42” Snow Plow/Dozer Blade

Skid Shoes

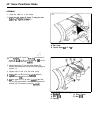

Alternate holes are provided to permit adjustment of

the shoe assemblies for raising and lowering the

blade to various working heights (see figure 11).

When cleaning snow from gravel or earth drives or

walks the shoe assemblies should be lowered fully to

prevent blade contact with gravel or ground. When

cleaning smooth hard surfaces, like concrete, the

shoe assemblies are normally placed fully up to allow

the blade to scrape the surface.

To adjust the skid, raise the blade off the ground and

block with a piece of wood. Loosen the capscrews (A,

figure 11) and move the skid shoes

(6) up or down to

desired height. Tighten the capscrews securely.

Blade Angle

To adjust the angle of the blade, proceed as follows:

1.

Lift the blade off the ground using the tractor lift

lever.

2. Remove the pivot pin (H, figure 1 and E, figure

i),

move the blade to desired angle and reinstall the

pivot pin in a diierent hole.

Spring Tension

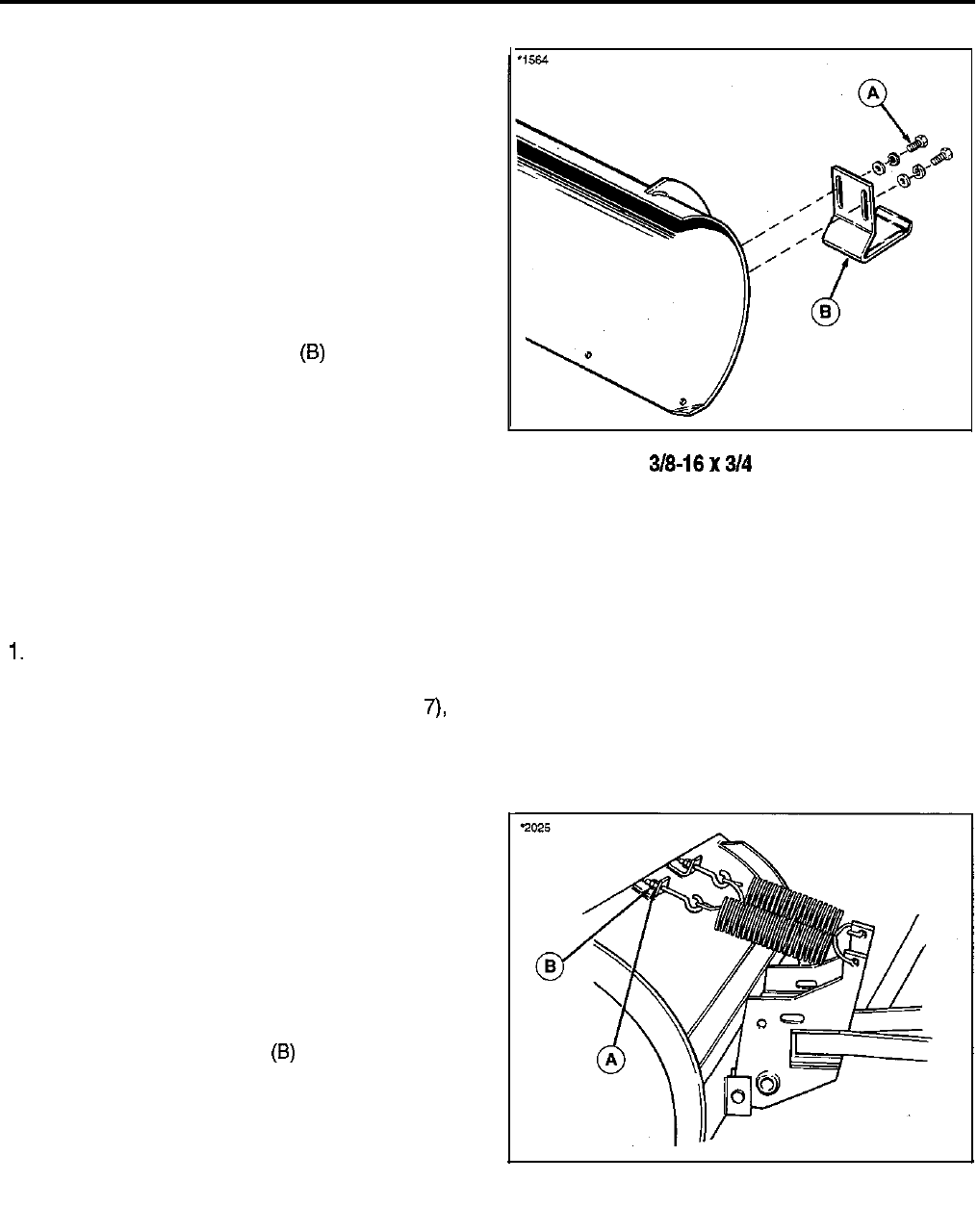

This snow plow/dozer blade is spring loaded so that

when the blade strikes a solid object, the springs will

allow the blade to release as shown in figure 12 rather

than cause damage. The blade will go back to original

position after object is cleared.

To adjust spring tension, hold rear nut (A, figure 12)

and loosen front nut (B). Tighten rear nut (B) to

increase spring tension or loosen nut to decrease

spring tension. Tighten front nut

(8) so the two nuts

are drawn firmly together.

Figure 11. Skid Shoes

A. Capscrews,

3/S-18

x

314

B. Skid Shoes

I

Figure 12. Spring Tension

A. Adjustment Nut (Rear)

B. Jam Nut (Front)

10