MAINTENANCE

FN180/FN120 01/11 Maintenance Section 5-10

©2011 Alamo Group

MAINTENANCE

INTEGRAL FRICTION CLUTCH MAINTENANCE

If the clutch has not been operated for (1) season we recommend the following:

TOOLS REQUIRED: (2) 10 mm Box Wrenches

RUN - IN

(Necessary for all new clutches and any clutch which has not been used in approximately 60 days)

1. Make sure the tractor is off and the PTO is

disengaged.

2. Disconnect the drive shaft from the tractor.

3. Loosen the bolts on the outside diameter of the

clutch until all bolts are just loose, then tighten

all bolts one half turn.

4. Attach the implement to the tractor and the drive

shaft to the tractor PTO. Stand clear of the machine.

5. Turn the tractor on. Engage the PTO clutch and run for a few seconds, or until the clutch visibly smokes,

then disengage the PTO.

6. Make sure the tractor is off and the PTO is disengaged.

7. Disconnect the drive shaft from the tractor.

8. Tighten all the bolts on the outside diameter of the clutch until the spacers cannot be rotated by hand then

back off until the spacers rotate by hand.

DRIVE SHAFT REMOVAL

1. With the tractor PTO disengaged and tractor off, disconnect the drive shaft from the tractor PTO shaft.

2. Remove the bolt(s) clamping the clutch drive shaft to the implement input shaft.

3. The drive shaft with the clutch is heavy. Grasp the clutch firmly with both hands and slide it off the

implement input shaft.

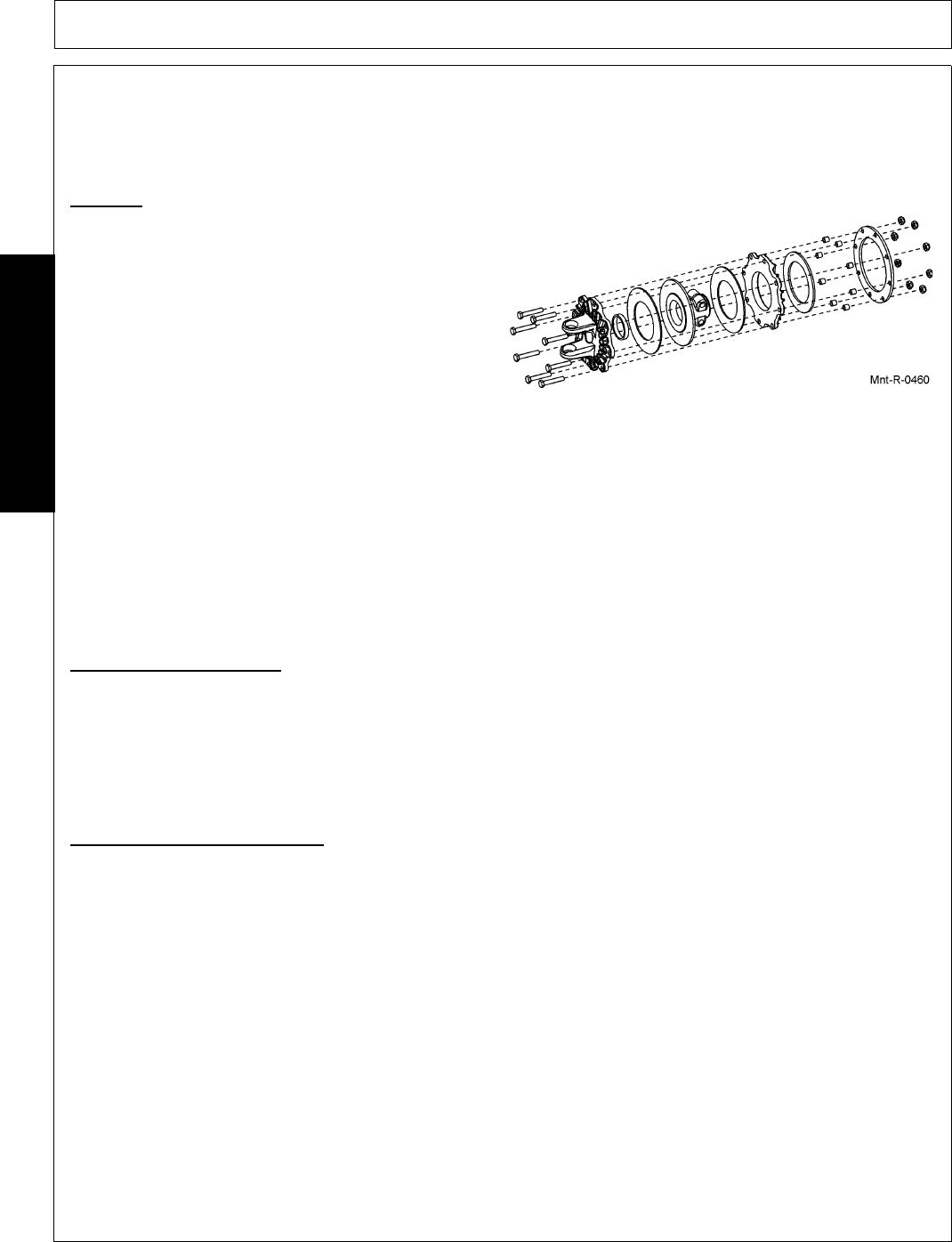

FRICTION PACK REBUILDING

DISASSEMBLY:

1. Place the clutch and universal joint assembly on a bench, with the end of the clutch accessible.

2. Remove the long bolts on the outside of the housing which hold the friction pack together.

3. Remove the plate(s) and all internal components.

4. Discard the friction discs.

INSPECTION:

5. Inspect the steel and iron parts for wear, warping or cracking and replace if necessary.

6. Clean any rust from the plate surfaces with a wire brush or steel wool.