Section 4 - REPAIR & ADJUSTMENTS

4.1.5. GROUND SPEED ADJUSTMENT

NOTE: It is recommended to remove the drive system

cover and check rubber drive tire engagement with

drive disc when adjusting ground speed.

1. Tilt machine forward to gain access to drive system

area. Secure machine in the tilted position to prevent

tipping over. Remove drive system cover plate. Refer

to Figure 4.7.

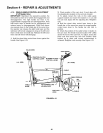

2. Loosen the top screw that connects the shift rod to

the shift hub. See Figure 4.8.

3. Move shift rod clockwise to obtain more ground

speed or counter clockwise for less ground speed.

Retighten top screw after adjustment. See Figure 4.8.

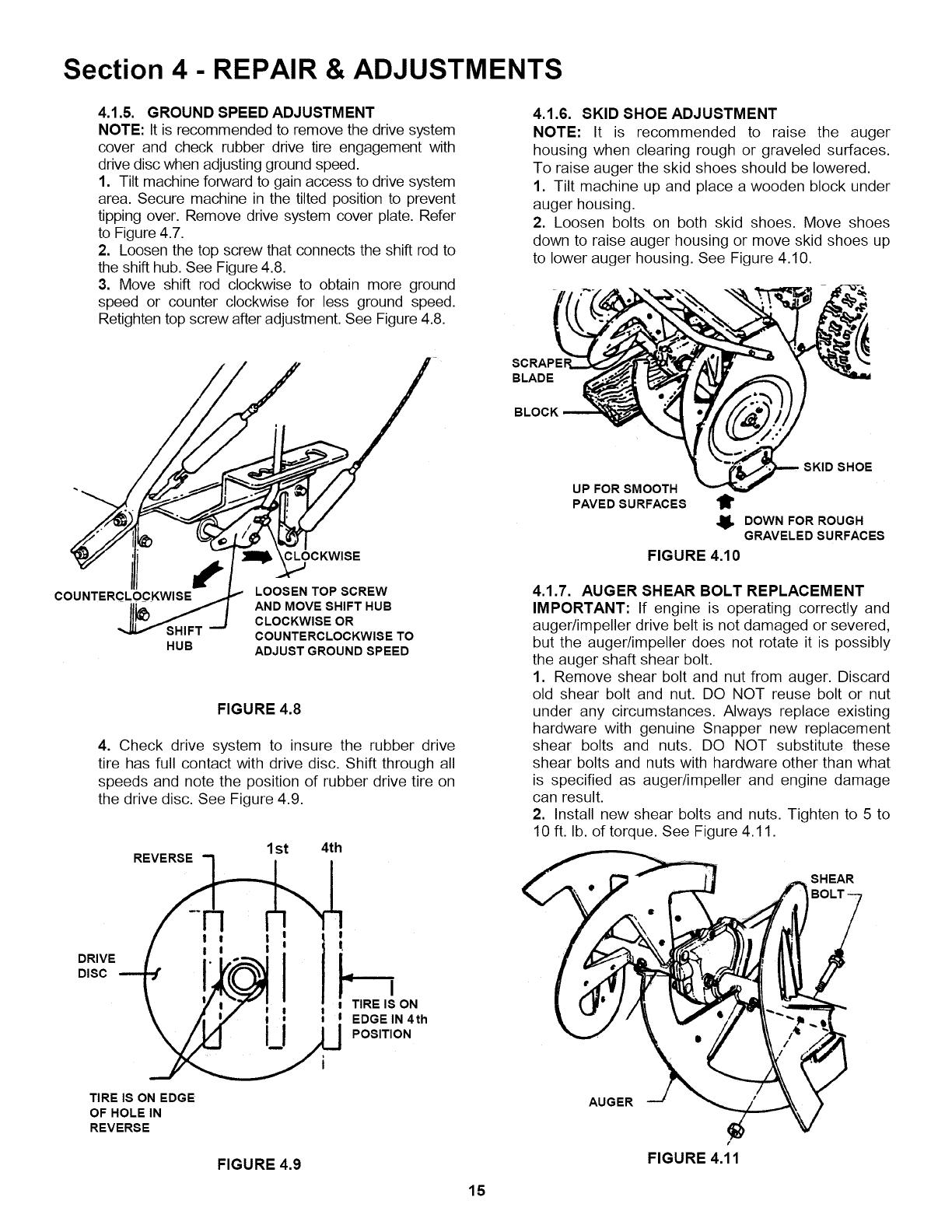

4.1.6. SKID SHOE ADJUSTMENT

NOTE: It is recommended to raise the auger

housing when clearing rough or graveled surfaces.

To raise auger the skid shoes should be lowered.

1. Tilt machine up and place a wooden block under

auger housing.

2. Loosen bolts on both skid shoes. Move shoes

down to raise auger housing or move skid shoes up

to lower auger housing. See Figure 4.10.

SCRAPEF

BLADE

BLOCK

COUNTERCLOCKWISE

SHIFT

HUB

CLOCKWISE

LOOSEN TOP SCREW

AND MOVESHIFTHUB

CLOCKWISE OR

COUNTERCLOCKWlSETO

ADJUST GROUND SPEED

FIGURE 4.8

4. Check drive system to insure the rubber drive

tire has full contact with drive disc. Shift through all

speeds and note the position of rubber drive tire on

the drive disc. See Figure 4.9.

REVERSE

1st 4th

I I

I I

TIRE IS ON EDGE

OF HOLE IN

REVERSE

!

i.

h

! TIRE IS ON

I EDGE IN 4th

POSITION

FIGURE 4.9

15

SHOE

UP FOR SMOOTH

PAVED SURFACES

_. DOWN FOR ROUGH

GRAVELED SURFACES

FIGURE 4.10

4.1.7. AUGER SHEAR BOLT REPLACEMENT

IMPORTANT: If engine is operating correctly and

auger/impeller drive belt is not damaged or severed,

but the auger/impeller does not rotate it is possibly

the auger shaft shear bolt.

1. Remove shear bolt and nut from auger. Discard

old shear bolt and nut. DO NOT reuse bolt or nut

under any circumstances. Always replace existing

hardware with genuine Snapper new replacement

shear bolts and nuts. DO NOT substitute these

shear bolts and nuts with hardware other than what

is specified as auger/impeller and engine damage

can result.

2. Install new shear bolts and nuts. Tighten to 5 to

10 ft. lb. of torque. See Figure 4.11.

SHEAR

AUGER

t

FIGURE 4.11