carburetor

adiustment

CAUT

ION:

WHEN

FOLLOWING

STEPS

1

THRU

5

BELOW,

USE

EXTREME

CARE

TO

AVOID

CONTACT

WITH

MUFFLER,

HEAT

SHIELD

OR

MOVING

PARTS

TO

PREVENT

INJURY.

ALSO,

BELT

GUARD

MUST

BE

IN

PLACE.

MAIN

FUEL

AND

IDLE VALVE

ADJUSTMENT

LOW

SPEED

SET

ON

GOVERNOR

LlNKAGE-

SMALL

GAP

HERE

AT

NO

LOAD

MAIN

FUEL

(HIGH

SPEED)

ADJUSTMENT

THROTTLE

IDLE

STOP

ADJUSTMENT

SCREW

SIDE

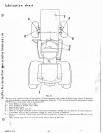

VIEW

FIG.21

INITIAL

ADJUSTMENT:

REAR

VIEW

The

carburetor

has

a

main

fuel

valve

adiusting

screw

and

an

idle

valve

adjusting

screw.

(Fig.

21).

A

low

speed

adjustment

screw

is

shown

in

(Fig.

22).

1.

Turn

main

fuel

valve

clockwise

until

it

just

closes.

CAUTION:

Valves

may

be

damaged

by

turning

then

in

too

far.

2.

Now

open

main

fuel

valve

1

turn

counterclockwise.

3.

Close

idle

valve

in

same

manner

and

open

it

5/8

turn

(counterclockwise).

4.

Thi

s

initial

adjustment

wi

II

permit

engine

to

start

and

warm

up

prior

to

final

adjustment.

FINAL

ADJUSTMENT

1.

Turn

main

fuel

valve

in

until

engine

misses

(lean

mixture),

than

turn

it

out

past

the

point

where

en·

~ine

runs

smoothly

until

engine

runs

unevenly

(rich

mixture).

Turn

valve

to

mid·point

between

I

ean

and

ri

ch

so

eng

i ne

runs

smooth

Iy.

2.

Hold

engine

at

idle

position

and

set

low

speed

adjustment

screw

(Fig.

22)

until

a

fast

idle

is

obtained

(1200

rpm).

3.

Hold

throttle

in

idle

position

and

turn

idle

adjust·

ment

valve

in

(lean)

and

out

(rich)

until

engine

idles

smoothly.

4.

Reset

low

speed

adjustment

screw

so

engine

idles

at

1200

rpm.

5.

Re

lease

thrott

le·eng

i

ne

shou Id

acce

lerate

without

hesitation.

If

engine

does

not

accelerate

properly,

readjust

main

fuel

valve

by

turning

out

slightly.

IMPORT

ANT:

Do

not

open

more

than

Y2

turn

be-

yond

maximum

power

point.

LOW

SPEED

ADJUSl

MENT

0©J~===-=Q.m

.........

-

o 1

__

-

SET

LOW

SPEED

ADJUSTMENT

SO

ENGINE

RUNS

AT

1200

RPM

IN

"SLOW"

POSITION.

~

4824R·7. 1.74

FIG.

22

spark

FIG.

23

SPARK

PLUG

GAP

0.025"

GASOLINE

SPARK

PLUGS:

Check,

clean

and

reset

spark

plugs

every

100

operating

hours.

Replace

spark

plugs

that

show

signs

of

fouling

or

electrode

erosion

.

. 025

(cold)

BREAKER

POINTS:

Check,

clean

and

reset

breaker

points

every

200

operating

hours.

Replace

points

if

they

are

pitted

or

burned.

Set

point

gap

to

.025

cold

when

fu

Ily

open.

tire

s

air

pressure

in

tires.

G

--'-+-'--11

To

remoy.£,

a

front

tire

and

wheel,

proceed

as

fol·

lows:

1.

Block

up

Tractor

rocker

bar

(front

axle)

securely

or

use

a

Sears

Tractor

Jack.

2.

Remove

hex

bolt

(A),

and

dust

cap

(8).

3.

Remove

gripco

nut

(C),

wear

washer

(D),

pin

(E),

and

washer

(F),

from

spindle

shaft

as·

sembly

(G).

4.

After

tire

is

repaired,

reverse

above

procedure

for

reassembly.

A

rear

whee

I and

tire

is

removed

by

remov

i ng

the

five

hub

bolts

from

wheel

and

hub.

FI

RST:

Block

up

rear

axle

securely

or

use

a Sears

Tractor

Jack.

Sears

or

your

local

service

station

can

repair

your

Tractor

tire

in

the

same

manner

as

an

automobile

•

12.

tire.

another free manual from www.searstractormanuals.com