5

ALWAYS remove the spark plug or spark plug

wire before working on the engine or generator, this

prevents accidental starting.

ALWAYS provide adequate ventilation. Do not

operate generator in any enclosed or narrow space.

Engines consume oxygen and give off deadly carbon

monoxide, a poisonous gas. Improper ventilation will

cause damage to generator and possible injury to

people.

ALWAYS remove all oi l or gasoline deposits and

accumulated dirt from generator and immediate area.

Keep generator head and engine clean.

NEVER operate the generator under the following

conditions:

A. Excessive change in engine speed, slow or

fast.

B. Overheating in load connecting devices.

C. Sparking or arcs from generator.

D. Loss of electrical output.

E. Damaged receptacles.

F. Engine misfire.

G. Excessive vibration.

H. Enclosed compartments, or confined

areas.

I. Flame or smoke.

J. Rain, snow or wet conditions.

K. Operator non-attendance.

L. Without proper guarding in place.

WARNING Keep fire extinguisher close

by your generator and be familiar with how to use it.

Consult your local fire department for correct

extinguisher type.

INSTALLATION

OUTDOORS: Choose a location where the

generator will not be exposed to rain, snow or direct

sunlight. Position the generator on secure, level

ground so it will not tip or slide down a hill. Place the

generator so that the

exhaust fumes will not be

directed towards people.

The installation site

must be free from water,

moisture, or dust. All

electrical components

should be protected from

excessive moisture or

the insulation system will

deteriorate and result in

grounding or shorting out of the generating system.

Foreign matters, such as dust, dirt, sand, lint or

abrasive materials can cause damage to the generator

head and engine if allowed into the cooling system.

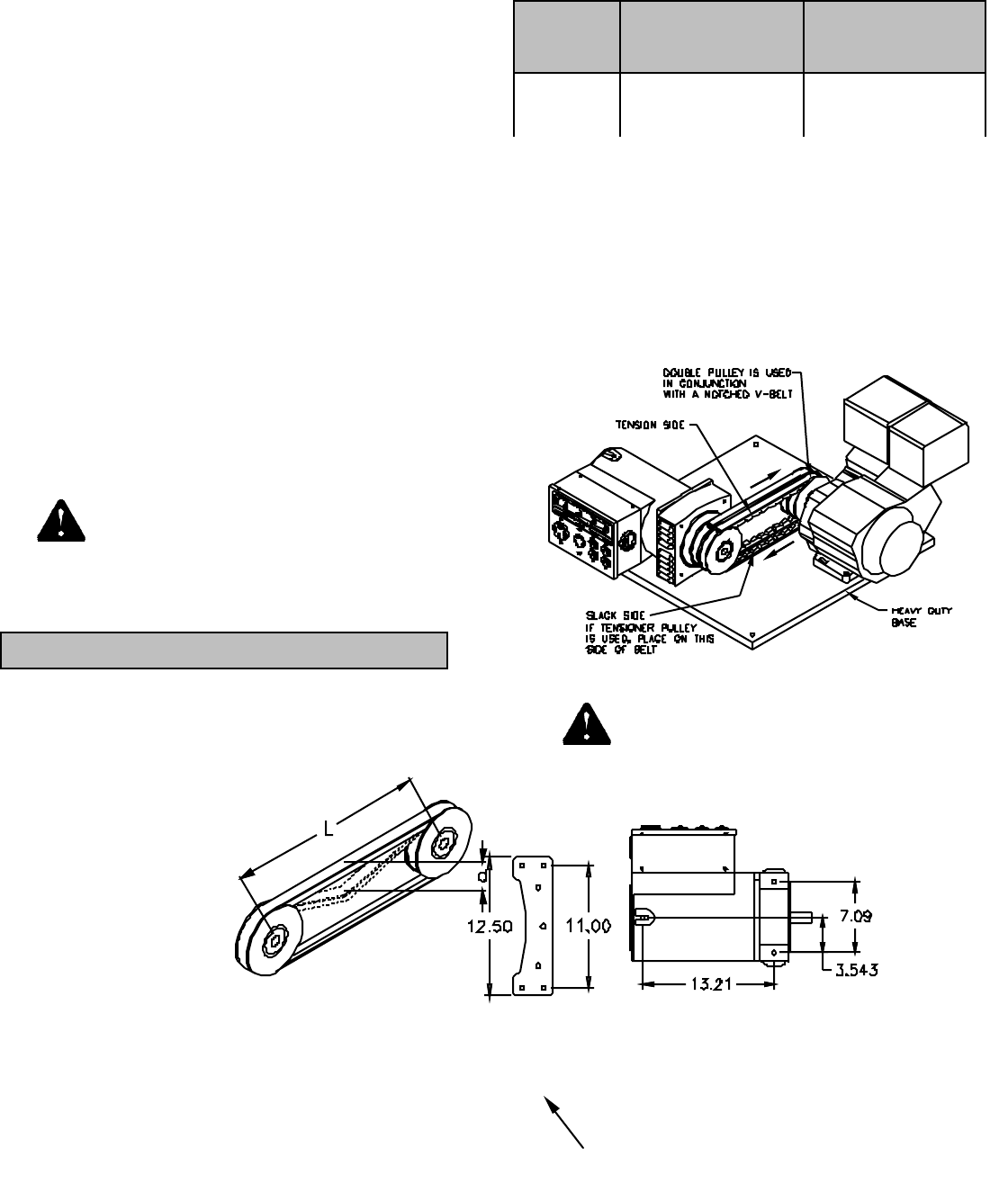

POWER TRANSMISSION: The recommended

method to transfer the power from the engine to the

generator is by using sheaves (pulleys) and a V-belt.

The generator shaft is 28 mm diameter X 2.38” long

with a 8mm key way. The table below shows the

recommended horsepower and sheaves .

The shaft speed of the generator must be between

3480-3780 RPM. At no load the correct speed is 3780

RPM. If the engine is a 3750 RPM engine, then a

sheave diameter ratio of 1:1 should be used. This

means that the diameter of the sheave on the engine

is the same as the diameter of the sheave on the

generator. If smaller than recommended sheaves are

used, the life of the belt will be shortened. The

possibility of belt slippage also increases with a

smaller sheave.

The engine and generator should be mounted to a

plate or surface that can withstand the constant

vibration and stresses that will be produced. See

figure 3 for a possible mounting configuration.

Figure 3

NOTE: Guards are removed to show details

DANGER Always have proper guarding

of the V-belt(s) and sheaves to prevent access to any

pinch points. Failure to guard the power transmission

mechanisms may result in serious injury or death.

The user shall determine the proper belt

tensioning method for their specific use.

To determine belt tension:

Measure L - the center to center distance of the two

sheaves.

Measure d - the deflection of the belt.

Engine Hp

Double Sheave Dia.

V-Belt Type

Quantity

Double Sheave Dia.

V-Belt Type

Quantity

18 Hp

6.60”

B Belt

2

6.00”

3VX Belt

2

Foot print o

f

mounting feet

is shown at left.

Use 7/16”

grade 5 bolts.

00292

00307

00039

Optional mount kit (item #165935) is available in

the Northern catalog and the NorthStar parts

catalog. Includes 2 plates and mounting hardware.

00291