14

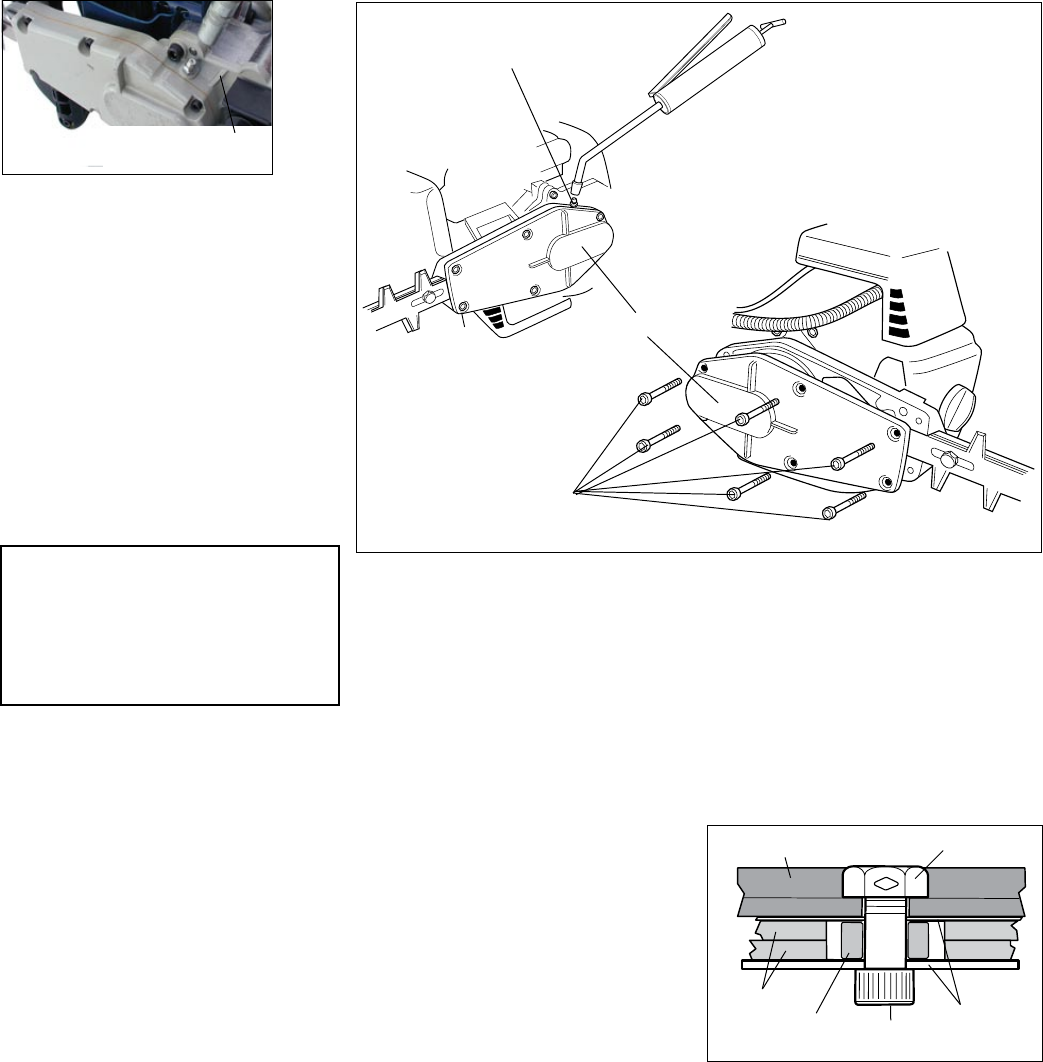

Gearcase Lubrication

VIEWED FROM THE BOTTOM

Gearcase Grease Fitting

Every 20 Hours

Figure 20

Top off gearcase grease level by using

a lever-type grease gun to force 1–2

strokes of high quality lithium-based

grease through the gearcase grease

fitting

Remove the gearcase cover, and use

solvent and a soft brush to remove all old

grease from the gearcase. To refill, hand-

pack the gearcase with approximately

40–50 grams of high quality lithium-

based grease (50–70% of capacity). DO

NOT OVERFILL!

HT2510_20

Blades

Standard blades require no periodic adjustments. Make sure all blade shoulder bolts

are tight and in good condition.

Clean blades and apply a light coating of oil to all metal surfaces. Vegetable

■

oils may be used to protect sensitive plants from spotting.

Locknut

Cutters

Socket Head

Shoulder Bolt

Plate

Guide Bar

Figure 22

Spacer

Gearcase lubrication

BOTTOM

VIEW

Grease tting

Gearcase cover

Hex screws

BOTTOM VIEW

Every 100 Hours

(or before long-term storage)

CAUTION!

Over-lubricating may cause the

■

gearcase to run slower than nor-

mal, and may also cause leakage

from excess grease.

Figure 21