6

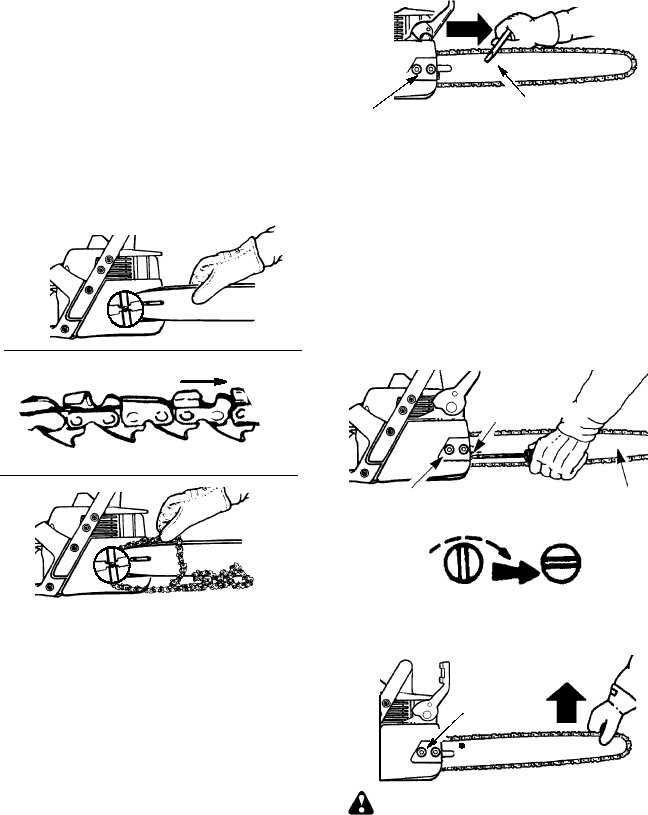

Fit the chain between the teeth in the

sprocket.

S

Start at the top of the bar and fit chain into

groove around the guide bar.

S

Pull the bar forward until the chain i s snug

in the groove of the bar.

S

Hold guide bar against the saw frame and

install the chain brake. Make s ure the ad-

justing pin is aligned with the hole i n the

bar. Remember this pin moves thebar for-

wardandbackward a sthescrewisturned.

S

Replace the chain brake nuts and tighten

finger tight. Once the chain is tensioned

you will need to tighten chain brake nuts.

Mount the Bar

Proper chain direction

Tip of B ar

Place chain onto the s

p

rocket

CHAIN TENSION

(Including units with chain already installed)

NOTE:

When adjusting chain tension,

make sure the chain brake nuts are finger

tight only. Attempting to tension the chain

when the chain brake nuts are tight can

cause damage.

Checking the tension:

Use the screwdriver endof the chain adjust-

ment tool (bar tool) tomovethe chain around

the bar. If the chain does not rotate, it is too

tight. Iftoo loose, thechain will sagbelowthe

bar.

Chain Brake Nuts

Chain Adjustment

Tool (Bar Tool)

Adjusting the tension:

Chain tension is very important. Chain

stretches during use. This is especially true

during the first few times you use your saw.

Always check chain tension each time you

use and refuel your saw.

You can adjust the chain tension by loosen-

ing the chain brake nuts and turning the ad-

justing screw 1/4 of a turn while lifting up on

the bar.

S

If chain is too tight, turn adjusting

screw 1/4 turn counterclockwise.

S

If chain is too loose, turn adjusting

screw 1/4 turn clockwise.

Adjusting

Screw

Chain Brake Nuts

Guide Bar

Adjusting Screw -- 1/4 Turn

S

Lift up the tip of the bar and tighten the

chain brake nuts with t he bar tool. Torque

to 10--15 ft/lbs.

S

Recheck chain tension.

Chain Brake

Nuts

WARNING:

If the saw is operated

with a loose chain, the chain could jump o ff

the guide bar and result in serious injury.