MQ MP2 MASONRY SAW — OPERATION MANUAL — REV. #2 (3/12/13) — PAGE 29

A good preventive maintenance program of regular inspection

and care will increase life and improve the performance of

the saw and cutting blades.

Maintenance

MP2 MASONRY SAW — MAINTENANCE (SAW)

Basic Maintenance

1. Tighten loose nuts or screws and replace any cracked

or broken parts.

2. Clean the machine frequently. Remove the belt guard

and clean the pulleys. The belts and pulleys will wear

rapidly if excessive dust builds up.

3. Clean the sludge that accumulates on the bottom of

the water tray at least once a day and refill with clean

water. It may be necessary to clean the tray out twice

a day in heavy cutting. The sludge is abrasive and will

shorten the life of the water pump and blades.

4. After each day's use, clean the sludge from the bottom

of the tray and run clean water through the water pump

and water hoses. This extends pump and blade life.

5. Lubricate the blade adjustment rod after every eight

(8) hours of use.

6. Check the spindle bolt for tightness periodically.

7. Keep the drive belts tight. It is very important to replace

worn belts as soon as possible.

8. MAKE CERTAIN that the cutting head is aligned

properly. Misalignment can adversely affect blade life.

9. The blade flanges must have a diameter of 4 in.

Undersize flanges will reduce blade life and cause

breakage. Therefore, they should be replace at once.

Whenever cleaning, adjusting, or lubricating any part of

the saw, MAKE CERTAIN to do the following:

Electric Powered Saws

■

Place power ON/OFF switch to the OFF position.

■

Disconnect power cord from AC source.

■

NEVER attempt to check the V-belt with the engine

running. Severe bodily injury can occur.

Gasoline Powered Saws

■

Turn the engine switch to the OFF position,

disconnect the spark plug wire and secure it away

from the spark plug.

■

NEVER attempt to check the V-belt with the engine

running. Severe bodily injury can occur.

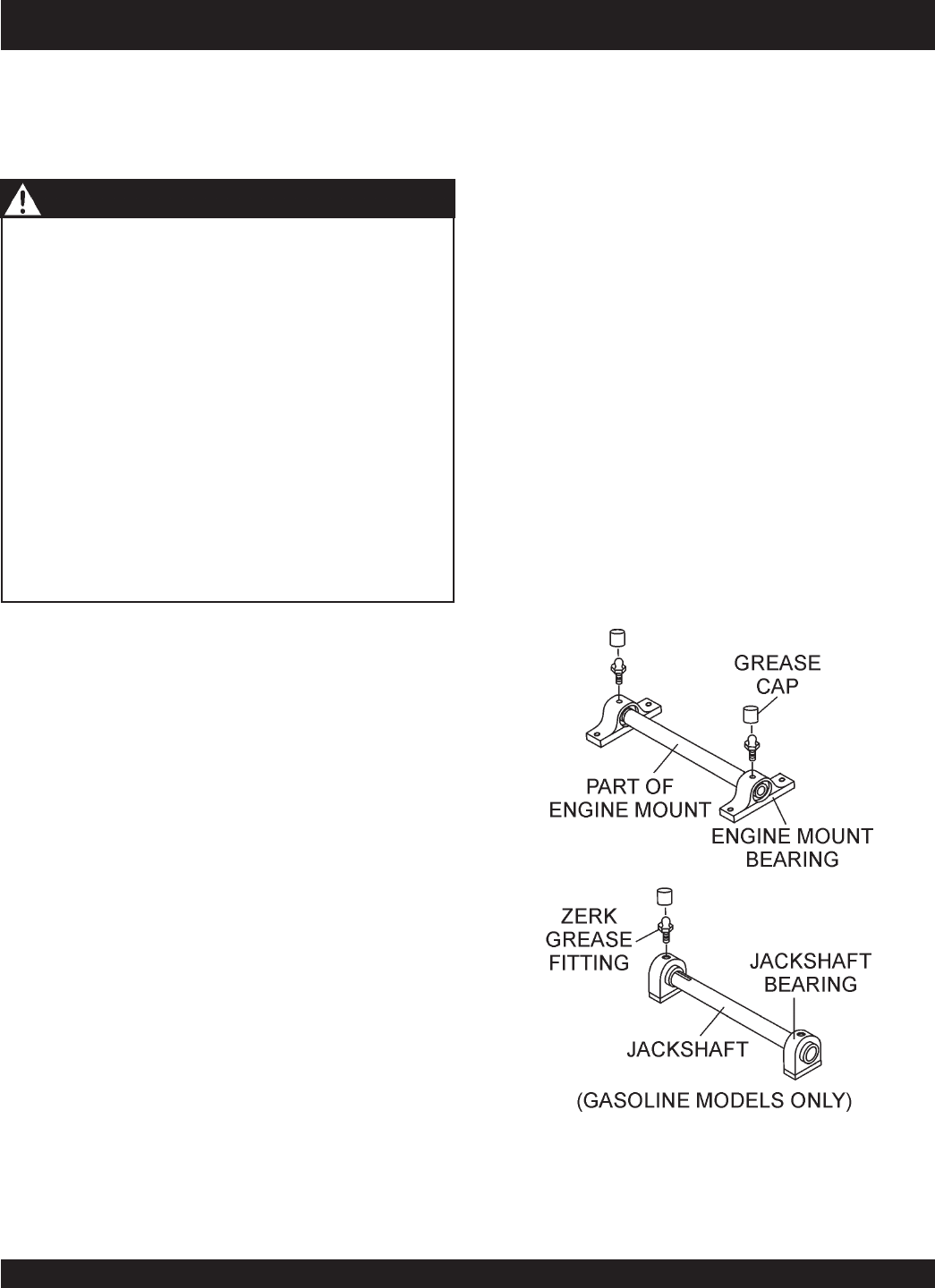

Bearing Lubrication Care

There are two (2) grease points (Figure 27) for the MP2

(Electric Motors) and four (4) grease points for the MP2

(Gasoline Engine). Use only Premium Lithium 12 based

Grease, conforming to NLG1 Grade #1 consistency. Grease

daily

.

Figure 27. Zerk Fittings (Lubrication)

WARNING - Shut-down the Saw for Maintenance

10. Cutting blades must fit the arbor snugly. This is very

important with diamond blades as pounding will occur

and serious blade damage can result. If the arbor

shoulder of the inner blade flange is grooved from blade

slippage, the flange must be replaced.

11. Inspect the conveyor cart periodically. Replace the

wood insert and wheels when necessary.

12. Lubricate spindle bearings after each day's operation.

When dry cutting, grease bearings several times during

the day's operation to protect them from the dust.

13. Replace the spindle bearings as soon as they begin to

make any strange noises. Worn bearings can destroy

blades very quickly.

14. Grease pivot bearings periodically.