ASSEMBLY

1900 07/10 Assembly Section 3-3

© 2010 Alamo Group Inc.

ASSEMBLY

TRACTOR PREPARATION

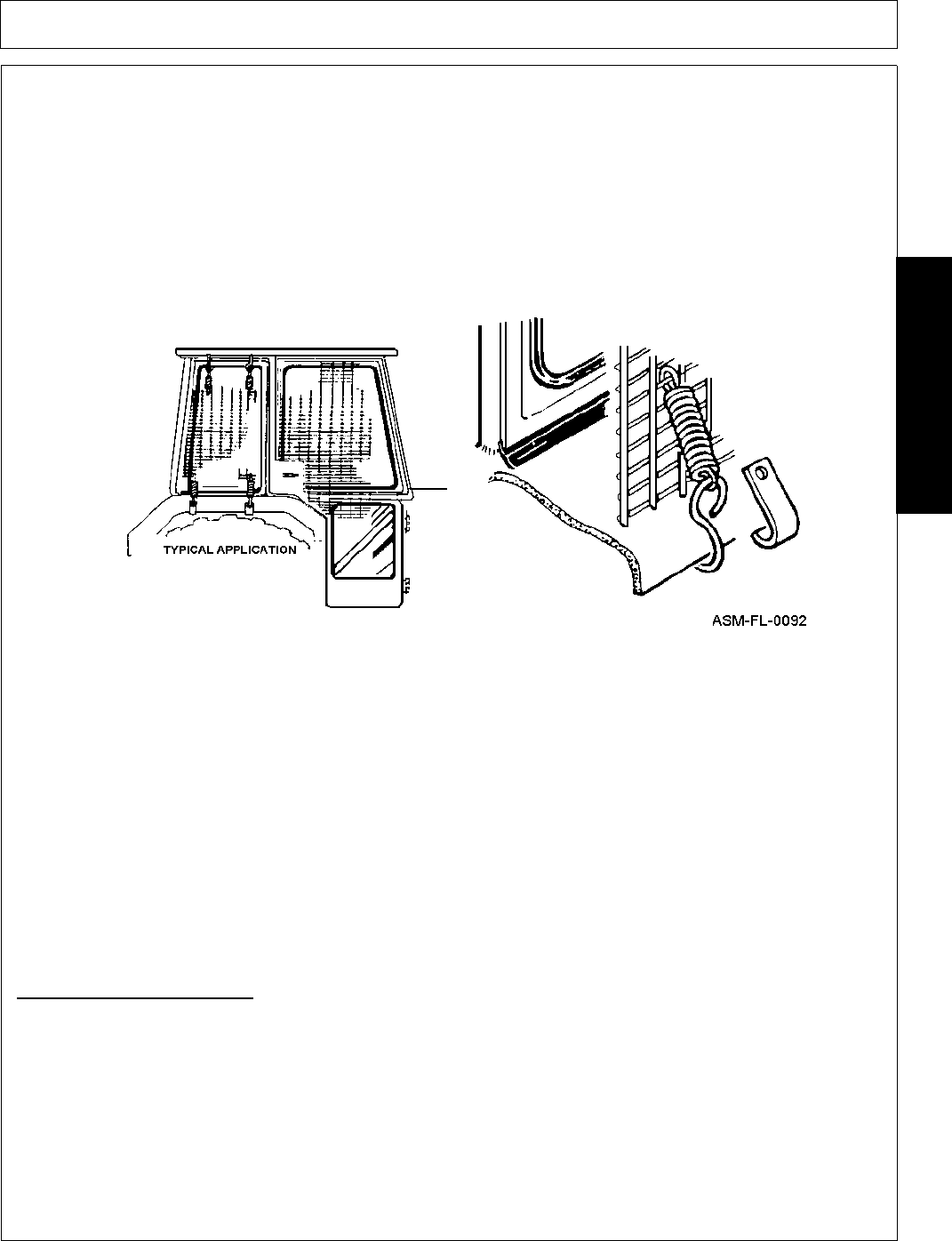

Fitting Operator Guard

Use tractor with safety glass windows if possible and fit Operator guard using the hooks provided. Shape mesh

to cover all vulnerable areas. Remember the driver must be looking through mesh and/or poly carbonate

glazing when viewing the flail head in any working position - unless the tractor/cab manufacturer can

demonstrate that the penetration resistance is equivalent to, or higher than, that provided by mesh/poly

carbonate glazing. If the tractor has a roll bar only, a frame must be made to carry both mesh and poly

carbonate glazing.

Wheel Width: Set wheel widths as wide as possible.

Lift Links: Adjust lift links until they are equal length.

Tractor Ballast: It is imperative when attaching ‘third-party’ equipment to a tractor that the maximum possible

stability of the machine and tractor combination is achieved – this can be accomplished by the utilization of

‘ballast’ in order to counter-balance the additional equipment added.

Front weights may be required to place 15% of total outfit weight on the front axle for stable transport on the

road and to reduce ‘crabbing’ due to the drag of the cutting unit when working on the ground.

Rear weights may be required to maintain a reasonable amount of rear axle load on the opposite wheel from

the arms when in work; for normal off-ground work i.e. hedge cutting this should be 20% of rear axle weight or

more for adequate control, and for ground work i.e. verge mowing with experienced operators, this can be

reduced to 10%. All factors must be addressed in order to match the type and nature of the equipment added

to the circumstances under which it will be used – in the instance of Power Arm Hedge cutters it must be

remembered that the machines centre of gravity during work will be constantly moving and will differ from that

during transport mode, therefore balance becomes critical.

Factors that effect stability:

• Centre of gravity of the tractor/machine combination.

• Geometric conditions, e.g. position of the cutting head and ballast.

• Weight, track width and wheelbase of the tractor.

• Acceleration, braking, turning and the relative position of the cutting head during these

• operations.

• Ground conditions, e.g. slope, grip, load capability of the soil/surface.

• Rigidity of implement mounting.