6

Tighten or loosen belt until:

d = 0.016 X L

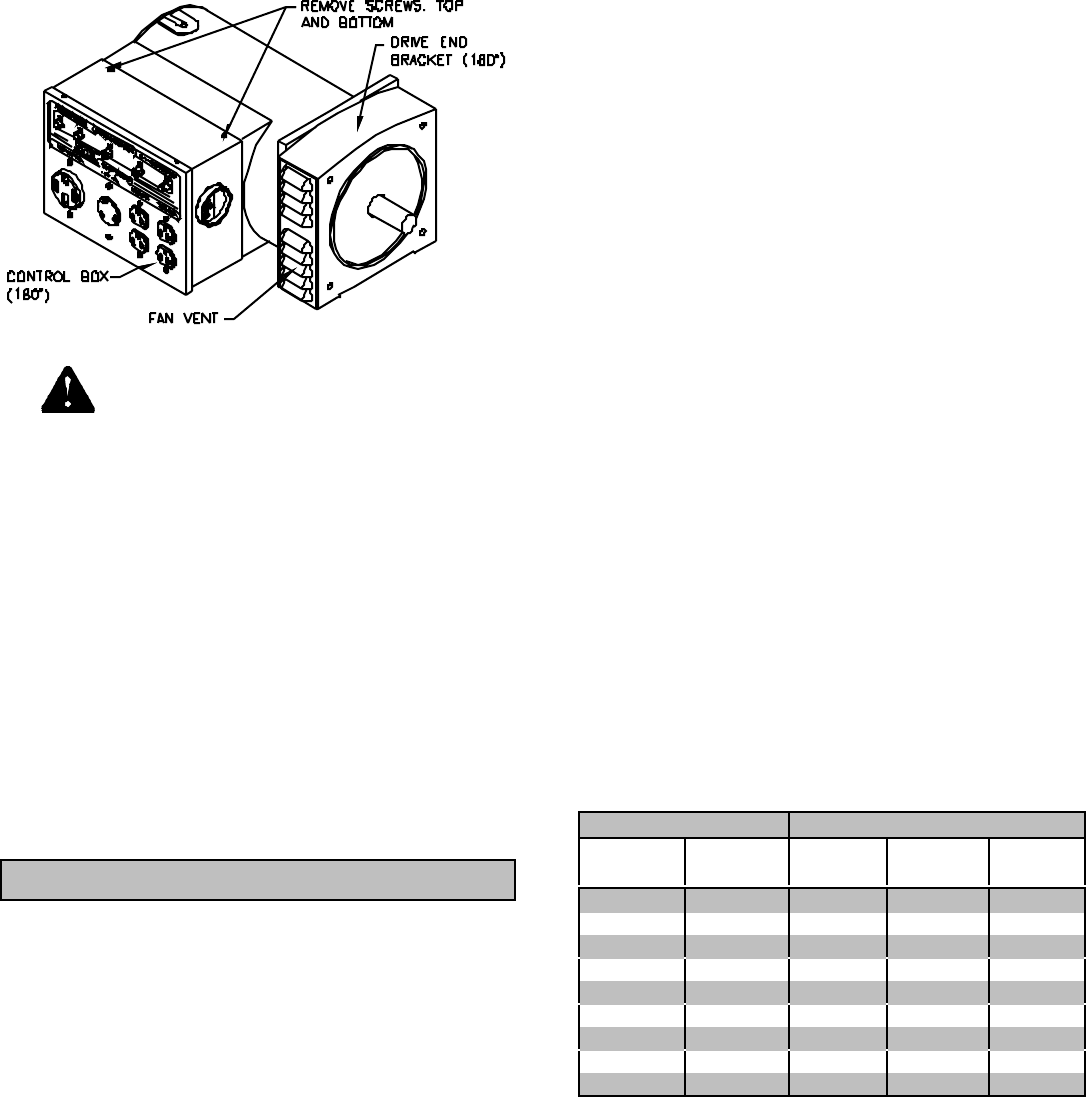

If the control box is not located on the correct

side for your application, it can be rotated to the

opposite side. First remove the fan vents, than

remove the four drive end bracket bolts. Rotate the

drive end bracket 180°, re-torque bolts to 17 ft•lb.

Reinstall the fan vents. Remove the four screws at the

base of control box, rotate the control box 180°. The

voltmeter is now on the back of the machine instead of

the front. See below for terminology.

DANGER Remember, exhaust fumes are

deadly carbon monoxide gas, and must be vented to

the outside where there are no people. Cooling air of

sufficient amounts must be brought in and exhausted

out to ensure proper cooling of the engine and

generator.

If you desire to direct couple the generator to an

engine, great care must be taken to align the shaft of

the generator and engine to within the specified

tolerances of the chosen coupler.

NEVER install your generator inside confined

areas. Inside installation can cause health hazards or

death.

LOAD APPLICATION

It is important to determine the total electrical load

before it is connected to the generator. The two major

factors in determining the life of a generator head are:

heat build up, caused by overloading the generator

and corrosive contaminants, that attack the wiring

insulation. If the generator is overloaded, the wires

become excessively hot and cause the insulation to

break down, reducing its ability to resist corrosive

contaminants. Over time the effectiveness of the

insulation is eliminated and a dead short can result.

Always compare the generator nameplate data

with that of the equipment to be used to ensure that

watts, volts, amperage, and frequency requirements

are suitable for operating equipment. The wattage

listed on the equipment nameplate is its rated output.

However, some equipment may require three to ten

times more wattage than its rating on the nameplate,

as the wattage is influenced by the equipment

efficiency, power factor and starting system. NOTE: If

wattage is not given on equipment nameplate,

approximate wattage may be determined by

multiplying nameplate voltage by nameplate

amperage.

VOLTS X AMPS = WATTS

Example: 120V X 5A = 600W

When connecting a resistive load such as

incandescent lights, heaters or common electric power

tools, a capacity of up to the generator full rated

wattage output can be used.

When connecting a resistive-inductive load such

as a fluorescent or mercury light, transformers or

inductive coils, a capacity of up to 0.6 times the

generator’s full rated output can be used.

Always allow the generator to reach operating

speed before a load is applied.

STARTING ELECTRIC MOTORS

Electric motors require much more current (amps)

to start than to run. Some motors, particularly low cost

split-phase motors, are very hard to start and require 5

to 7 times more current to start than to run. Capacitor

motors are easier to start and usually require 2 to 4

times as much current to start than to run. Repulsion

Induction motors are the easiest to start and require

1.5 to 2.5 times as much to start than to run.

Most fractional motors take about the same

amount of current to run them whether they are of

Repulsion-Induction (RI), Capacitor (Cap), or Split-

Phase (SP) type. The following chart shows the

approximate current required to start and run various

types and sizes of 120 volt 60 cycle electric motors

under various conditions.

120V, 60 Hz Motors

Starting Amps

Hp motor Running

Watts

RI type Cap type SP type

1/6 525 7-11 9-18 16-22

1/4 700 9-15 12-23 22-32

1/3 875 11-18 14-29 26-35

1/2 1175 15-25 20-40 NA

1 1925 24-40 32-64 NA

1 1/2 2400 30-50 40-80 NA

2 2900 36-60 48-96 NA

3 4075 51-85 68-136 NA

5 6750 84-140 112-224 NA

00298