8

Toaster 1000

Vacuum cleaner 250

VCR 70

Water Heater 3000

Weed Trimmer 500

(a) Hard-starting motors require 3 to 5 times the rated

running watts.

(b) These loads may require up to 15 minutes to

restart due to its normal build up of compressor head

pressure.

NOTE: For extremely hard to start loads such as air

conditioners and air compressors, consult the equipment

dealer to determine the maximum wattage.

PRE-START PREPARATIONS

Your generator has been thoroughly tested prior to

shipment from the factory. However, damage can occur

during shipping, so be sure to check for damaged parts or

loose or missing nuts and bolts. If problems occur, call

Customer Service at 1-800-270-0810.

GROUNDING - All units must be grounded. Drive a

3/4” or 1” copper pipe or rod into the ground close to the

generator. The pipe/rod must penetrate moist earth.

Connect an approved ground clamp to the pipe. Run a no.

12 Ga. wire from the clamp to the generator grounding

post located on the control panel. Do not connect to a

water pipe or a ground used by a radio system.

CAUTION: The engine has been shipped without oil.

Fill the crankcase with oil before trying to start. Low oil

shutdown prevents your generator from starting without

sufficient oil.

OPERATING SPEED

The generator must be run at the correct speed in

order to produce the proper electrical voltage and

frequency. The speed of the engine was carefully adjusted

at the factory so that the generator produces the proper

voltage and frequency.

The output voltage should be checked to ensure the

generator is working properly before connecting a load to

the generator. Failure to do so could result in damage to

equipment plugged into the unit and possible injury to the

individual.

All engines have a tendency to slow down when a load

is applied. When the electrical load is connected to the

generator, the engine is more heavily loaded, and as a

result the speed drops slightly. This slight decrease in

speed, together with the voltage drop within the generator

itself, results in a slightly lower voltage when the generator

is loaded to its full capacity than when it is running with no

load. The slight variation has no appreciable effect in the

operation of motors, lights and most appliances. Electronic

equipment and clocks will be affected if correct RPM is not

maintained. See Load vs. Output chart.

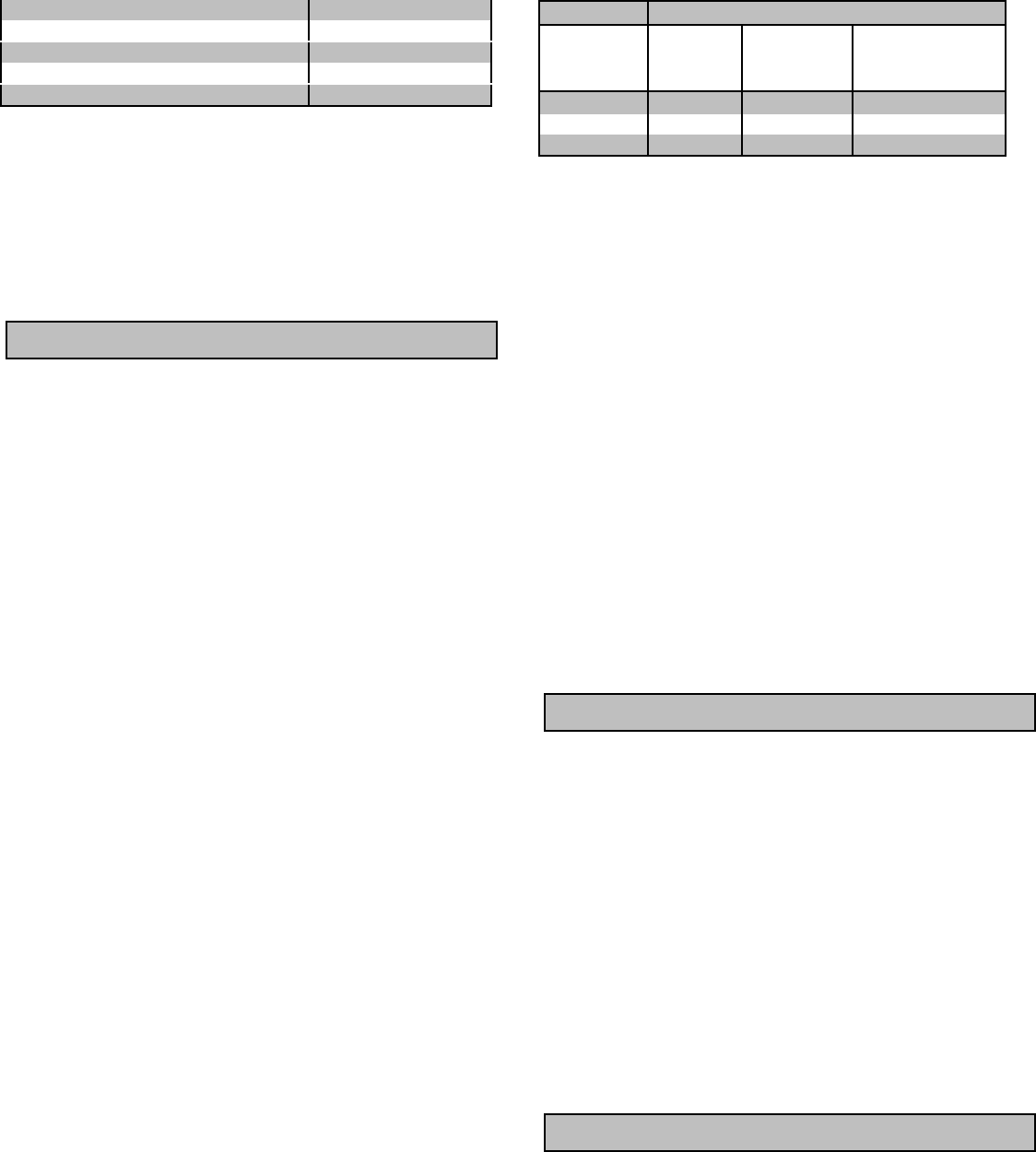

Load Output

Percent of

Generator

Output

Speed

(RPM)

Frequency

(Hz)

Generator

Voltage at 120V

Receptacle

0 % 3780 63.0 129V

50 % 3600 60.0 120V

100 % 3480 58.0 112V

Output voltage should periodically be checked to

ensure continued proper operation of the generating plant

and appliances, it can be checked with a portable meter.

Frequency can be checked using an electric clock with a

sweep second hand. Timed against a wristwatch or a

stopwatch the clock should be correct within +/- 2 seconds

per minute. A qualified techni cian should do all speed

setti ng ad ju stm en ts.

BEFORE STARTING

1. Make sure the generator is positioned on firm level

surface.

2. Check the crankcase for oil and maintain at a proper

level.

3. Check fuel level and fill tank with fresh unleaded

gasoline. Never fill fuel tank completely to the top. Always

wipe up and remove any spilled gasoline.

4. Make sure that the exhaust fumes are directed

away from people.

STARTING - MANUAL

1. Disconnect all loads to generator.

2. Turn gas line valve to ON position.

3. Turn key to the ON position.

4. For cold engine, move choke lever to full choke

position, for warm engine, move choke lever to half choke

or to RUN position.

5. Firmly grasp recoil handle and pull.

6. When engine starts, move choke lever to RUN

position.

7. Loads may now be connected to generator.

STARTING - ELECTRIC

1. Disconnect all loads to generator.

2. Turn gas line valve to ON position.

3. For cold engine, move choke lever to full choke

position, for warm engine, move choke lever to half choke

or to RUN position.

4. Turn key to start position.