8

GROUNDING - All units must be grounded. Drive

a 3/4” or 1” copper pipe or rod into the ground close to

the generator. The pipe/rod must penetrate moist

earth. Connect an approved ground clamp to the pipe.

Run a 10 gauge wire from the clamp to the generator

ground screw. Do not connect to a water pipe or a

ground used by a radio system.

OPERATING SPEED

The generator must be run at the correct speed in

order to produce the proper electrical voltage and

frequency.

The output voltage should be checked to ensure

the generator is working properly subsequent to

connecting a load to the generator. Failure to do so

could result in damage to equipment plugged into the

unit and possible injury to the individual.

All engines have a tendency to slow down when a

load is applied. When the electrical load is connected

to the generator, the engine is more heavily loaded,

and as a result the speed drops slightly. This slight

decrease in speed, together with the voltage drop

within the generator itself, results in a slightly lower

voltage when the generator is loaded to its full capacity

than when it is running with no load. The slight

variation has no appreciable effect in the operation of

motors, lights and most appliances. Electronic

equipment and clocks will be effected if correct RPM is

not maintained. See Load vs. Output chart

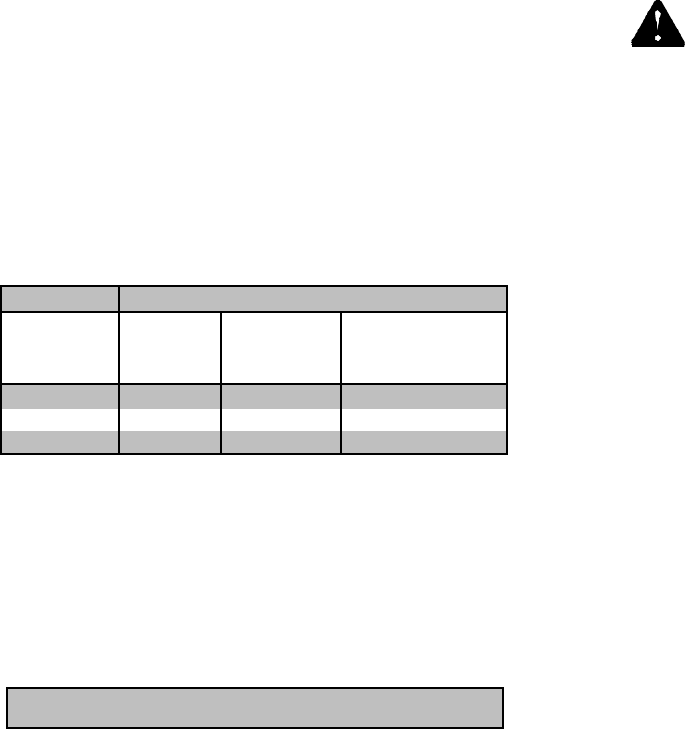

Load Output

Percent of

Generator

Output

Speed

(RPM)

Frequency

(Hz)

Generator

voltage at 120V

Receptacle

0 % 3780 63.0 125V

50 % 3600 60.0 122V

100 % 3480 58.0 118V

Output voltage should be checked periodically to

ensure continued proper operation of the generating

plant and appliances, it can be checked with a portable

meter. Frequency can be checked by using an electric

clock with a sweep second hand. Timed against a

wrist watch or a stop watch the clock should be correct

within +/- 2 seconds per minute. All speed setting

adjustments should be done by a qualified technician.

GENERATOR CARE

The generator head is a two pole, 3600 RPM, 60

Hz, brushless, revolving field and synchronous type

with two sealed radial roller bearings.

Proper care and maintenance are necessary to

ensure a long trouble free life.

Exercising The Generator - The generator

should be operated every four weeks.. This is

accomplished by starting the engine and applying a

load for 10 to 15 minutes. This will dry out any

moisture that has accumulated in the windings. If left,

this moisture can cause corrosion in the winding.

Frequent operation of the generator will also ensure

that the set is operating properly should it be needed

in an emergency.

Generator Maintenance - The generator head is

brushless and maintenance free. Any major generator

service including the installation or replacement of

parts should be performed only by a qualified electrical

service technician. USE ONLY NorthStar APPROVED

REPAIR PARTS AVAILABLE AT 1-800-270-0810.

A. Bearing - The bearings used in this generator

are a heavy duty, sealed ball bearing type. They

require no maintenance or lubrication.

B. Receptacles - Quality receptacles have been

utilized. If a receptacle should become cracked or

otherwise damaged, replace it. Using cracked or

damaged receptacles can be both dangerous to the

operator and destructive to the equipment.

WARNING, Stand-by Operation

If your generator is to be used as a standby

electric power source in case of utility failure, it must

be installed by a registered and licensed electrician

and in compliance with all applicable state and local

electrical codes. Also, local Fire Departments must be

consulted concerning proper and safe handling

procedures for gasoline. NEVER connect any

generator to any existing electrical system without an

isolating, UL approved transfer switch, installed by a

licensed electrician.