14

CLEANING

IMPORTANT: For best performance, keep snow thrower

housing free of any dirt or trash. Clean the outside of your

snow thrower after each use.

WARNING: Remove safety ignition key

and disconnect spark plug wire from

spark plug. Place wire where it can not

come in contact with spark plug.

• Keep finished surfaces/wheels free of gasoline, oil, etc.

• We do not recommend using a garden hose to clean

your snow thrower unless the electrical system, muffler

and carburetor are covered to keep water out. Water

in engine can result in shortened engine life.

MAINTENANCE

BELTS

Check belts for deterioration and wear after every 50 hours

of operation and replace if necessary. The belts are not

ad just able. Replace belts if they begin to slip from wear.

(See “TO REMOVE BELT COVER” in the Service and

Adjustments section of this manual).

The belts on your snow thrower are of special con struc tion

and should be replaced by original equipment man u fac tur er

(OEM) belts avail able from your nearest dealer. Using other

than OEM belts can cause personal injury or damage to

the snow thrower.

SNOW THROWER

Always observe the safety rules when performing any

main te nance.

TIRES

• Maintain proper air pressure in both tires (14–17 PSI).

• Keep tires free of gasoline and oil, which can harm rubber.

NOTE: To seal tire punctures and prevent flat tires due

to slow leaks, tire sealant may be purchased from your

local parts dealer. Tire sealant also prevents tire dry rot

and cor ro sion.

AUGER GEAR CASE

• The gear case was filled with lubricant to the proper level

at the factory. The only time the lubricant needs atten-

tion is if service has been performed on the gear case.

• If lubricant is required, use only Ronex ED #1 grease.

TRACTION DRIVE SYSTEM

DO NOT lubricate the drive components inside the snow

thrower. The sprockets, hex shafts, drive disc and friction

wheel require no lubrication. The bearings and bushings

are lifetime lubricated and require no maintenance.

CAUTION: Any lubricating of the above com po-

nents can cause contamination of the friction

wheel and damage to the drive system of your

snow thrower.

ENGINE

See engine manual.

