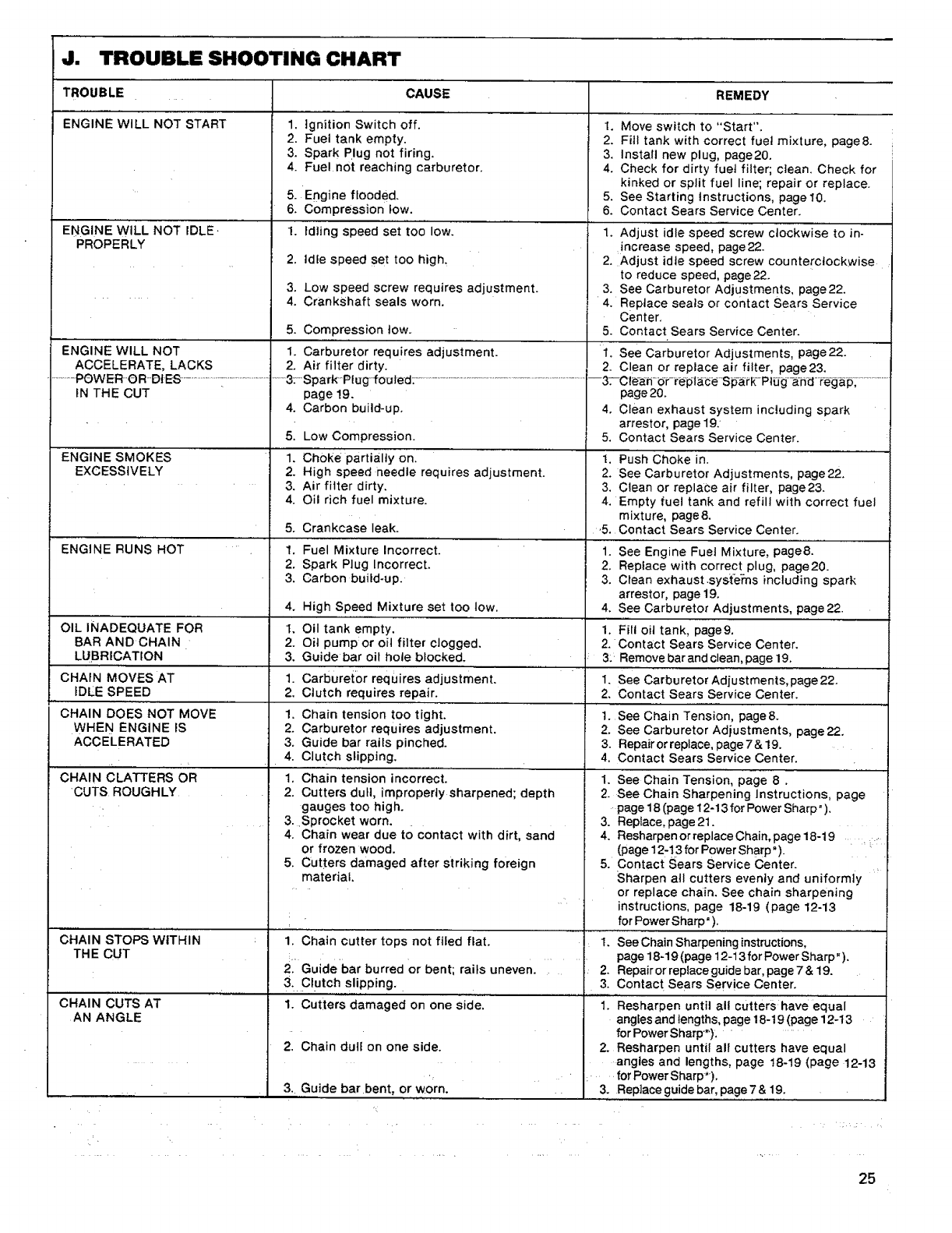

J. TROUBLE SHOOTING CHART

TROUBLE CAUSE REMEDY

ENGINE WILL NOT START

EI_GINE'WlLL NOT IDLE-

PROPERLY

1. ignition Switch off.

2. Fuel tank empty.

3. Spark Plug not firing.

4. Fuel n0t reaching carburetor.

5. Engine flooded.

6. Compression low.

1. Idling speed set too low.

2.

3.

4.

5.

Idle speed set too high.

Low speed screw requires adjustment.

Crankshaft seals worn.

Compression tow.

ENGINE WILL NOT I. Carburetor requires adjustment. 1. See Carburetor Adjustments, page22.'

