, See Figures 3.8, 3.9,

3.10, 3.11 and 3.12.

1. Front axle pivot, 2-3 shots. See Figure 3.8.

(Continued on next page)

CHECK ENGINE TO TRANSMISSION BELT.

KEEP COOLING FAN & FINS CLEAN.

COOLING

FAN

COOLING

FINS

DECK BELT