LUBRICATION

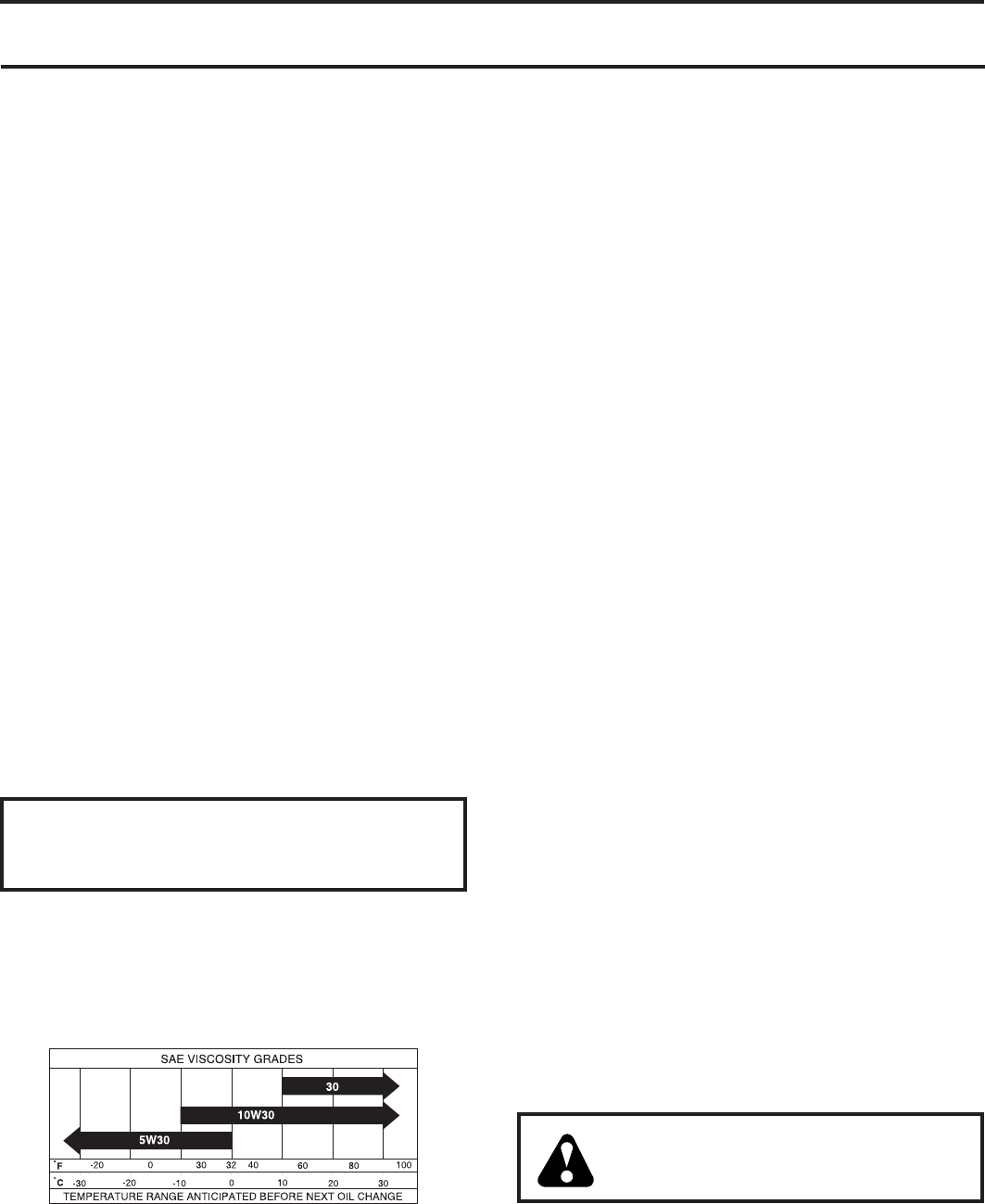

Use only high quality detergent oil rated with API service

classification SG–SL. Select the oil's SAE viscosity grade

according to your expected operating temperature.

NOTE: Although multi-viscosity oils (5W30, 10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F. Check your engine oil level more frequently to avoid

possible engine damage from running low on oil.

Change the oil after every 25 hours of operation or at least once

a year if the snow thrower is not used for 25 hours in one year.

MUFFLER

Inspect and replace corroded muffler as it could cre ate a

fire haz ard and/or dam age.

SPARK PLUG

Replace spark plug at the beginning of each season or after

every 100 hours of operation, whichever occurs first. Spark

plug type and gap setting are shown in the “PROD UCT

SPEC I FI CA TIONS” section of this manual.

Check the crankcase oil level before starting the engine

and after each five (5) hours of continuous use. Tighten oil

fill cap / dipstick securely each time you check the oil level.

TO CHANGE ENGINE OIL

Determine temperature range anticipated before next oil

change. All oil must meet API service classification SG–SL.

• Be sure snow thrower is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

NOTE: A wheel may be removed from snow thrower for

easier access to the oil drain plug and place ment of a

suitable container.

1. Remove safety ignition key and disconnect spark plug

wire from spark plug. Place wire where it cannot come

in contact with spark plug.

2. Clean area around drain plug.

3. Remove drain plug and drain oil in a suitable container.

4. Install drain plug and tighten securely.

5. Wipe off any spilled oil from snow thrower and engine.

6. Install left wheel (if removed for draining oil). Be sure

to install wheel pin and retainer pin into proper hole

in wheel axle (See “TO REMOVE WHEELS” in the

Service and Adjustments section of this manual).

7. Remove oil fill cap/dipstick. Be careful not to allow dirt

to enter the engine.

8. Refill engine with oil through oil dipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

“PRODUCT SPECIFICATIONS” section of this man u al.

9. Use gauge on oil fill cap/dipstick for checking level.

Be sure dipstick cap is tightened securely for accurate

reading. Keep oil at “FULL” line on dipstick.

10. Wipe off any spilled oil.