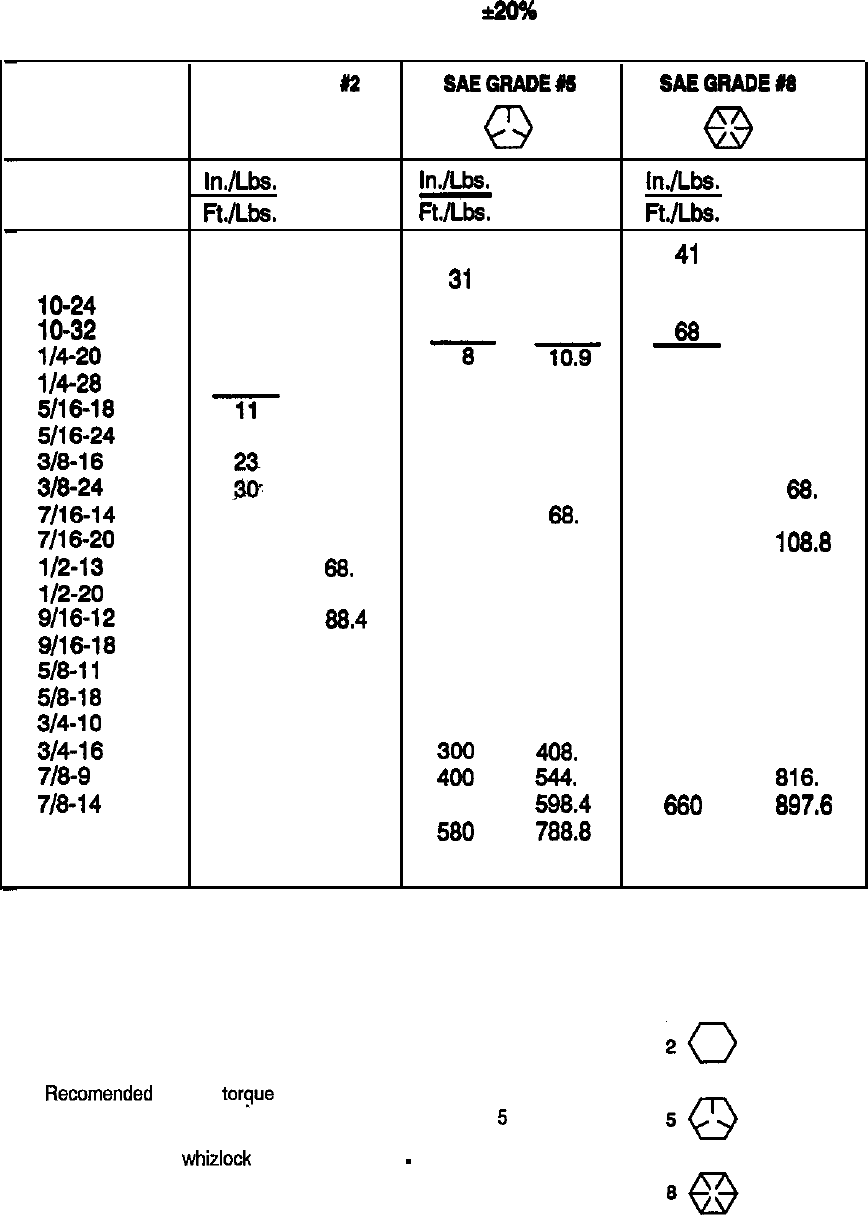

TORQUE SPECIFICATIONS FOR

STANDARD MACHINE HARDWARE

TOLERANCE

4096

SEE

SAE GRADE

R

SAEGRADE#5

SAEGRADEII)

0

Q

Q

h/Lb.

In./Lbs.

InJLbs.

FtJLbs.

Nm.

FtJLbs.

Nm.

FtJLbs.

Nm.

a-32

19 2.1 30 3.4

41 4.8

8-38

20 2.3

31

3.5

43

4.9

lo-24

27 3.1 43 4.9

80

8.8

lo-32

31 3.5 49 5.5

aa

7.7

w-20

88 7.8

8

10.9

12

18.3

114-28

78 8.8 10 13.8

14

19.

S/18-18

-7T

15. 17 23.1

25

34.

5118-24

12 18.3 19 25.8

25

34.

318-18

20 27.2 30 40.8

45

81.2

318-24

35 47.8

50

68.

7118-14

2

31.3

40.8

50

68.

70

95.2

7118-20

35 47.8 55 74.8

80

108.8

l/2-13

50

as.

75 102.

110 149.8

l/2-20

55 74.8 90 122.4

120

183.2

9118-12

85

88.4

110 149.8

150

204.

9118-18

75 102. 120 183.2

170 231.2

5/a-ii

90 122.4 150 204.

220 299.2

518-18

loo 138. 180 244.8

240 328.4

314-10

180 217.8 280 353.8

388

525.

314-18

180 244.8

300

408.

420 571.2

7/a-9

140 190.4

400

544.

800

818.

7/8-14

155 210.8 440

598.4

aa0

897.8

l-a

220 299.2

580

788.8

900

1,224.

1-12

240 328.4 840 870.4

1,000 1,380.

NOTE:

BOLT HEAD MARKING

S.A.E. GRADE:

1. These torque values are to be used for all hardware

excluding: locknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2.

Recomended seating torque values for locknuts:

a. For prevailing torque locknuts. use 65% of grade

5

torques.

b. Forflange whizlock nuts (and screws)

-

use 135%

of grade 5 torques.

3.

Unless otherwise noted on assembly drawings all torque

values must meet this specification.