ACCELERATE, LACKS 2. Air filter dirty. 2. Clean or replace air filter, page23.

1. Move switch to "Start".

2. Fill tank with correct fuel mixture, page8.

3. Install new plug, page20.

4. Check for dirty fuel filter; ciean. Check for

kinked or split fuel line; repair or replace.

5. See Starting Instructions, page10.

6. Contact Sears Service Center.

1. Adjust idle speed'"screw clockwise' to in-

increase speed, page 22.

2. Adjust idle speed screw counterclockw se

to reduce speed, page22.

3. See Carburetor Adjustments, page22.

4. Replace seals or contact Sears Service

Center.

5. Contact Sears Service Center.

............POWEROR--DfES ...............................................................3:-Spark Plugffouted: ...........................................................................................................3:-Cre-ati-dt-repladeSp-atk--PtfJ-g_-hd-f'-e-g_p; ..............

IN THE CUT page 19. page20.

ENGINE SMOKES

EXCESSIVELY

ENGINE RUN'S'HOT

i......................

OIL INADEQUATE FOR

BAR AND CHAIN

LUBRICATION

CHAIN MOVES AT

IDLE SPEED

CHAIN DOES NOT MOVE

WHEN ENGINE IS

ACCELERATED

CHAIN CLATTERS OR

'CUTS ROUGH LY

CHAIN STOPS Wi"T'HIN

THE CUT

4. Carbon build-up.

CHAIN CUTS AT

AN ANGLE

5.

2.

• 3,

4.

5.

2.

3.

4.

I.

2.

3.

1.

2.

Low Compression.

Choke partially on.

High speed needle requires adjustment.

Air filter dirty.

Oil rich fuel mixture. 4.

Crankcase leak. ,5.

Fuel Mixture Incorrect. 1.

Spark Plug Incorrect. 2.

Carbon build-up. 3.

High Speed Mixture set too low.

Oil tank empty.

Oi! pump:or oil filter clogged.

Guide bar oil hole blocked.

Carburetor requires adjustment.

Clutch requires repair.

1. Chain tension too tight.

2. Carburetor requires adjustment.

3. Guide bar rails pinched.

4. Clutch slipping.

1. Chain tension incorrect.

2. Cutters dull, improperly sharpened; depth

gauges too high.

3. Sprocket worn.

4. Chain wear due to Contact with dirt, Sand

or frozen wood.

5. Cutters damaged after striking foreign

material.

1. Chain cutter tops not filed flat. I

21 Guidebar burred or bent; rails uneven.

3_ Clutch slipping,

1. Cutters damaged on one Side.

2. Chain dull on one side.

3. Guide bar bent, or worn.

4. Clean exhaust system including spark

arrestor, page 19:

5. Contact Sears Service Center.

1. Push Choke in.

2. See Carburetor Adjustments, page22.

3. Ctean or replace air filter, page23.

Empty fuel tank and refill with correct fuel

mixture, page&

Contact Sears Service Center.

See Engine Fuel Mixture, page8.

Replace with correct plug, page20.

Clean exhaust.sys:tehns including spark

arrestor, page 19.

4. See Carburetor Adjustments, page 22.

1. Fill oil tank, page9.

2. Contact Sears Service Center.

3: Remove barand clean, page 19.

1. See Carburetor Adjustments, page22.

2. Contact Sears Service Center.

1. See Chain Tension, page8.

2. See Carburetor Adjustments, page 22.

3. Repair or replace, page 7 & 19.

4. Contact Sears Service Center.

1. See Chain Tension, page 8 . '............

2. See Chain Sharpening Instructions, page

page 18 (page 12-13 for Power Sharp "),

3. Replace, page 21.

4. Resharpen or replace Chain, page 18-19

(page 12-!.3 for Power Sharp").

5. Contact Sears Service Center.

Sharpen n!l cutters evenly and uniformly

or replace chain. See chain sharpening

instructions, page 18-19 (page 12-13

for Power Sharp" ).

1. See Chain Sharpening instructions,

page 18-19 (page 12-13 for Power Sharp ").

2. Repair or replace guide bar, page 7 & 19.

3. Contact Sears Service Center.

1. Resharpen until all cutters have equal

angles and lengths, page 18-19 (page 12-13

for Power Sharp''). ........

2. Resharpen until all cutters have equal

angles and lengths, page 18-19 (page 12-13

: . for Power Sharp").

3. Replace guide bar, page 7 & 19.

25