15

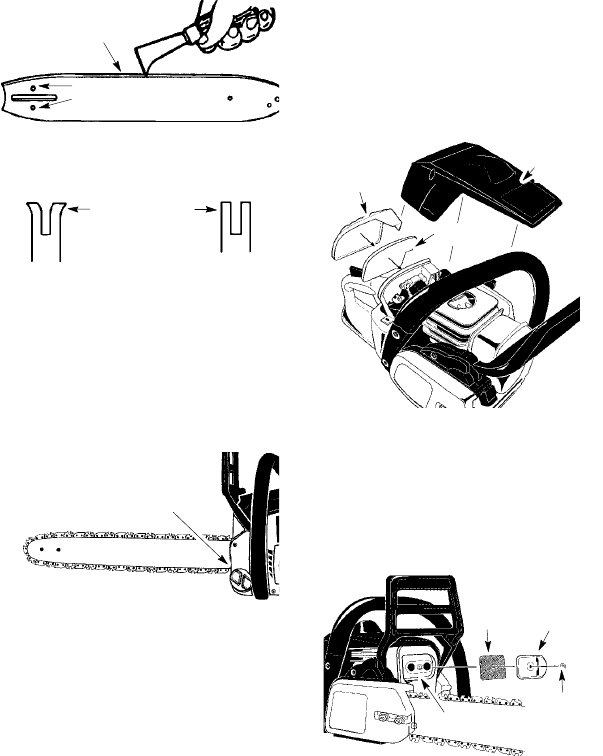

S Clean the oil holes and bar groove after

each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal

process of rail w ear. Remove these burrs

with a flat file.

S When railtop is uneven, usea flatfile tore-

store square edges and sides.

Correct GrooveWorn G roove

File Rail Edges

and Sides

Square

Replace guide bar when the groove is worn,

the guide bar is bent or cracked, or when ex-

cess heating or burring of the rails occurs. If re-

placement is necessary , use only the guide bar

specified for your saw i n t he repair par ts list or

on the decal located on the chain saw .

CHECK FUEL MIXTURE LEVEL

S See FUELING ENGINE under the OP-

ERA TION section.

LUBRICATION

Bar Oil

Fill Cap

S See GUIDE BAR AND CHAIN OIL under

the OPERA TION section.

INSPECT AND CLEAN UNIT AND

DECALS

S After each use, inspect complete unit for

loose or damaged parts. Clean the unit and

decals using a damp cloth with a mild deter-

gent.

S Wipe off unit with a c lean dry cloth.

CHECK CHAIN BRAKE

See CHAIN BRAKE in the OPERATION

section.

CLEAN AIR FILTER

CAUTION:

Donotcleanfilterin gasolineor

other flammable solvent to avoid creating a

fire hazard o rproducing harmfulevaporative

emissions.

Cleaning the air filter:

A dirty airfilter decreases the life and perfor-

mance of the engine andincreases fuelcon-

sumption and harmful emissions. Always

clean your air filter after 1 0 tanks of fuel or 5

hours of operation, whichever comes first.

Clean more frequently industy conditions.A

used air filter can never be completely

cleaned. It is adv isable to replace your air fil-

ter witha new oneafterevery 50hours ofop-

eration, or annually, w hichever comes first.

1. Loosen 3 screws on cylinder cover.

2. Remove cylinder cover.

3. Remove air filter cover and air filter.

4. Cleanthe airfilter usinghot soapy water.

Rinsewithcleancoolwater.Air drycom-

pletely before reinstalling.

5. Reinstall air filter and air filter cover.

6. Reinstall cylinder cover and 3 screws.

Tighten securely.

Air Filter

Air Filter

Cover

Cylinder

Cover

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

As the unit is used, carbon deposits buildup

on the muffler and spark arresting screen,

and must be removed to avoid creating afire

hazard or affecting engine performance.

Replacethe spark arresting screen ifbreaks

occur.

Nut

Exhaust

Outlet

Cover

Muffler

Spark

Arresting

Scree n

CLEANING THE SPARK ARREST-

ING SCREEN

Cleaning is required every 25 hours of op-

eration or annually, whichever comes first.

1. Loosen and remove the nut from the ex-

haust outlet cover.

2. Remove the exhaust oulet cover .

3. Removespark arrestingscreen. Handle

screen carefully to prevent damag e.

4. Clean the spark arresting screen gently

with a wire brush. Replace screen if

breaks a re found.

5. Replace any broken or cracked muffler

parts.

6. Reinstall spark arresting screen, exhaust

outlet cover , and nut. Tighten nutsecurely.