7

7

100273

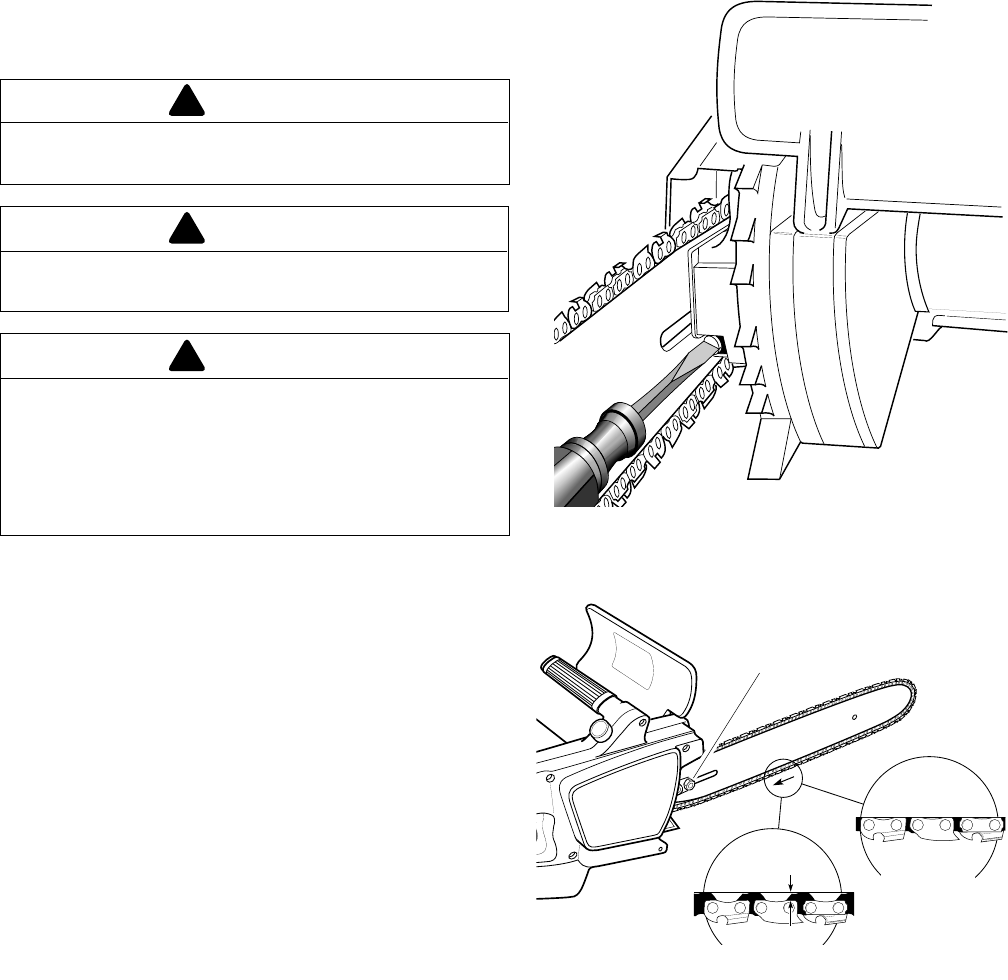

SAW CHAIN TENSION

ADJUSTMENT

Note:

For pre assembled models, the saw chain tension is

properly set at factory. A new chain will stretch. Check new

chain after first few minutes of operation. Allow chain to cool

down. Follow steps below to readjust saw chain tension.

1. Before adjusting chain, make sure guide bar nuts are only

finger tight (see Figure 3, page 6). Also make sure adjust-

ing block is in oval adjusting hole on guide bar (see Figure

3 and 4, page 6).

2. Turn adjusting screw clockwise until all slack is out of

chain (see Figure 5).

Note:

There should be no gap between side links of chain

and bottom of guide bar (see Figure 6).

3. Wearing protective gloves, move chain around guide bar.

Chain should move freely. If chain does not move freely,

loosen chain by turning adjusting screw counterclockwise.

4. After chain tension is correct, tighten guide bar nuts firmly.

If not, guide bar will move and loosen chain tension. This

will increase the risk of kickback. This can also damage

saw.

Note:

A new chain will stretch. Check new chain

after first few minutes of operation. Allow chain to cool

down. Readjust chain tension.

Figure 5 - Turning Adjusting Screw

!

WARNING ICON G 001

WARNING

Unplug chain saw from power source before

adjusting saw chain tension.

!

WARNING ICON G 001

WARNING

Cutting edges on chain are sharp. Use protective

gloves when handling chain.

!

WARNING ICON G 001

WARNING

Maintain proper chain tension always. A loose

chain will increase the risk of kickback. A loose

chain may jump out of guide bar groove. This

may injure operator and damage chain. A loose

chain will cause chain, guide bar, and sprocket

to wear rapidly.

FILLING OIL TANK

1. Remove oil cap.

2. Fill oil tank with SAE #30 motor oil.

Note:

For tempera-

tures below -1°C, use SAE #10 oil. For temperatures above

24°C, use SAE #40 oil.

3. Replace oil cap at once. Tighten oil cap firmly for good

seal. This will avoid oil seepage from tank.

4. Wipe off excess oil.

Note:

It is normal for oil to seep when saw is not in use.

Empty oil tank after each use to prevent seepage.

Guide Bar

Incorrect Tension

Figure 6 - Saw Chain Adjustment

Guide Bar

Nuts

Guide Bar

Gap

Correct

Tension