29

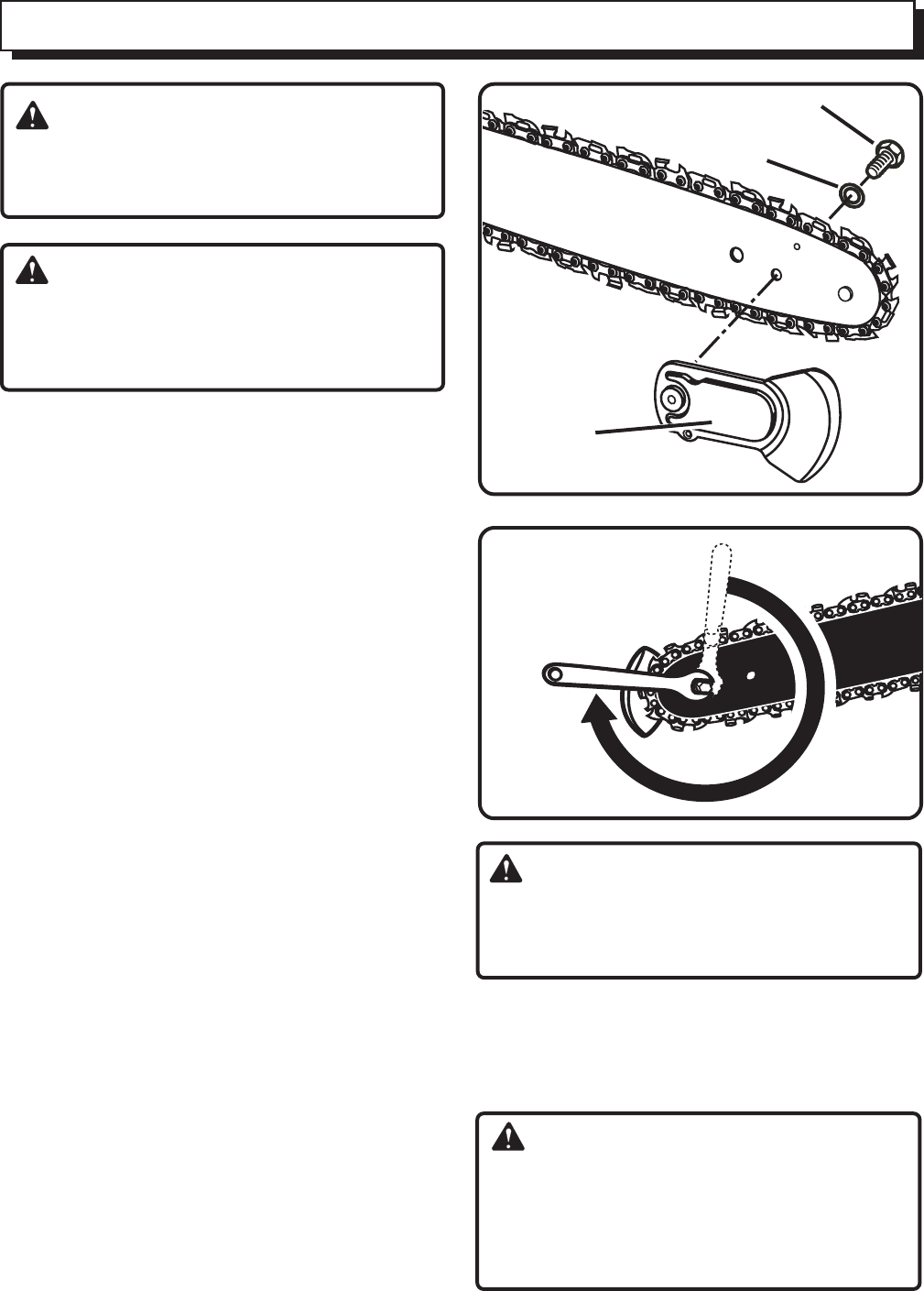

SAFE-T-TIP® NOSE GUARD MAINTE-

NANCE

See Figures 42 and 43.

Tighten the mounting screw of the nose guard as

instructed below. These are specially hardened

screws. If the screw cannot be installed tightly, replace

both the screw and the SAFE-T-TIP® before further

operation. Do not replace with an ordinary screw.

In addition to preventing chain contact with solid

objects at the nose of the bar, the SAFE-T-TIP® also

helps keep the chain away from abrasive surfaces

such as the ground. Keep it on the right hand side of

the bar, where it will be between the chain and the

ground during flush with ground cutting.

The mounting screw requires a 5/16 in. wrench (or

adjustable wrench) to achieve the recommended

tightness of 35 to 45 in. lb. (4-5 Nm). A tightness

within this range can be achieved by the following

method.

1. Tighten the screw with your finger.

2. From the finger-tight position, tighten the screw an

additional 3/4 of a turn using a wrench.

MOUNTING SAFE-T-TIP® NOSE GUARD

See Figuress 42 and 43.

1Mount the SAFE-T-TIP® on the bar nose.

NOTE: The tab fits in the recessed hole in the bar.

2. Tighten the screw with your finger.

3. From the finger-tight position, tighten the screw an

additional 3/4 of a turn using a wrench.

WARNING:

Although the guide bar comes with a SAFE-T-

TIP® anti-kickback device already installed, you

need to check the tightness of the mounting

screw before each use.

TIGHTEN 3/4

OF A TURN

MOUNTING SCREW

SAFE-T-TIP

LOCKING RIVET

CAUTION:

Remove the battery pack and make sure the

chain has stopped before you do any work on

the saw.

Fig. 42

Fig. 43

MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types

of commercial solvents and may be damaged by their

use. Use clean cloths to remove dirt, dust, oil, grease,

etc.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.

come in contact with plastic parts. They contain

chemicals that can damage, weaken or destroy

plastic.

WARNING:

When servicing use only identical Ryobi

replacement parts. Use of any other parts may

create a hazard or cause product damage.