23

INSTALLING STRING IN PRO CUT II STRING

HEAD

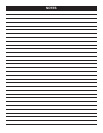

See Figure 29.

Use monofilament string between .095 in. and .105 in. di-

ameter. Use original manufacturer’s replacement string for

best performance.

Stop the engine and disconnect the spark plug wire.

Gather two of the pre-cut lengths of trimmer line provided

or cut two pieces of trimmer line, in 11 in. lengths.

Insert the strings into the slots located on the sides of

the string head. String should be pushed in until approxi-

mately 1 in. protrudes from the holes on the top of the

string head.

Remove old string by pulling it from the holes located on

the top of the string head.

CLEANING THE EXHAUST PORT AND

MUFFLER

NOTE: Depending on the type of fuel used, the type and

amount of lubricant used, and/or your operating conditions, the

exhaust port, muffler, and/or spark arrestor screen may

become blocked with carbon deposits. If you notice a

power loss with your gas powered tool, you may need to

remove these deposits to restore performance. We highly

recommend that only qualified service technicians perform

this service.

SPARK ARRESTOR

The spark arrestor must be cleaned or replaced every 50

hours or yearly to ensure proper performance of your prod-

uct. Spark arrestors may be in different locations depending

on the model purchased. Please contact your nearest service

dealer for the location of the spark arrestor for your model.

IDLE SPEED ADJUSTMENT

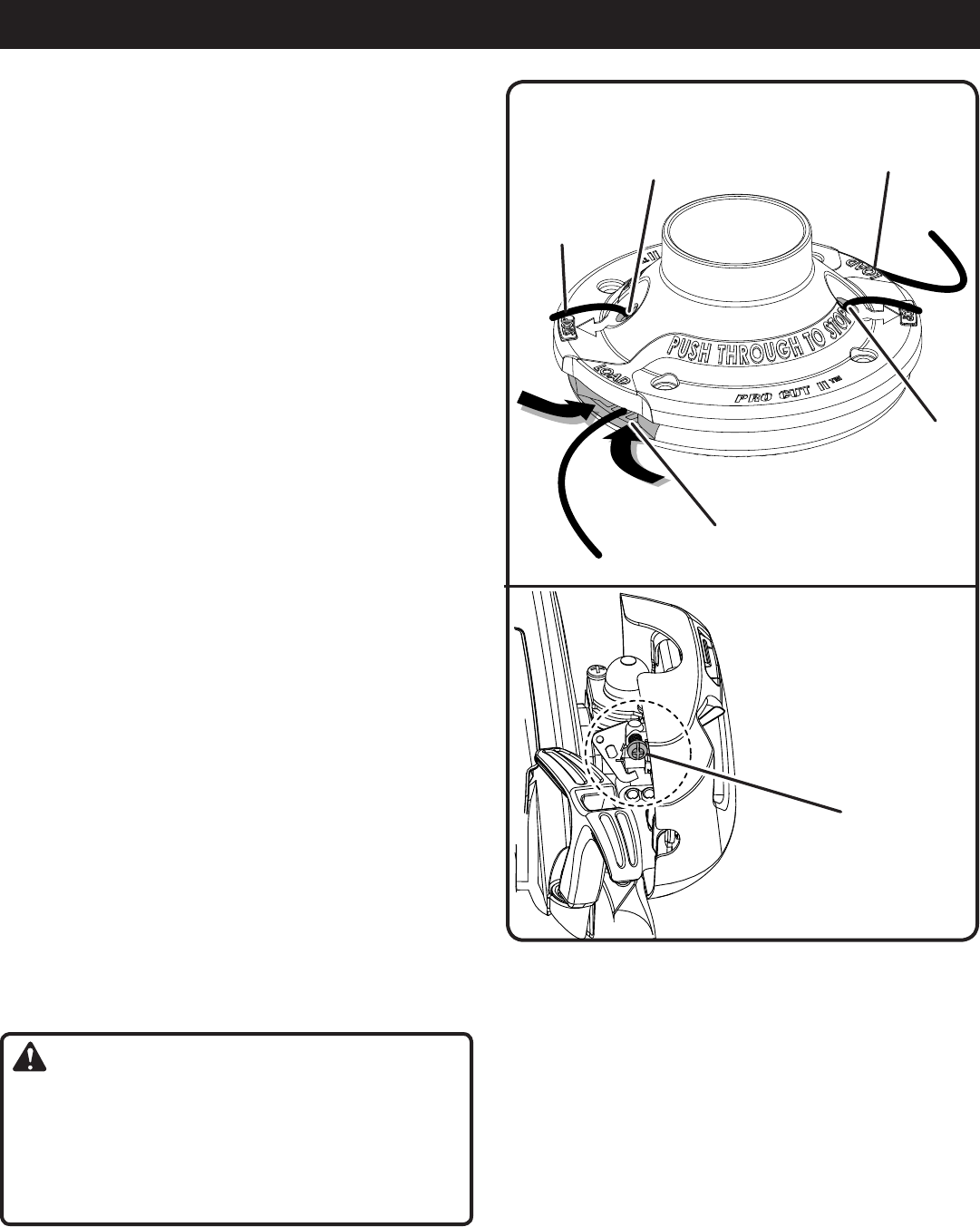

See Figure 30.

If the cutting attachment turns at idle, the idle speed screw

needs adjusting on the engine. Turn the idle speed screw

counterclockwise to reduce the idle RPM and stop the cut-

ting attachment movement. If the cutting attachment still

moves at idle speed, contact a service dealer for adjustment

and discontinue use until the repair is made.

WARNING:

The cutting attachment should never turn at idle. Turn

the idle speed screw counterclockwise to reduce the

idle RPM and stop the cutting attachment, or contact a

service dealer for adjustment and discontinue use until

the repair is made. Serious personal injury may result from

the cutting attachment turning at idle.

MAINTENANCE

Fig. 29

HOLE

SLOT

SLOT

INSERT STRINGS THROUGH SLOTS UNTIL

APPROX. 1 IN. PROTRUDES FROM HOLES

HOLE

PULL STRINGS

FROM HOLES

TO REMOVE

Fig. 30

IDLE

SPEED SCREW